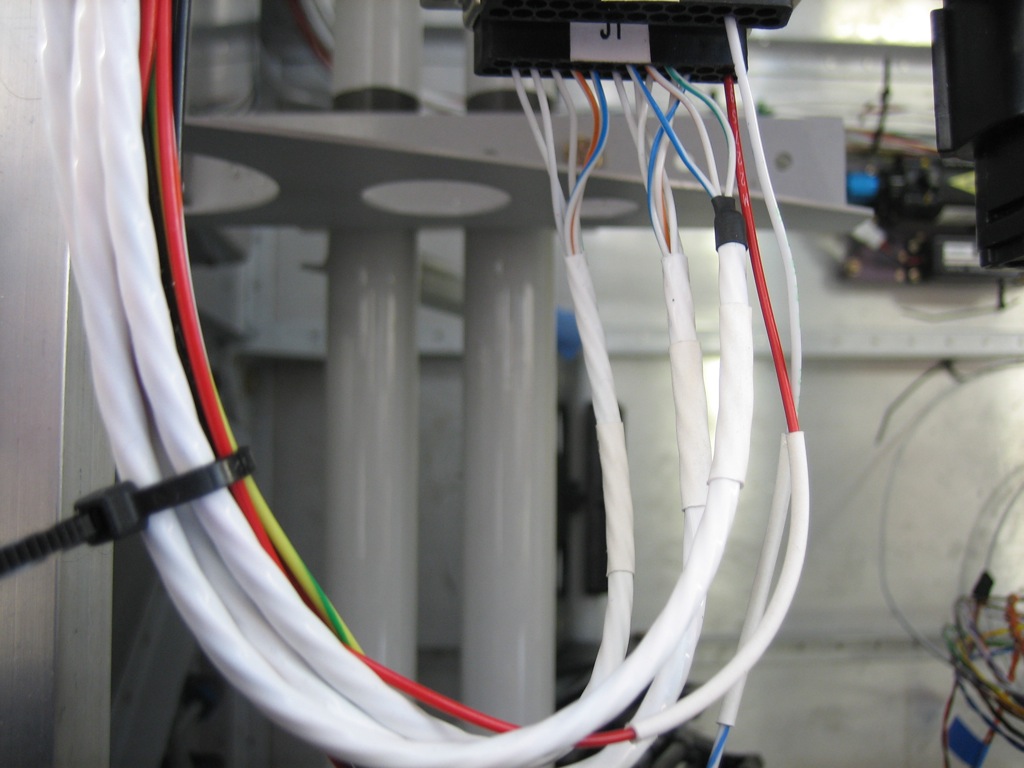

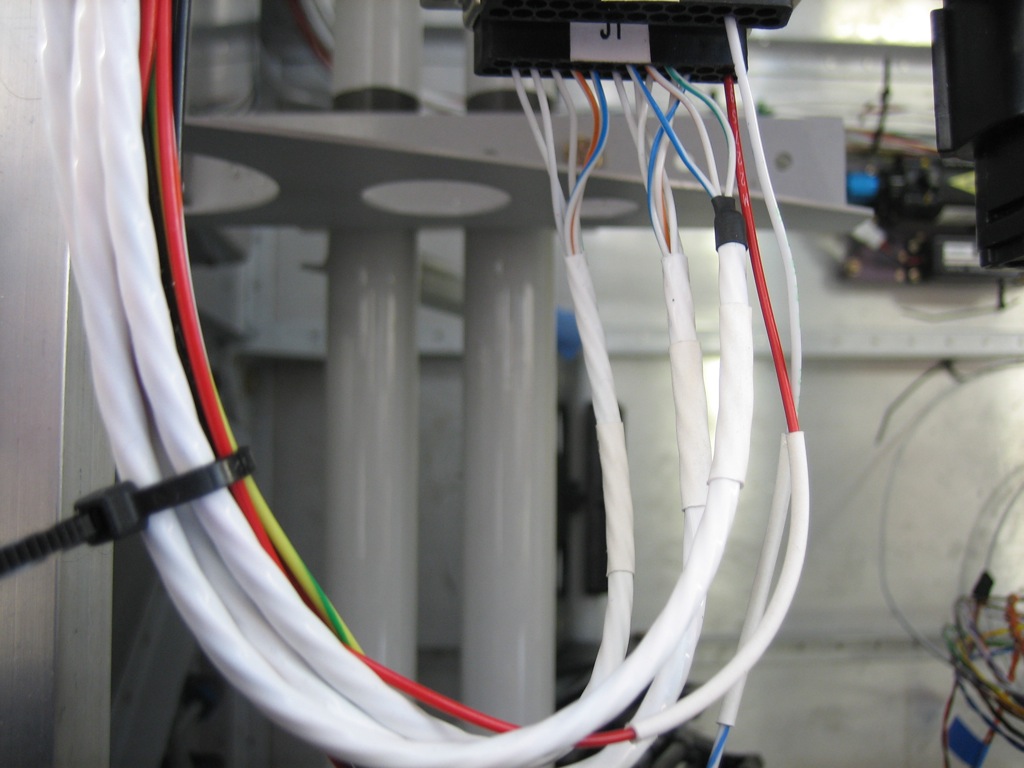

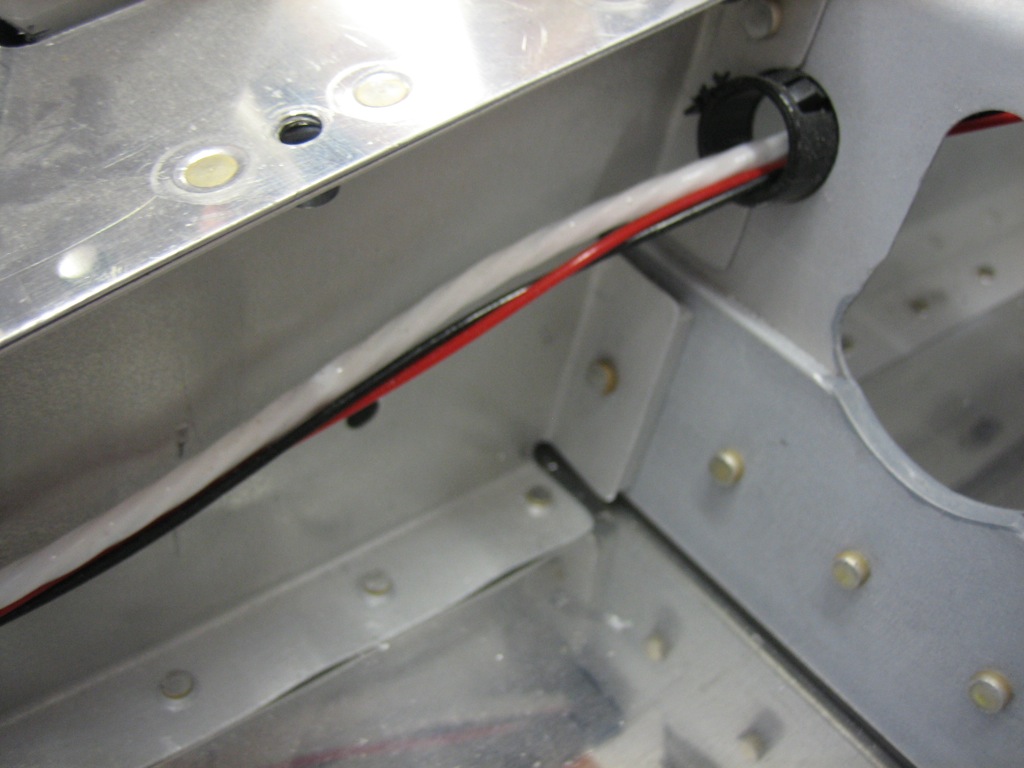

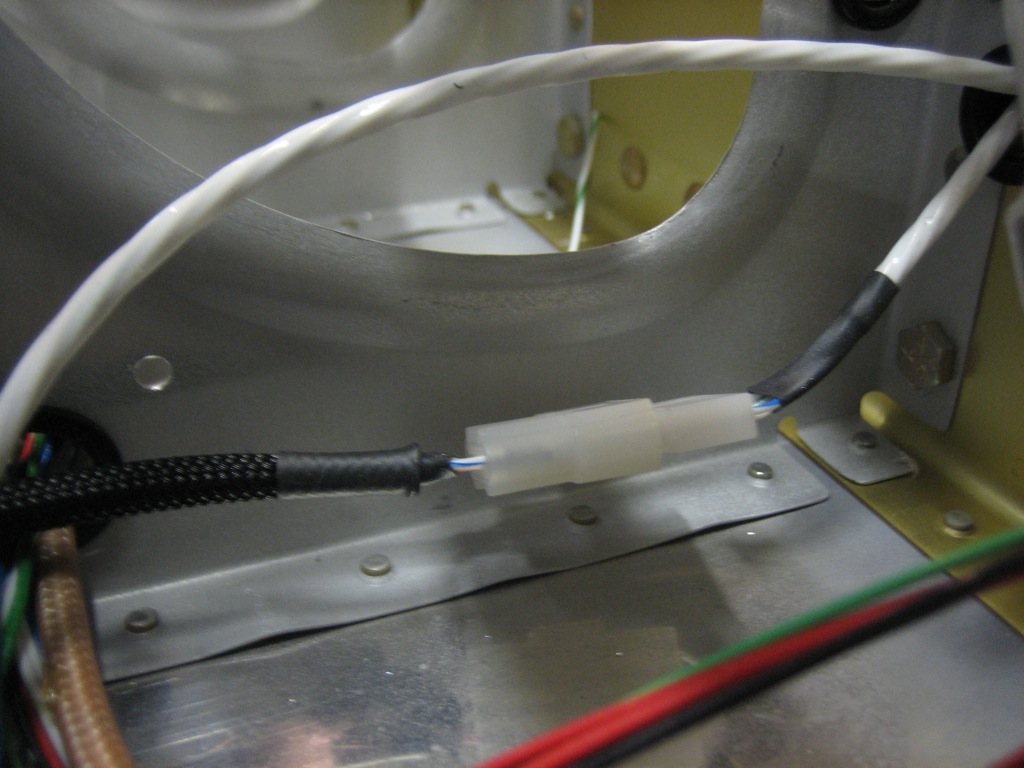

Since I had some extra trim servo cable, I replaced the three wires from the VP-X to the flap position sensor. I’m trying to keep all wires color coded where possible and these were three wires that didn’t match up with the colors on the sensor.

