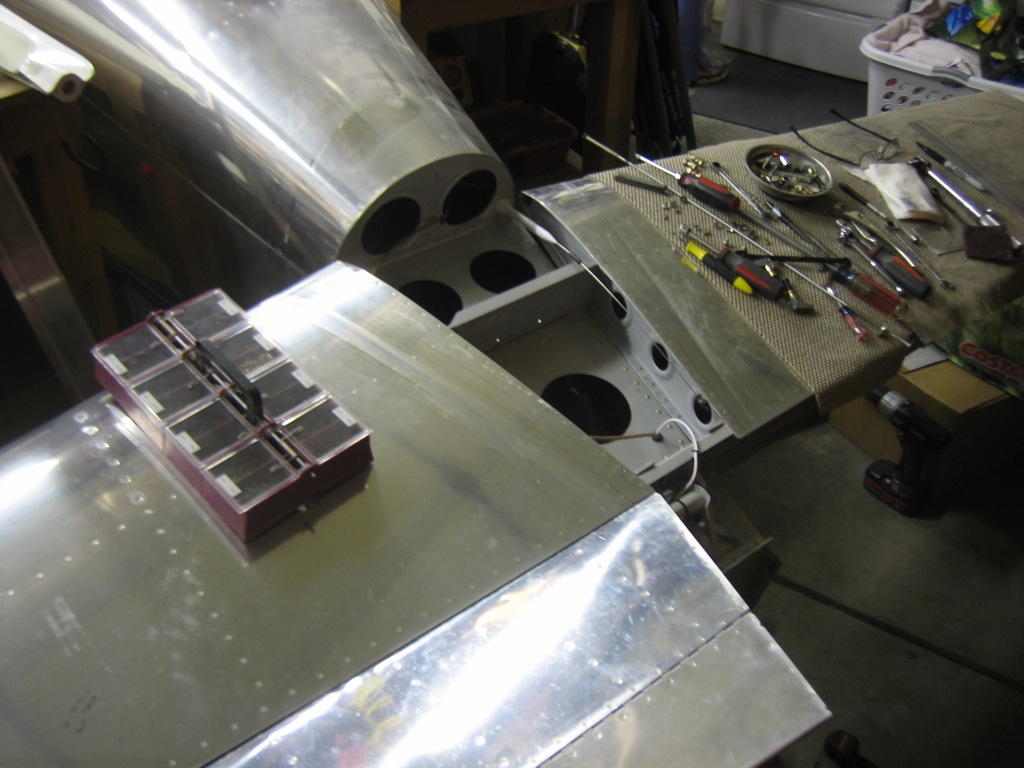

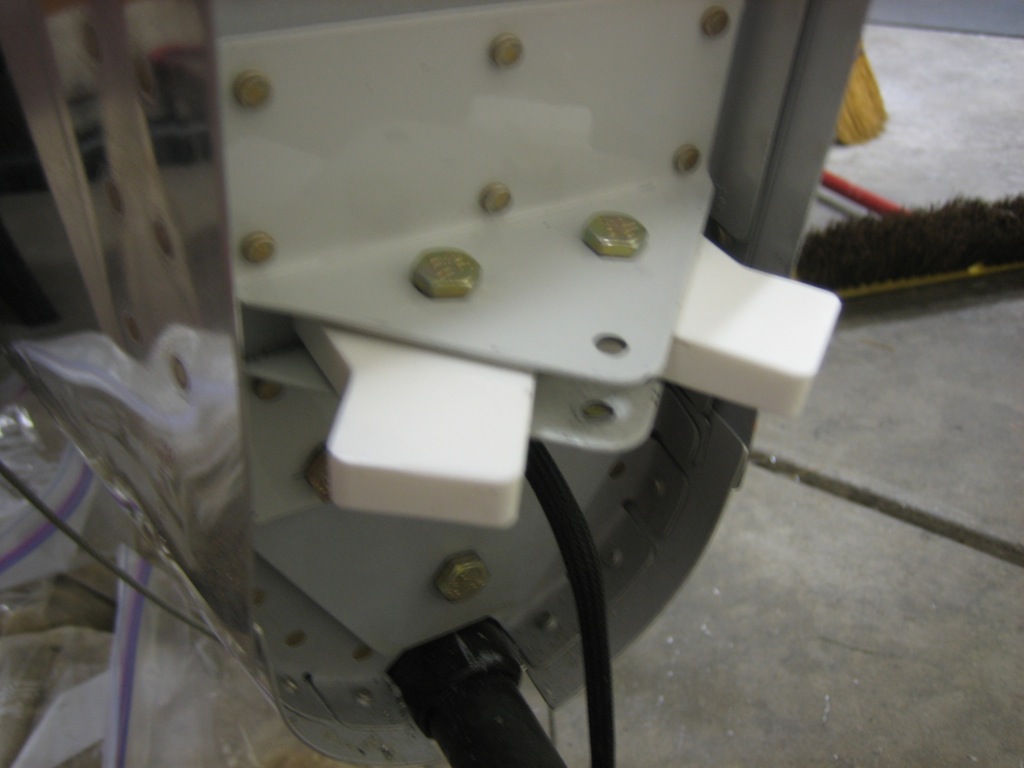

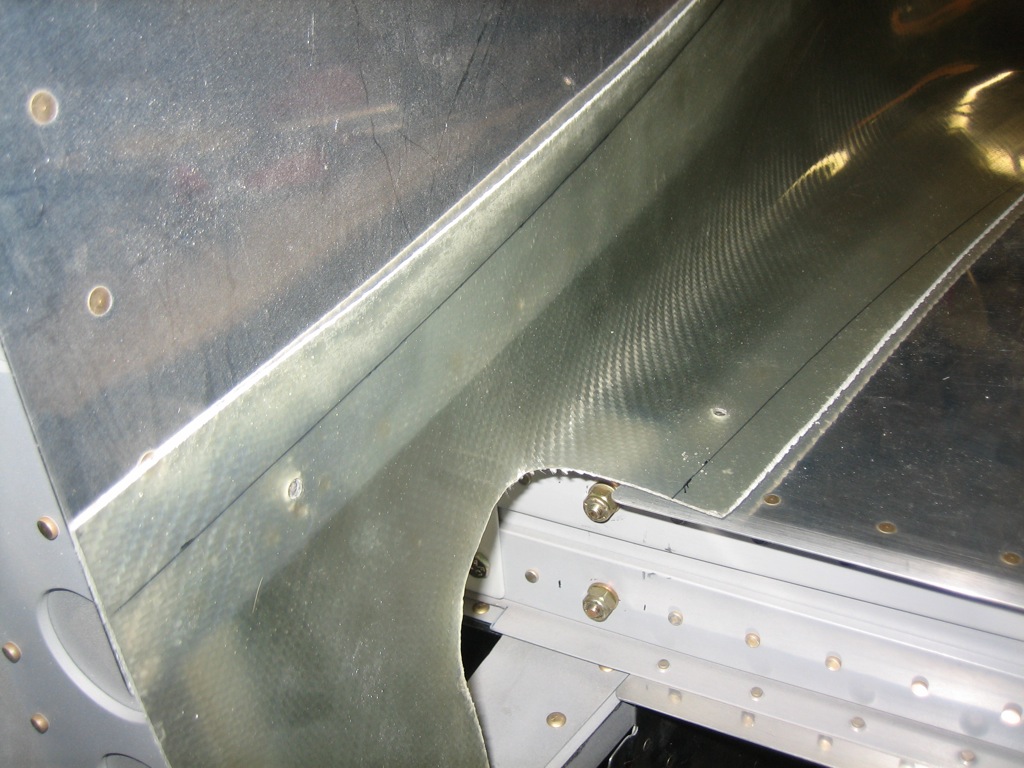

I drilled the rudder bottom fairing to the rudder and then riveted it on with some epoxy/flox.

