I won’t have any updates for a week or so because I’m heading to Oshkosh tomorrow morning.

Finished Canopy Hinge Blocks

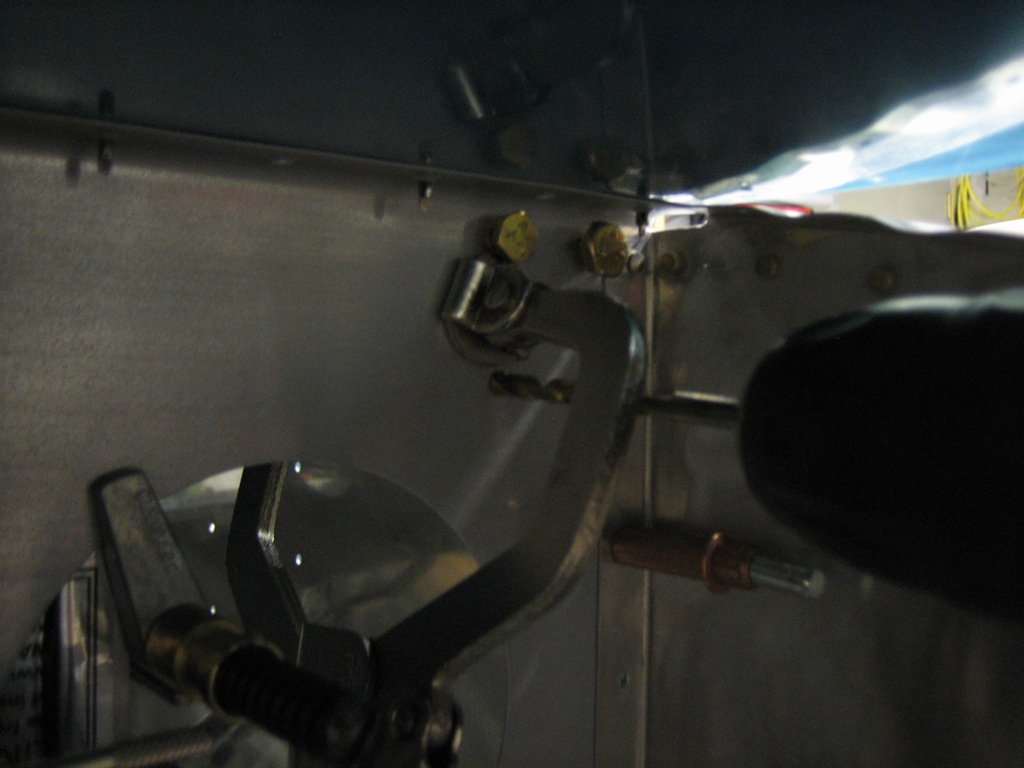

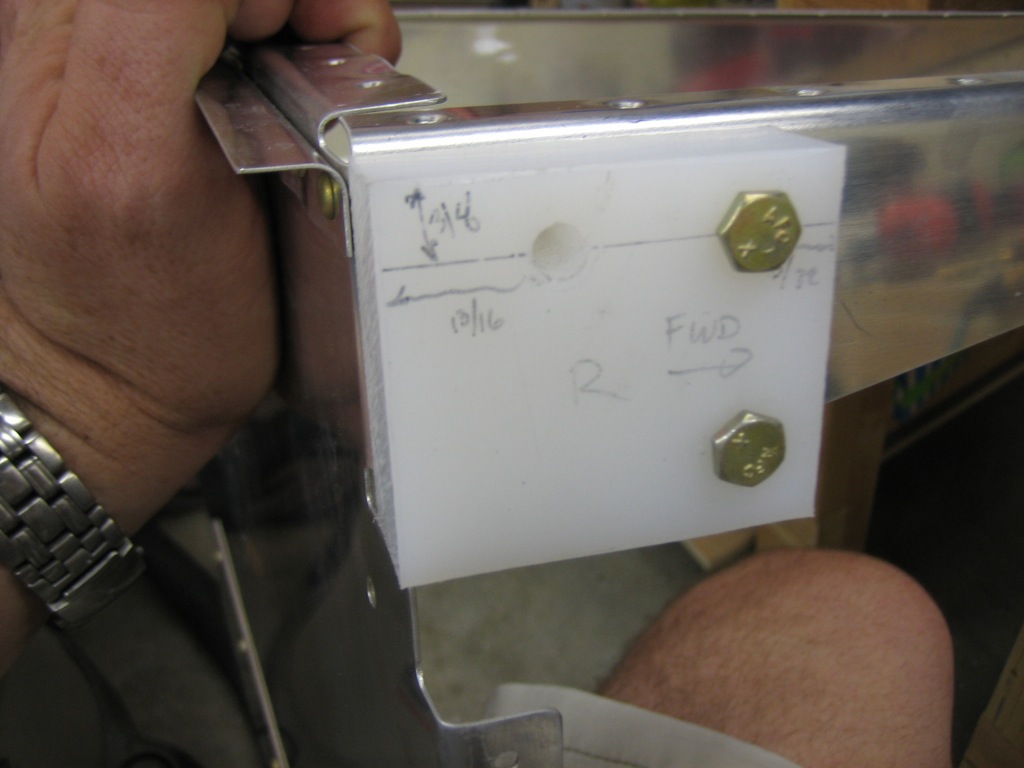

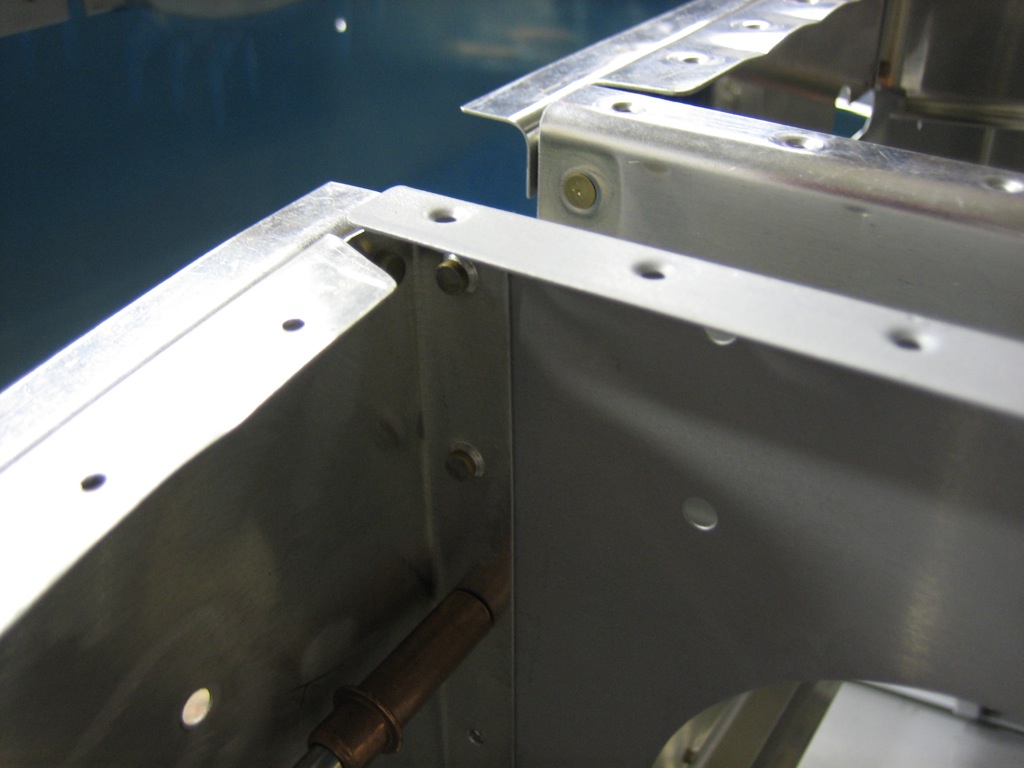

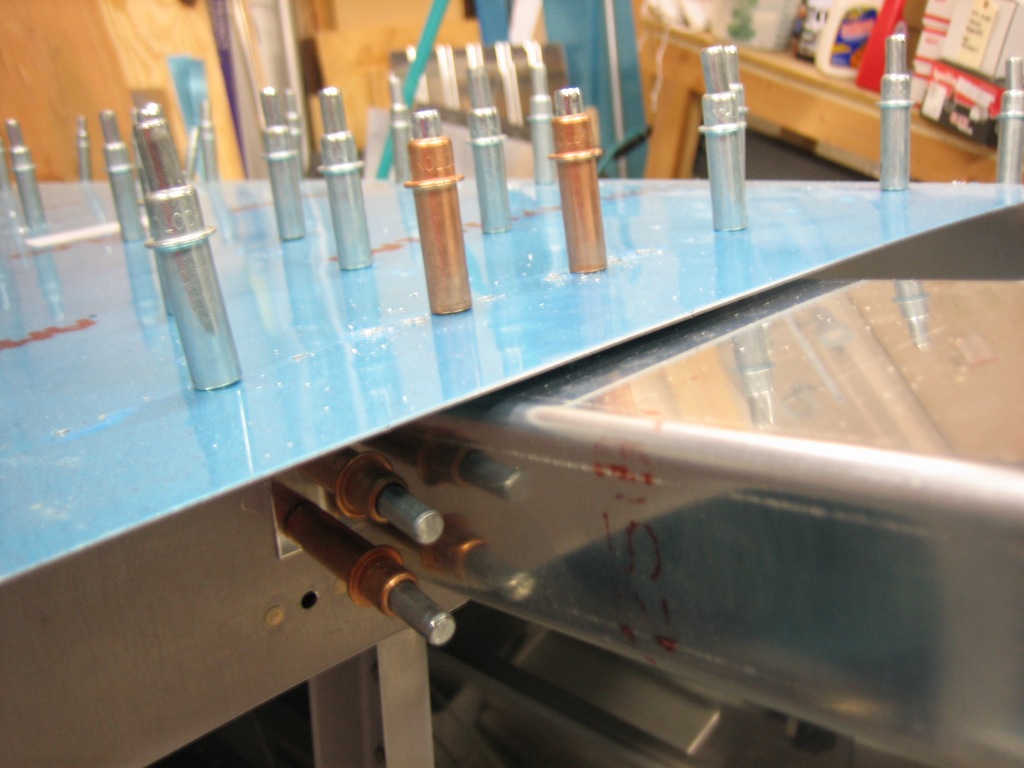