Since I had some extra trim servo cable, I replaced the three wires from the VP-X to the flap position sensor. I’m trying to keep all wires color coded where possible and these were three wires that didn’t match up with the colors on the sensor.

One of my old college buddies Matt was in town this weekend to visit. I was hoping we’d have more time to work on the plane, but at least we had a little.

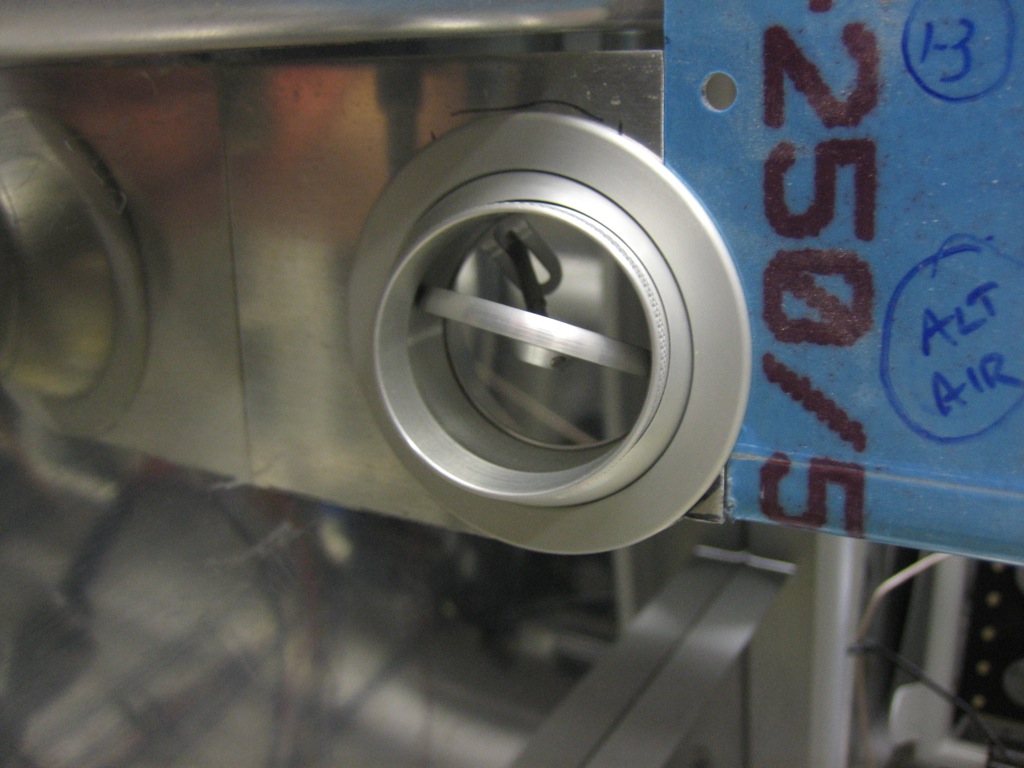

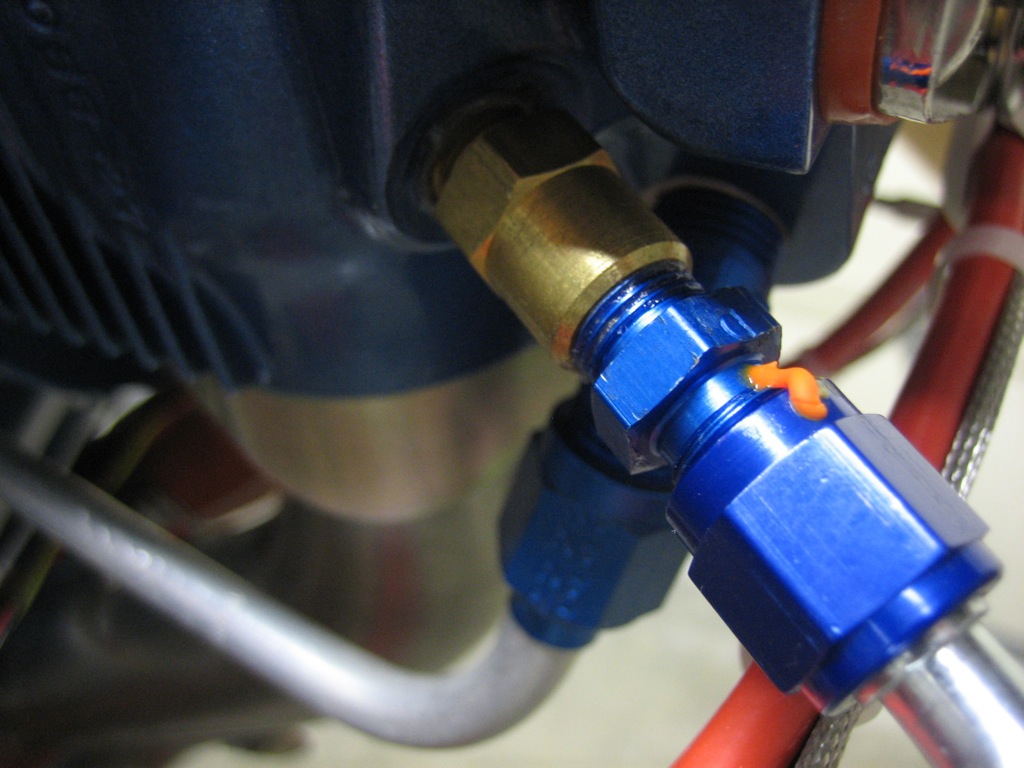

I received this brass restrictor fitting from Wick’s Aircraft today. It has a 0.040 hole drilled in the middle to dampen out the pressure changes so that the manifold pressure sensor reading doesn’t fluctuate wildly. Wick’s has a $15 minimum order, so I had to pay an extra $5 fee since this is all I ordered. I was going to add a couple of other parts onto the order that I need so that I didn’t need to pay the fee, but their prices are substantially higher. Companies with minimum order sizes piss me off anyway, so this will be the last time ordering from Wick’s if I can help it.