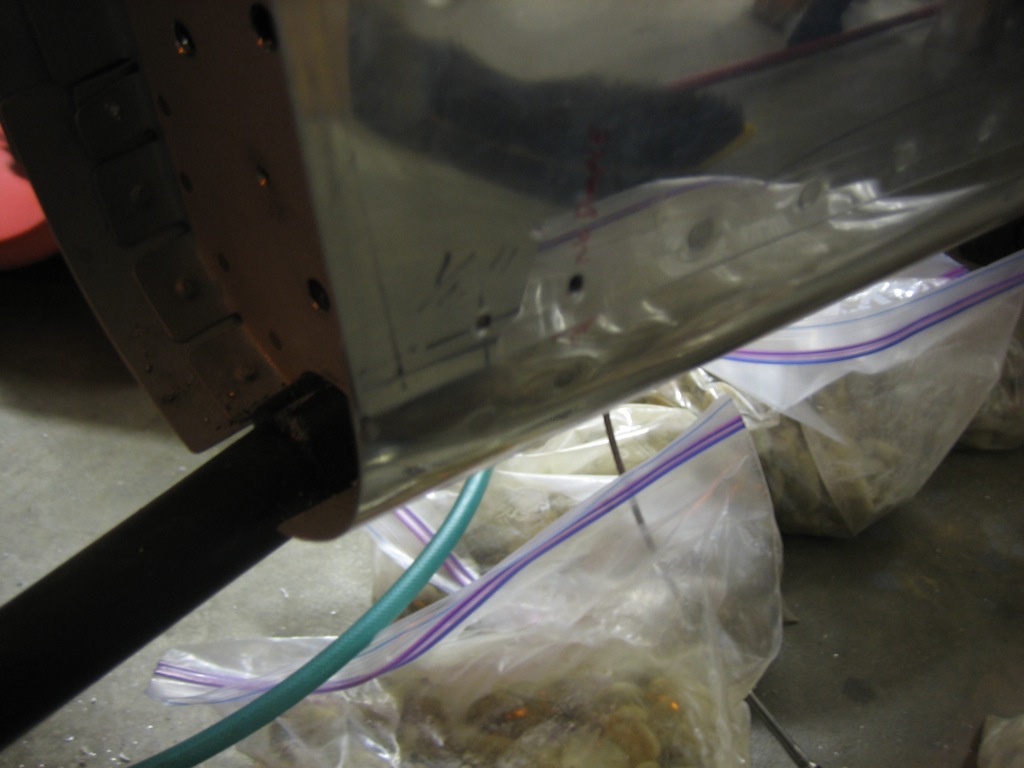

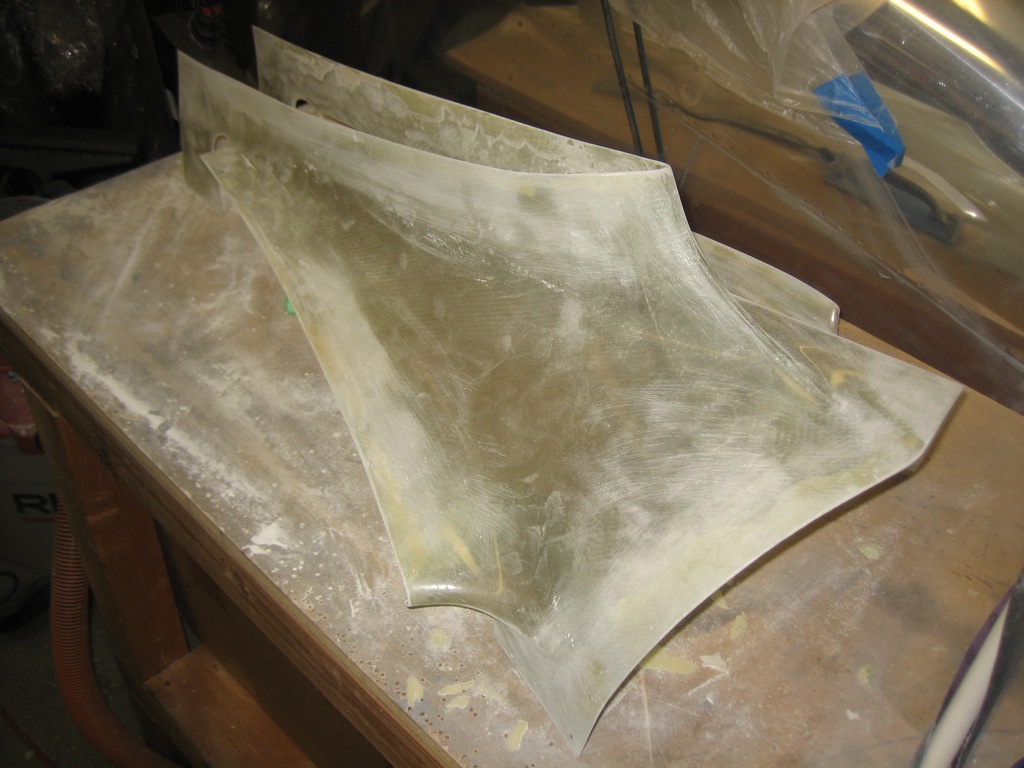

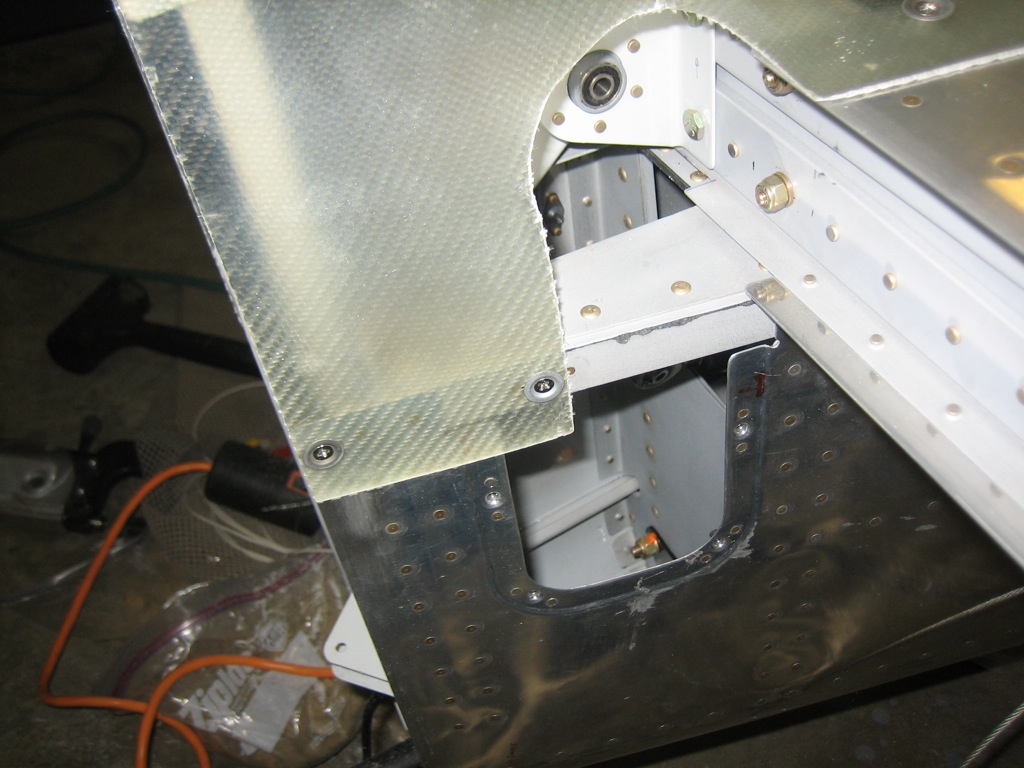

I’m going to need to trim the forward end of the fairing to clear the tail wheel spring, but I left it long so that the bottom edge will roughly align with the bottom of the fuselage. This should look better than shortening the whole fairing and making it not align with the bottom of the fuselage.

