Before fitting the wheel pants, I needed to get the weight off of the wheels and get the fuselage perfectly level in both dimensions. Since the wings aren’t on, I can’t jack on the tie down points, and I wasn’t comfortable jacking under the firewall flange. The engine mount is plenty strong, but I didn’t just want to start jacking against one of the horizontal tubes since these are not designed to have loads placed on them perpendicular to the tubing. Right under the top of the gear leg mount tubing is an exceptionally strong portion of the mount since it handles all of the bear impact loads, but it’s not flat enough to put the jack directly on. After a little head scratching, I came up with a great way to jack against this point.

I slipped a 1/2″ socket extension through the hole in the top of the jack and wrapped a piece of MIL6000 hose around the end to pad it.

Here’s a shot looking up from underneath showing how the hose pads the jack point.

After jacking up the front, I raised the tail until the fuselage was level at the longerons. I also confirmed it’s level laterally.

I’m holding the tail up using a strap around the tailwheel spring.

The other end is wrapped around one of the rafters in the ceiling. The giant green thing is my cyclone dust collector from when the garage was a wood shop.

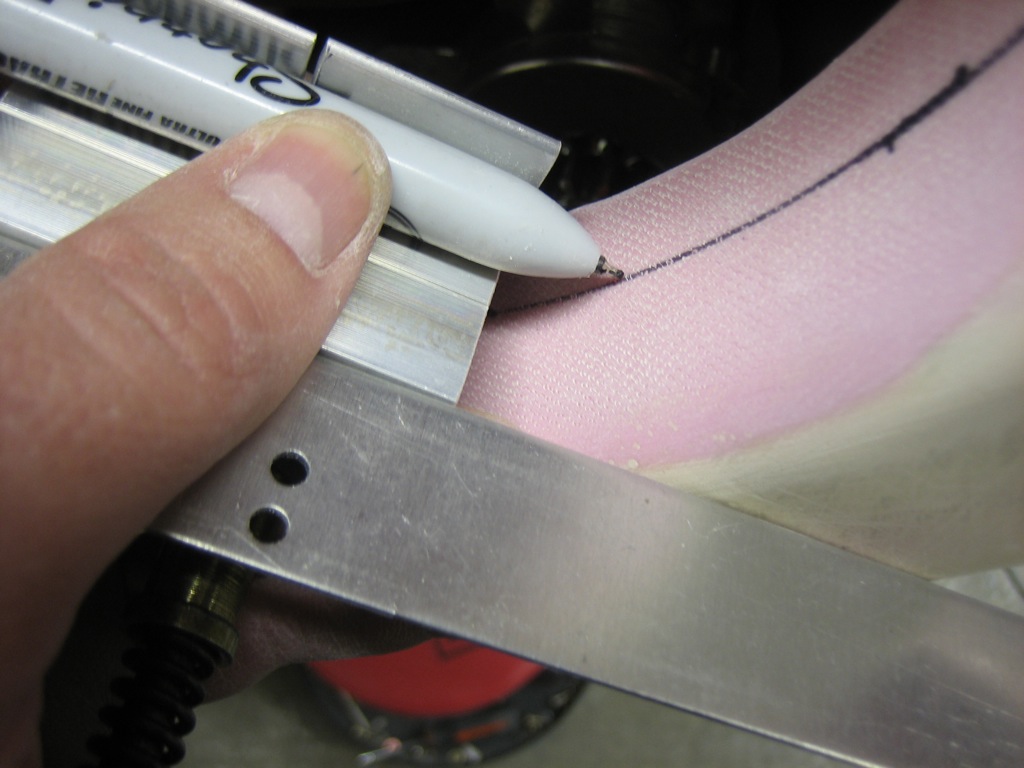

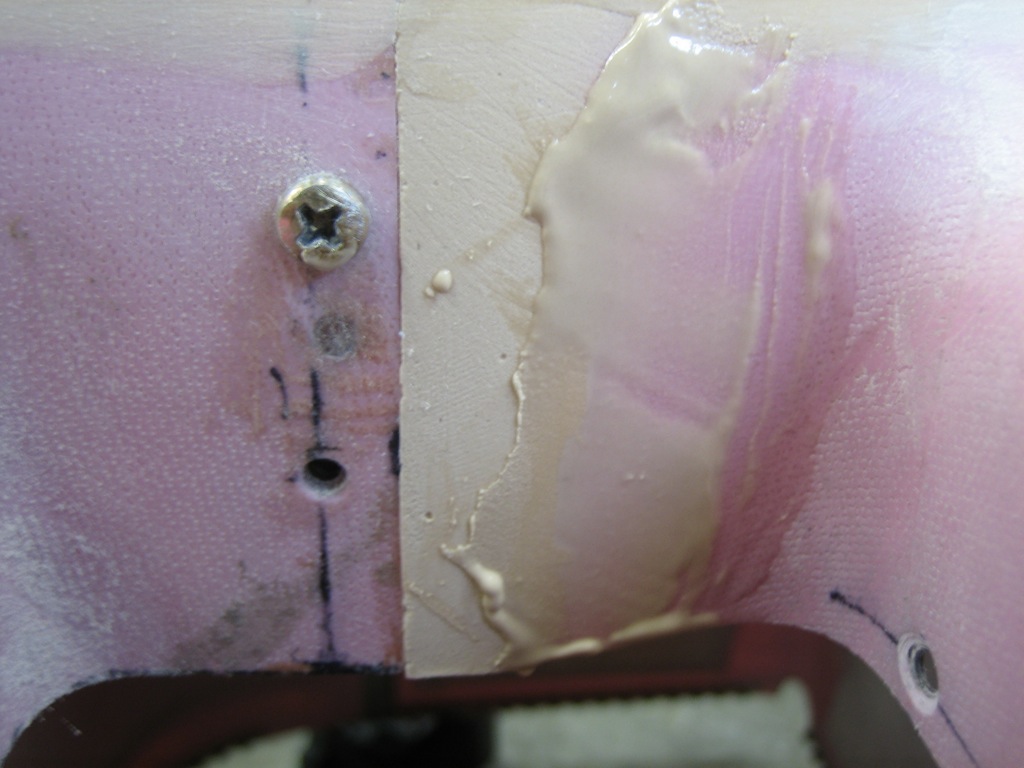

Next, I adjusted the outer wheel pant attach bracket to be perpendicular to the floor using a carpenter’s square.

The wheel pant needs to be 1″ above the top of the wheel. I hunted around the shop for a bit and found these old wooden knobs. I taped a washer to the end to bring them up to exactly 1″ thick.

These will sit on the top of the tire to keep the wheel pant the appropriate distance away. After this, I used a long piece of duct tape to temporarily attach the knob to the tire.