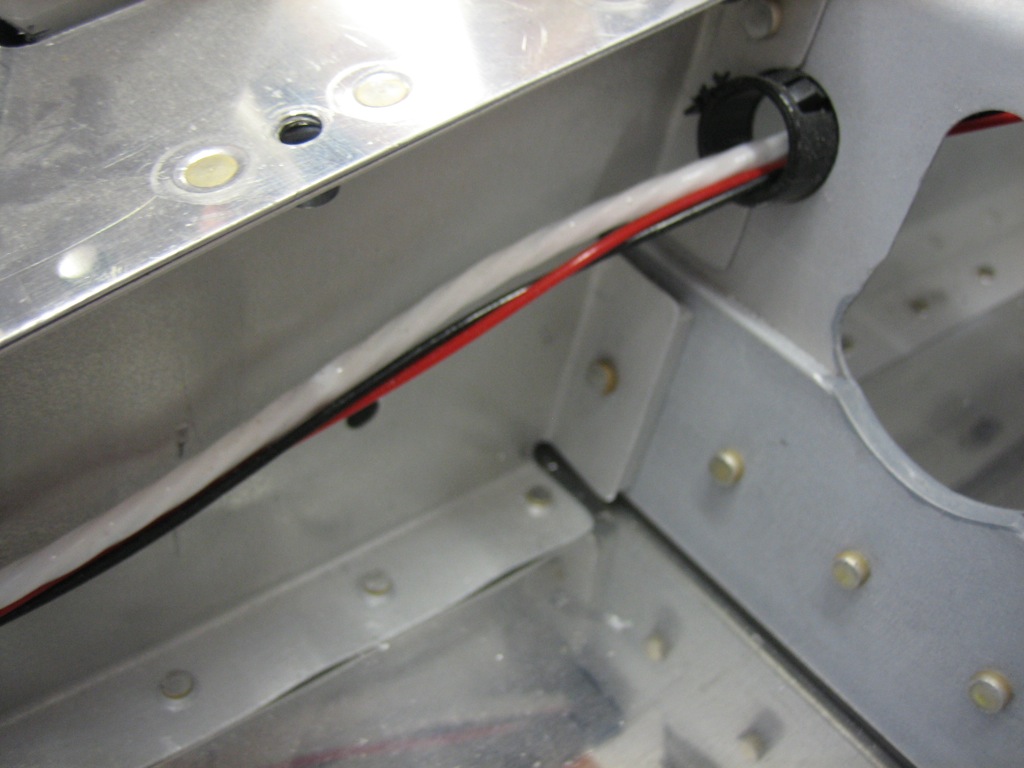

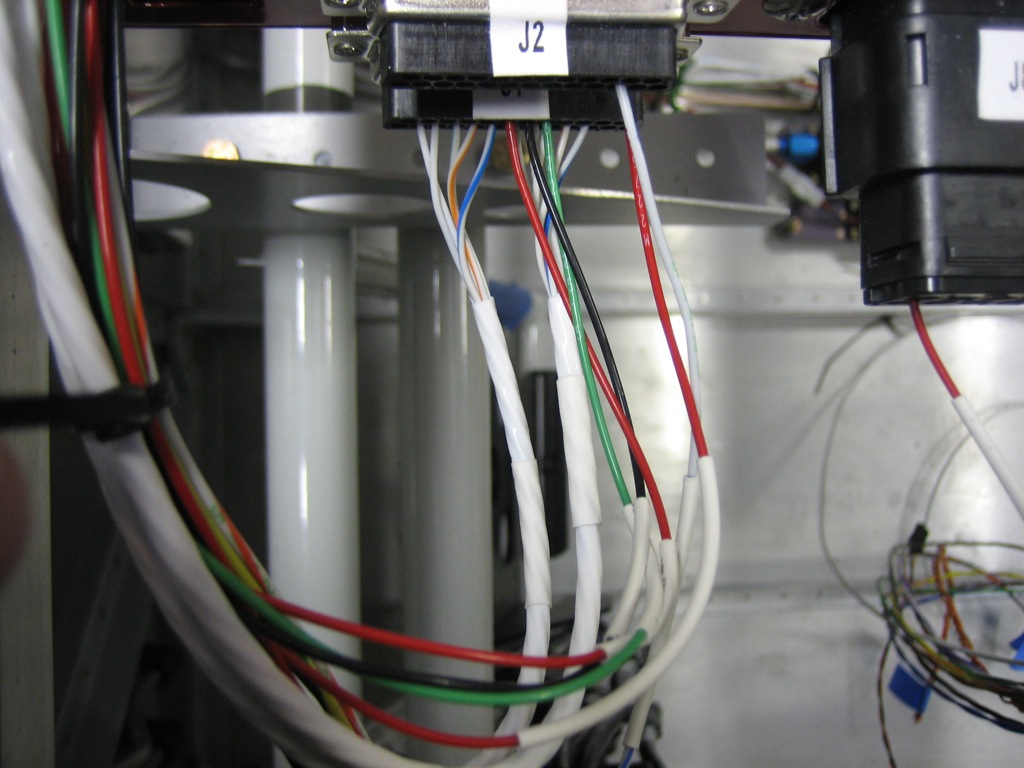

I also got an order from Aircraft Spruce with some more Ray Allen servo cable for the aileron trim. Matt helped install the connectors