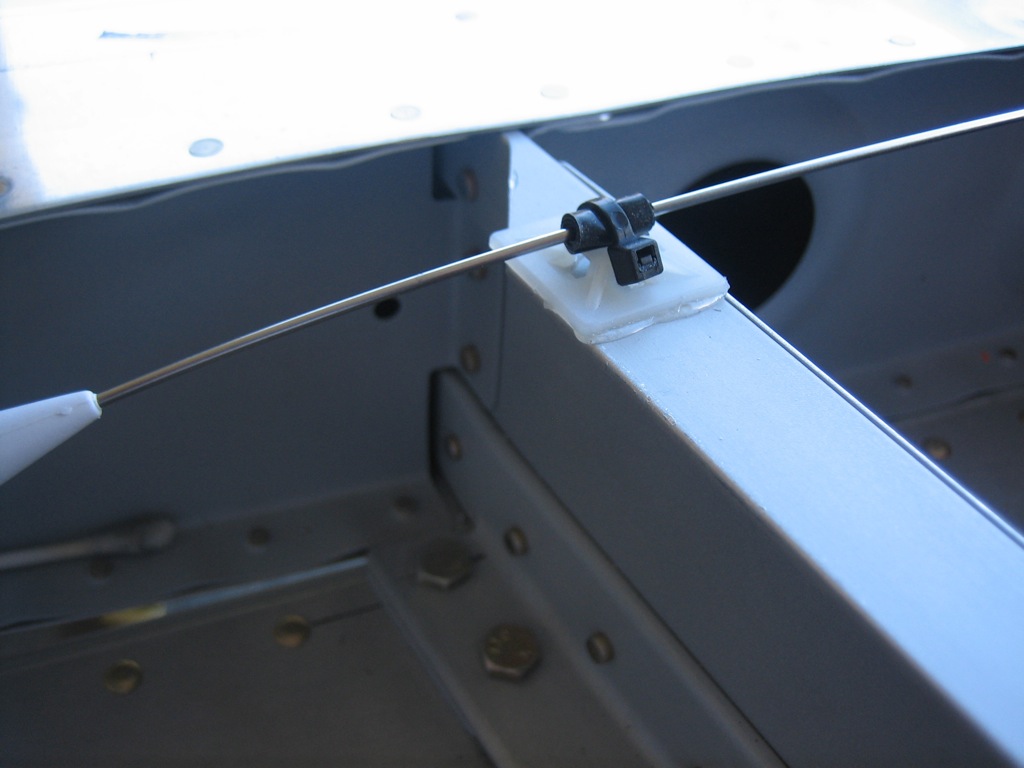

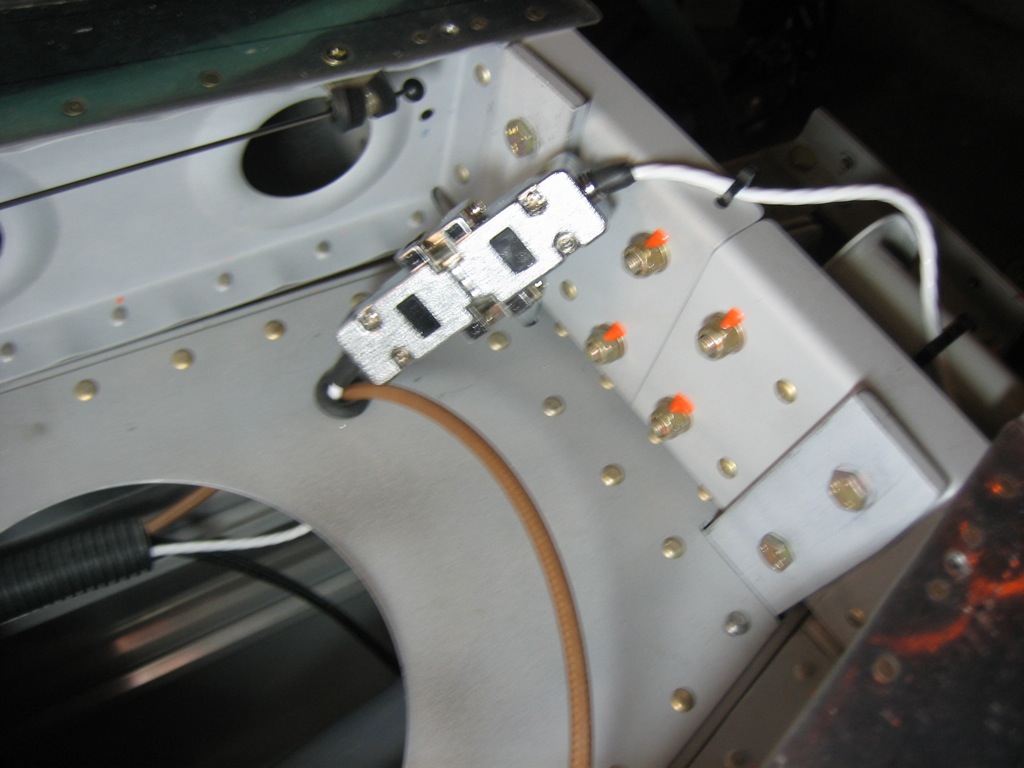

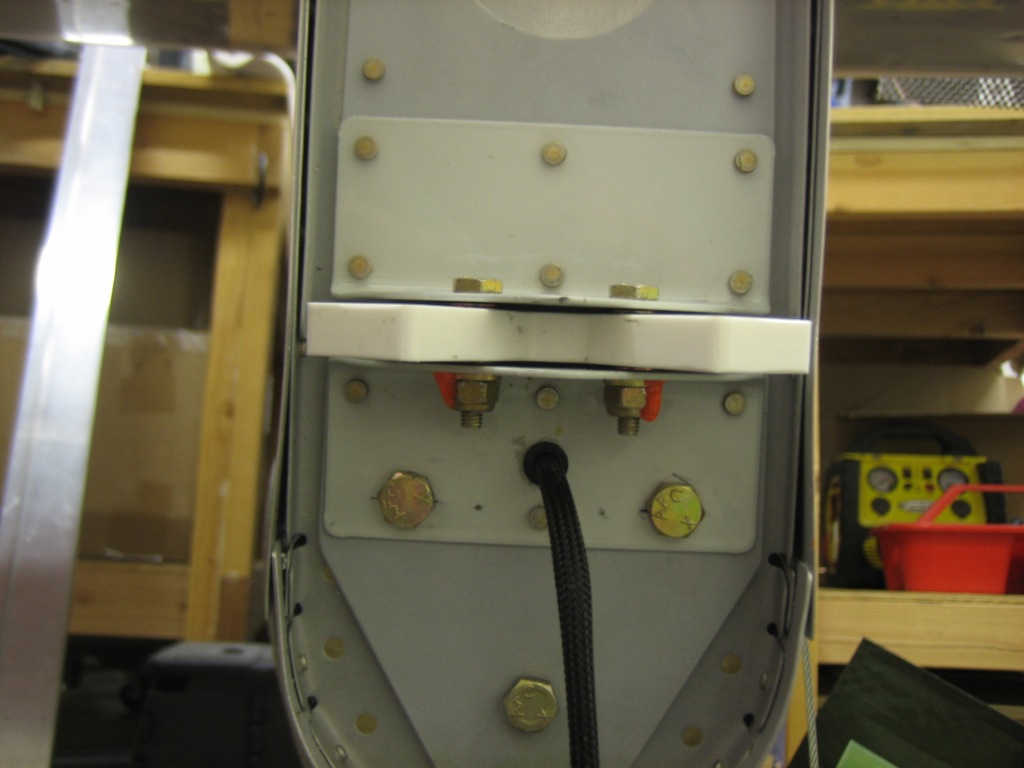

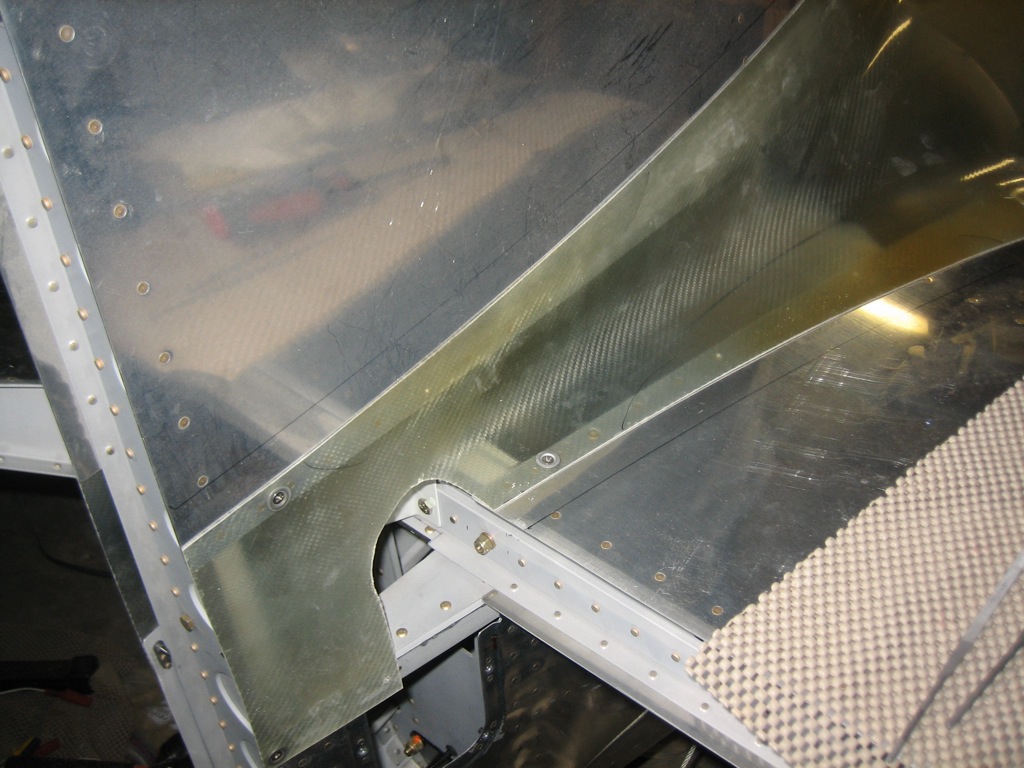

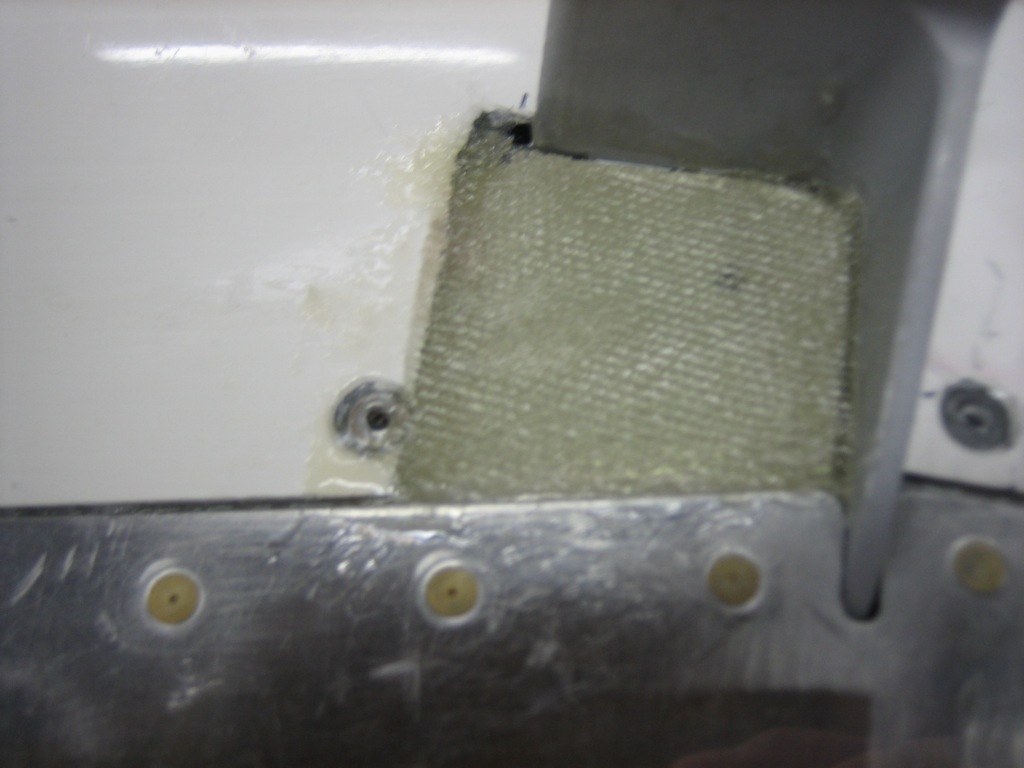