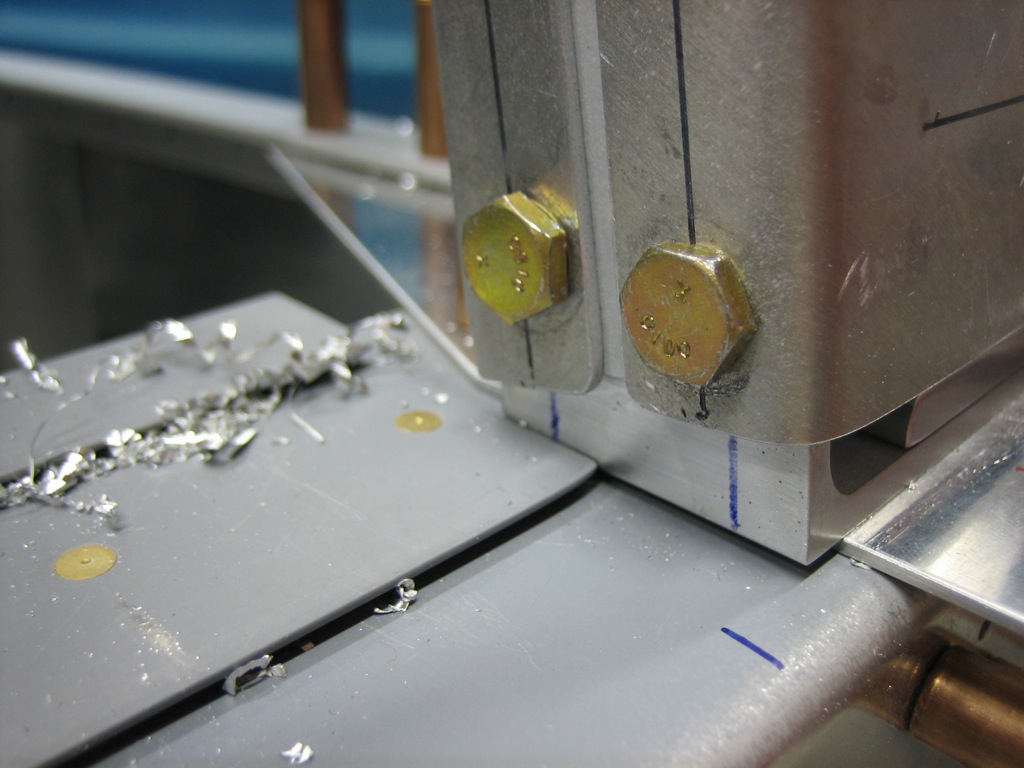

I clamped all of the canopy hinge block components together and drilled #12 holes through the forward fuselage channels.

After these were drilled, I removed the center subpanel and installed the C-617 blocks using bolts through the newly drilled holes and then match drilled the 1/4″ hole.

I spent the rest of the evening preparing another hose order for Bonaco. There will still be at least one more hose order after this containing the fuel lines from the servo to the spider and the oil lines from the accessory case to the oil cooler.