on the ends and I wired it to the VP-X alongside the pitch trim cable.

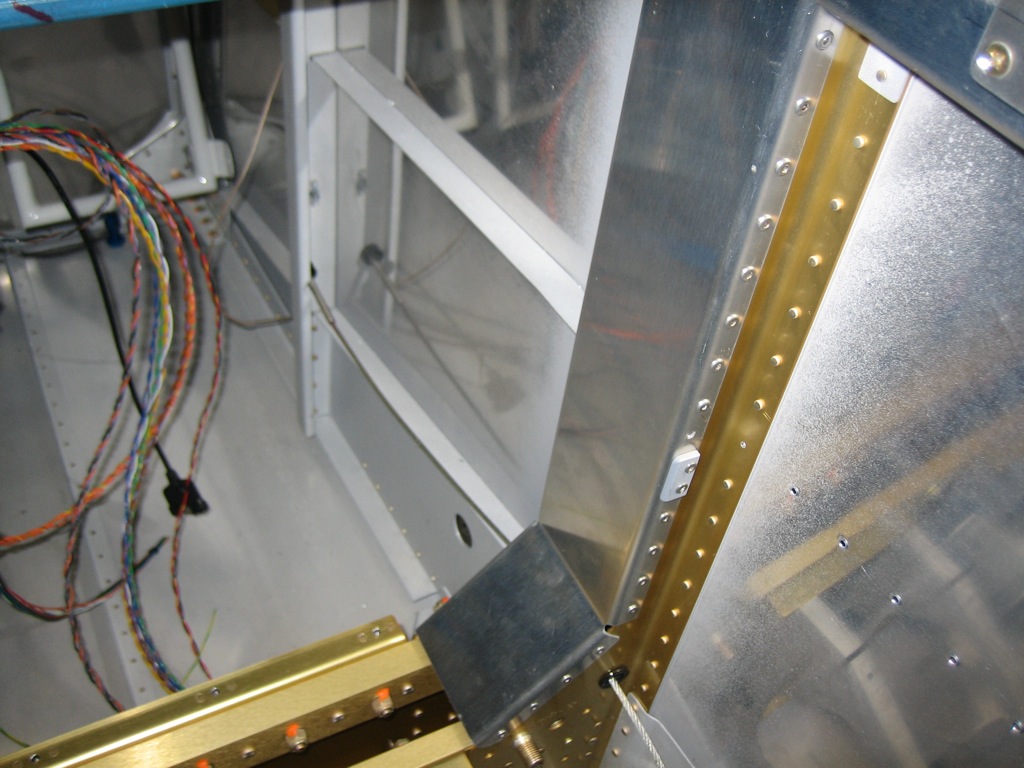

Under the seats, I installed a 5 position molex connector to attach the cable to the aileron trim servo.