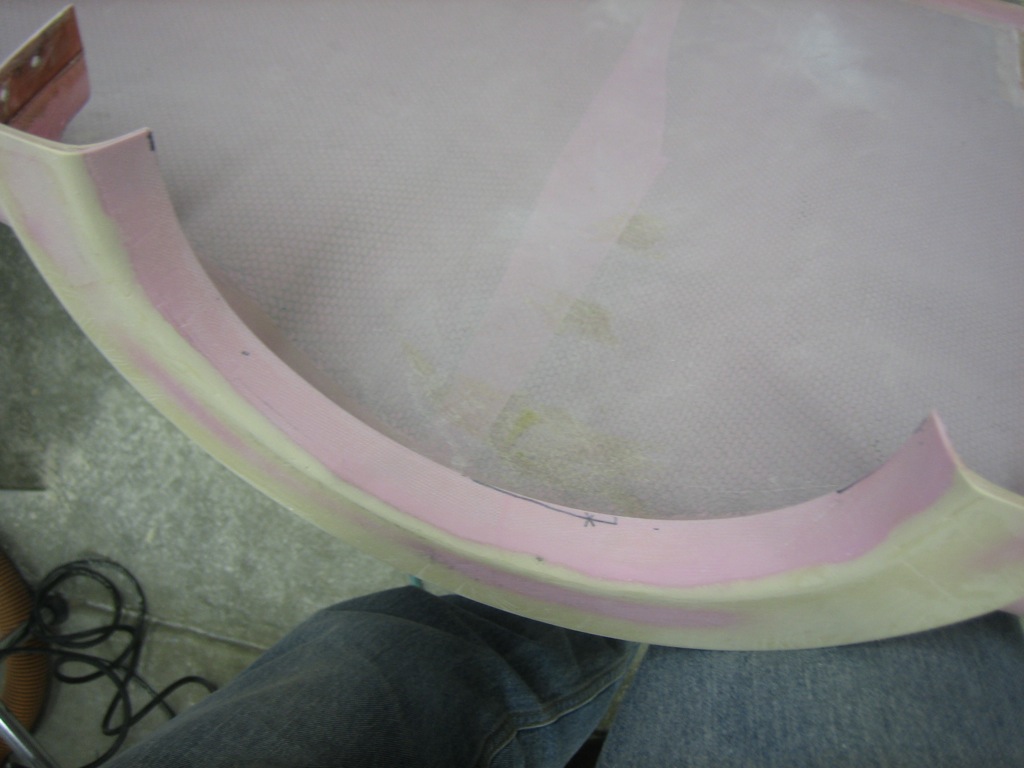

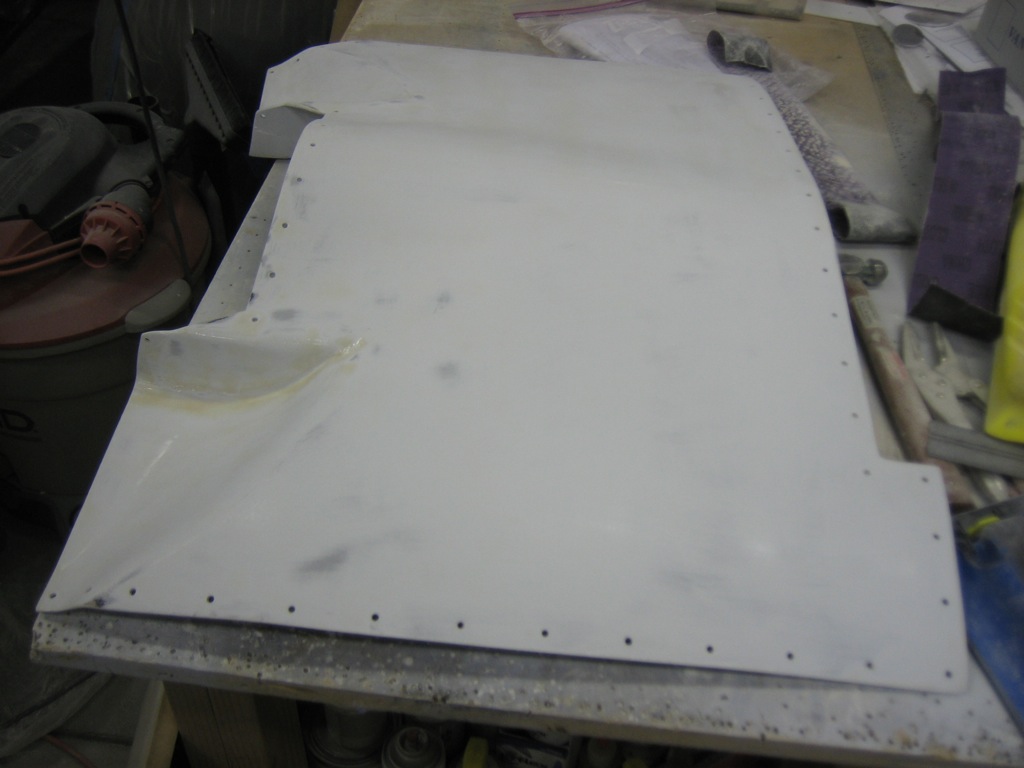

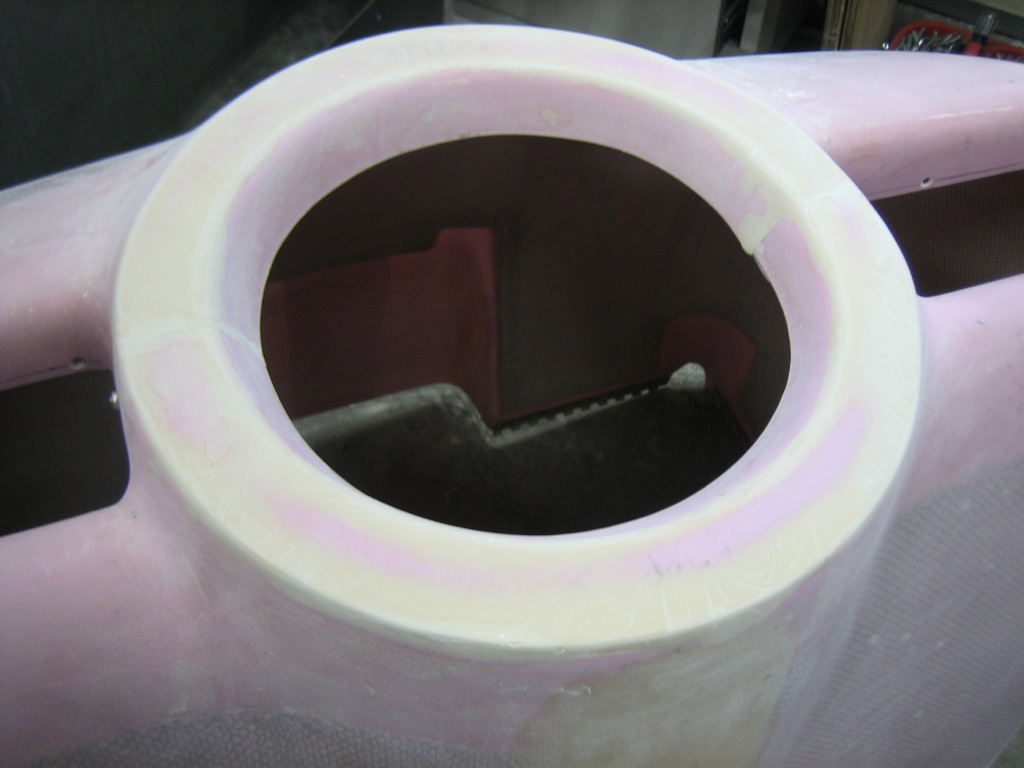

After opening up the hole on the bottom for the tire and trimming a relief on the inside for the gear leg, I fit the wheel pant for the first time. This is going to require quite a bit of adjustment, but it’s approximately the right position here.