I laid in some fiberglass to fill in the gap around the control horn. I scarfed the fairing along the line on the left side and laid in four layers of 9oz glass. I also drilled a hole in the upper right that I’ll drill out and install another CS4-4 rivet through the fiberglass to prevent it from separating from the aluminum flange underneath.

Finally, I filed and sanded the fairing flush with the metal and laid a strip of 1.5oz cloth over the joint and glassed it in place. I only did this on one side; I’ll have to do the other side tomorrow.

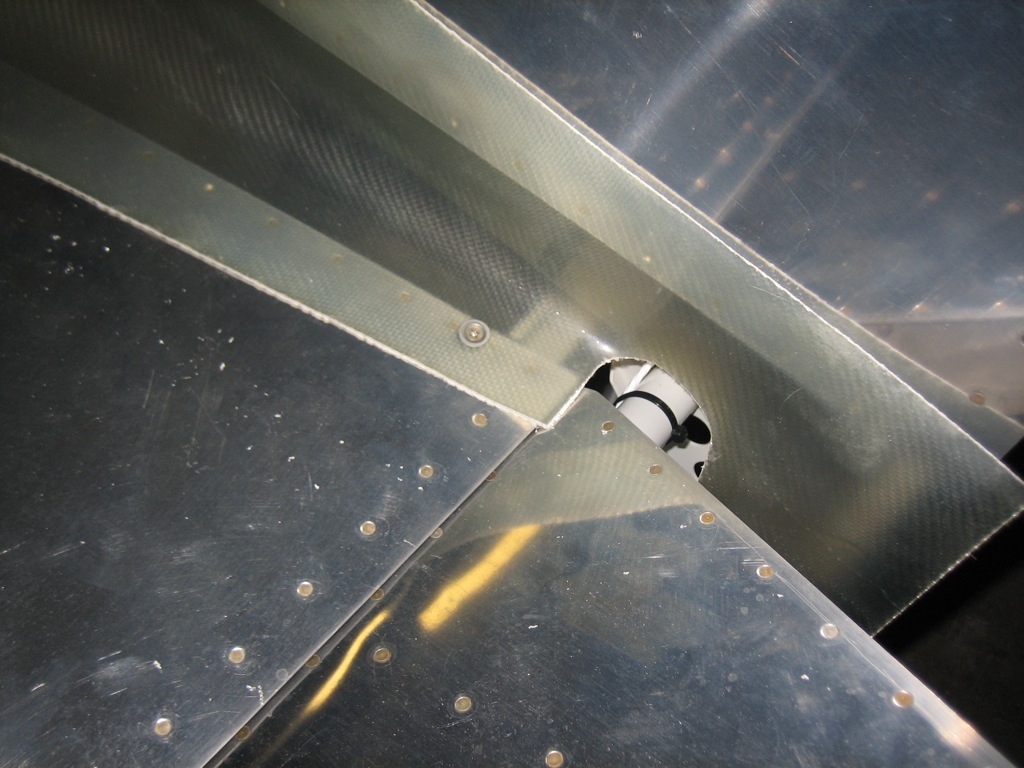

I also did the same thing at the top of the rudder. I’ll fair these in with some filler so that you can’t see the joint between the rudder and the fairings.