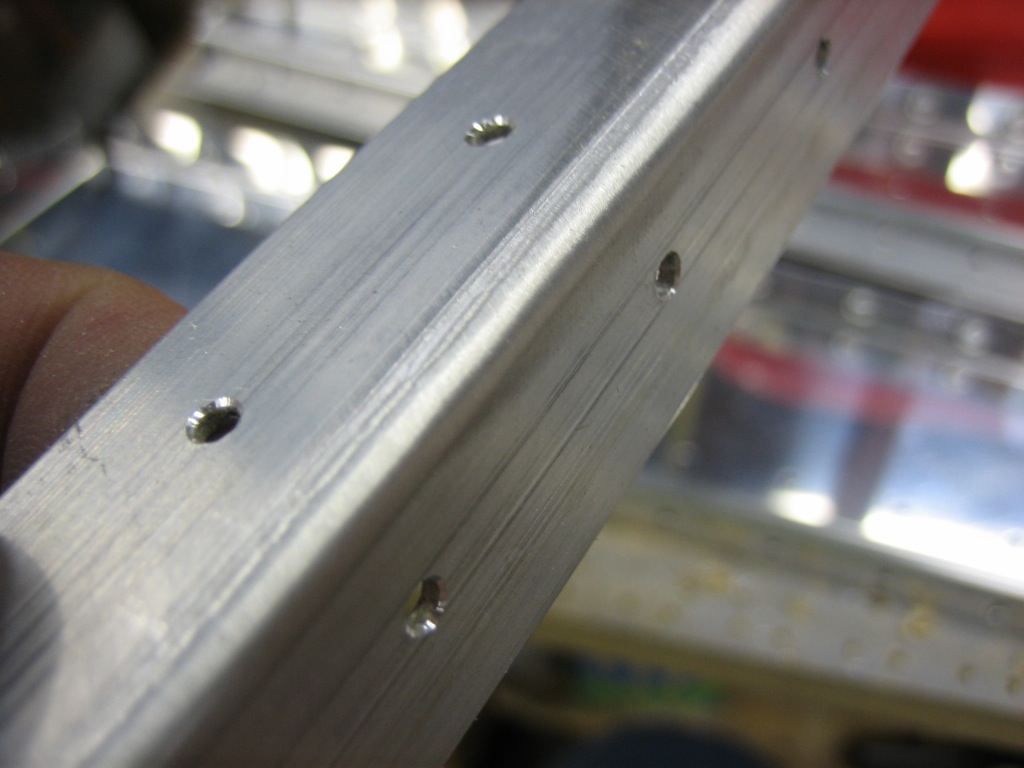

I countersunk the reinforcement angles and dimpled the armrests. After edge finishing the armrests, I primed and riveted the parts together.

I finished drilling and deburring the reinforcement angles to the armrests. Rivets will be spaced on roughly 1″ intervals on the top and side of the angles.

No pictures tonight, but I worked on the left cap strip tonight and got all the parts deburred and primed.

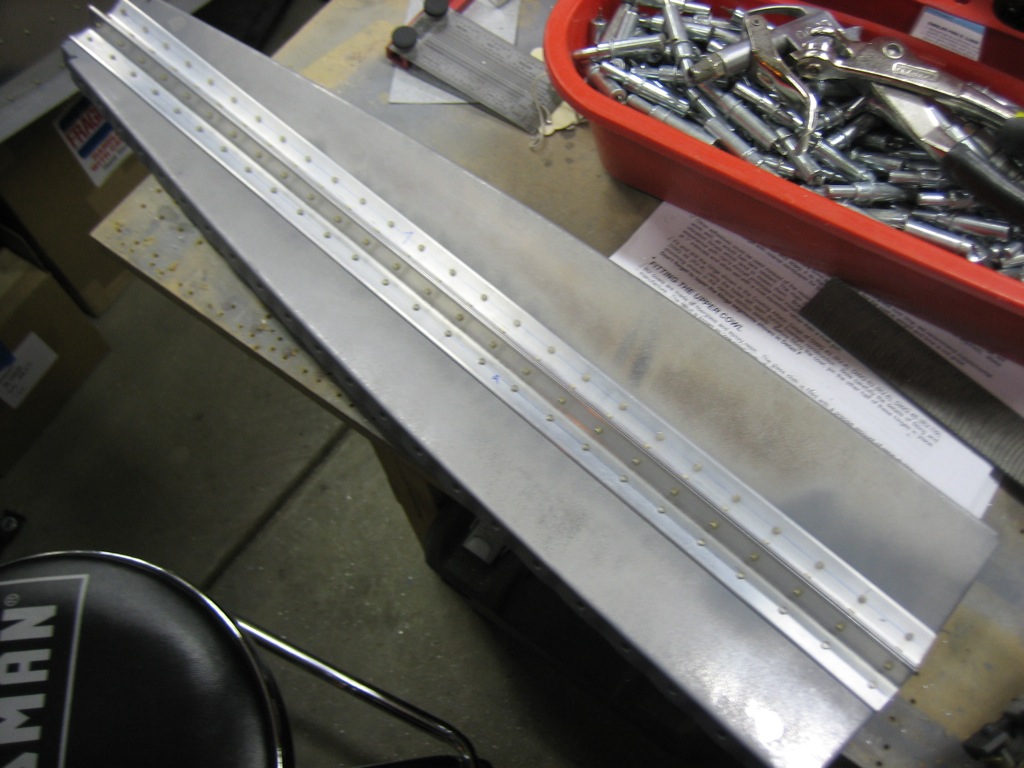

I riveted the right cap strip in place. Doing this many pop rivets in a row with a hand pop-riveter is a killer on the hands and forearms. I really wish I had purchased a pneumatic pop-riveter near the beginning of the project. There are probably not enough remaining pop rivets left on the plane to justify purchasing one now though.

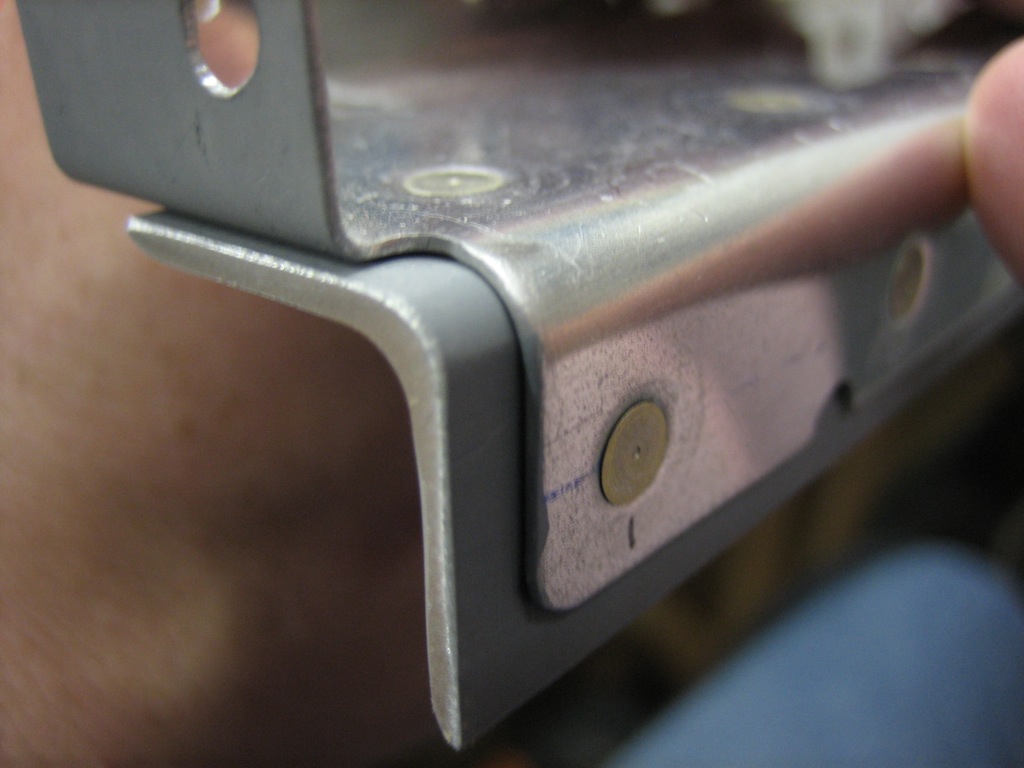

Here’s a closeup of the forward armrest support.

And here’s the aft armrest support for the right side. I installed this with solid rivets since I had access to the back side.

The armrests are pretty flimsy as designed. I’m using some 0.063″ angle to reinforce them. I used a router to radius the outside corner so that it can tuck into the angle on the armrest. I drilled them to the flange and will eventually also drill them to the top surface of the armrests.

I also fabricated four of these little supports that will rivet into the bulkheads at each end of the armrests to transfer the load directly into the bulkheads instead of through the wimpy flanges on the armrests.

Here’s how these will mount. Any load on the armrests will be transferred into the 0.063″ angle. The angles will sit directly on top of the supports to transfer the load into the bulkhead. Without these, that little flange just above the angle would have to carry the load.

After a handful of lessons in a Citabria at Aerodynamic Aviation, I got my tailwheel endorsement this morning! I’m hoping to rack up 20-30 tailwheel flight hours before doing my RV transition training later this fall.

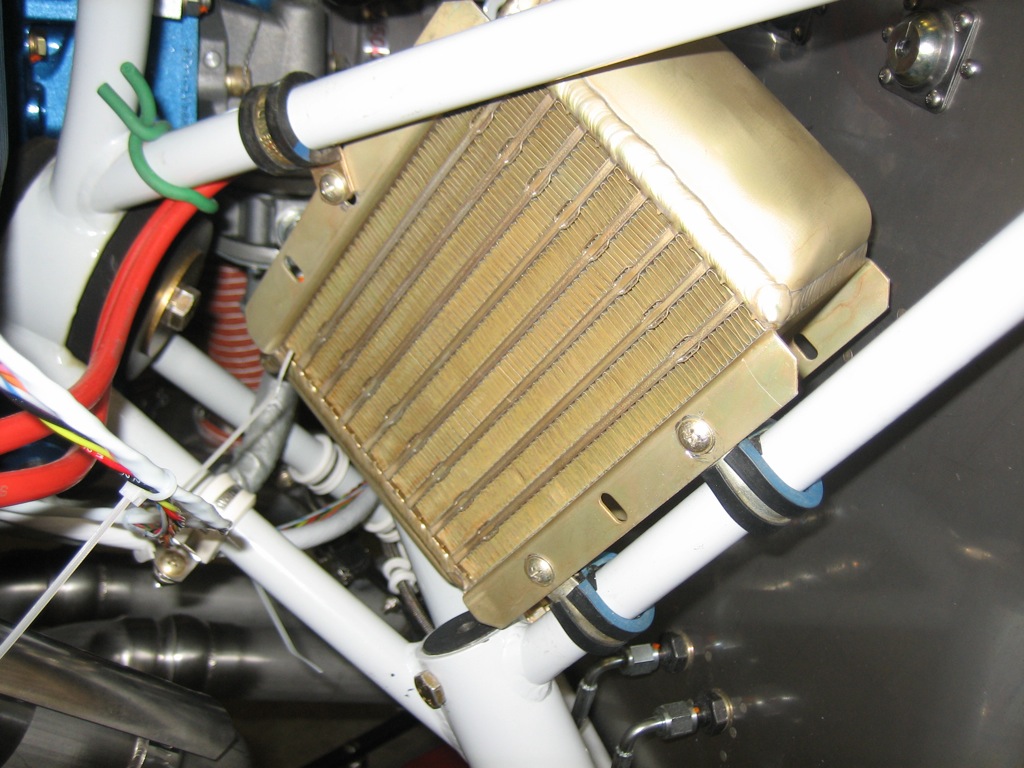

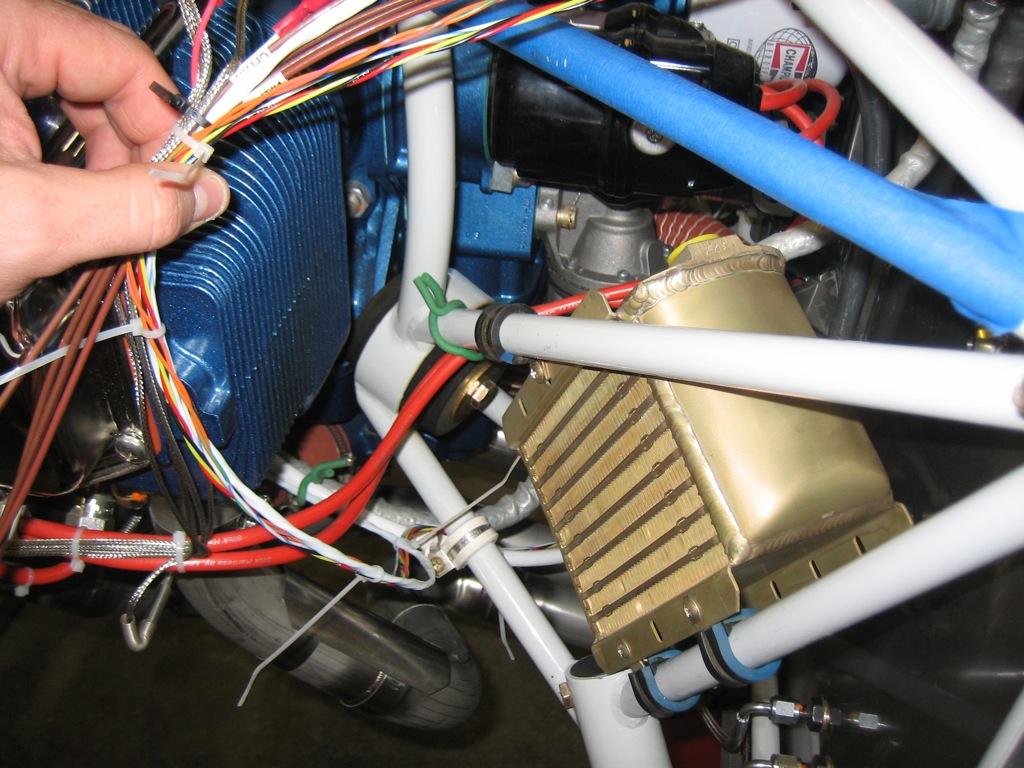

I’ve been toying with various install locations for the oil cooler. I would prefer not to mount it on the baffles for a couple of reasons. First, it’s really tight there because of the size of the 10559R oil cooler. Second, people already have problems with the baffles cracking due to the weight of the oil cooler. Since this oil cooler is larger than typical, it will contain more oil and will therefore weigh even more than normal. I would have to reinforce the baffles even more than builders normally need to carry the extra weight.

I tried various positions on the firewall, but things are really tight there. There is one spot that could work, but it would require building a custom bracket and significantly reinforcing the firewall. After playing with various mounting locations, I stumbled on the possibility of mounting it between two of the engine mount tubes. I mounted it temporarily using a few adel clamps to see if it would work. There’s a little bit of flex, but this is surprisingly strong. I can move the entire plane by pushing and pulling on this. If I go with this location, I’ll move it down a little bit and fabricate a bracket that lets me use two adel clamps on the top flange to prevent twisting. This will give me a little more clearance for the control cables as well as make the upper engine mount tube be a little move out of the way.

You can see that there is plenty of room between the back of the engine and the oil cooler. I will mount a flange on the back of the baffles (either 3″ or 4″) and run some scat tube down to a custom plenum that I will fabricate to direct the air through the oil cooler. I want to sleep on it and run it by the folks on vansairforce.net to make sure there aren’t any issues with this plan.

The fuel pressure line runs right by the back side of the oil cooler. I’ll install an adel clamp here to space the line a little bit away from the oil cooler flange.