Worked on Canopy Hinges and Latch

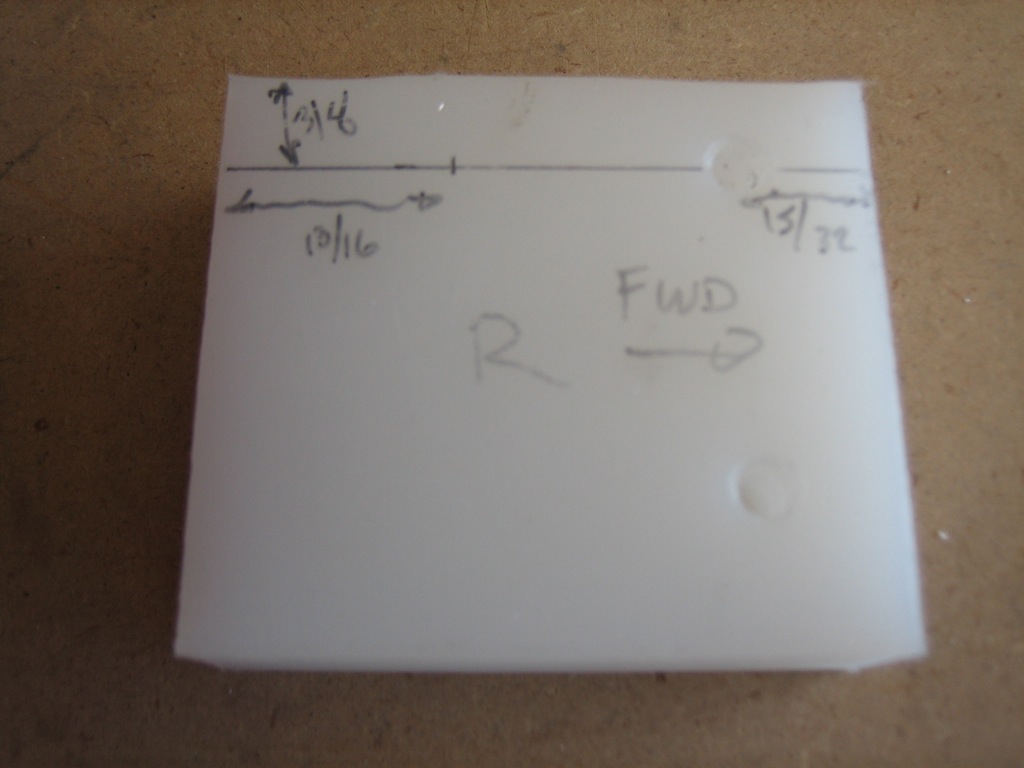

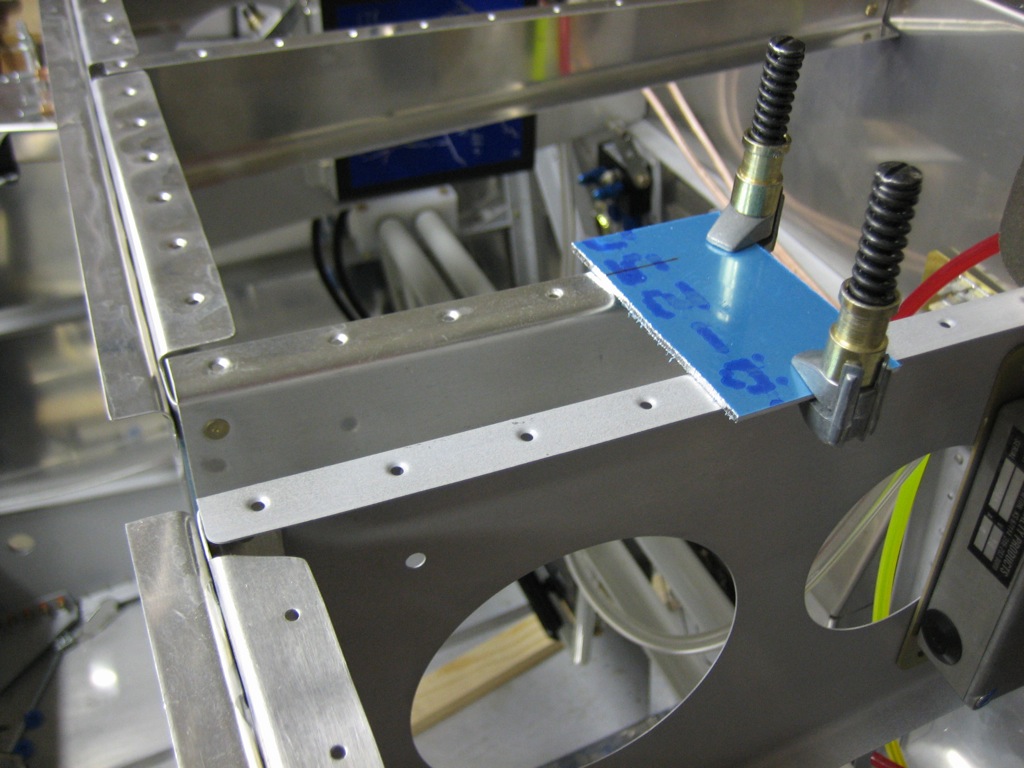

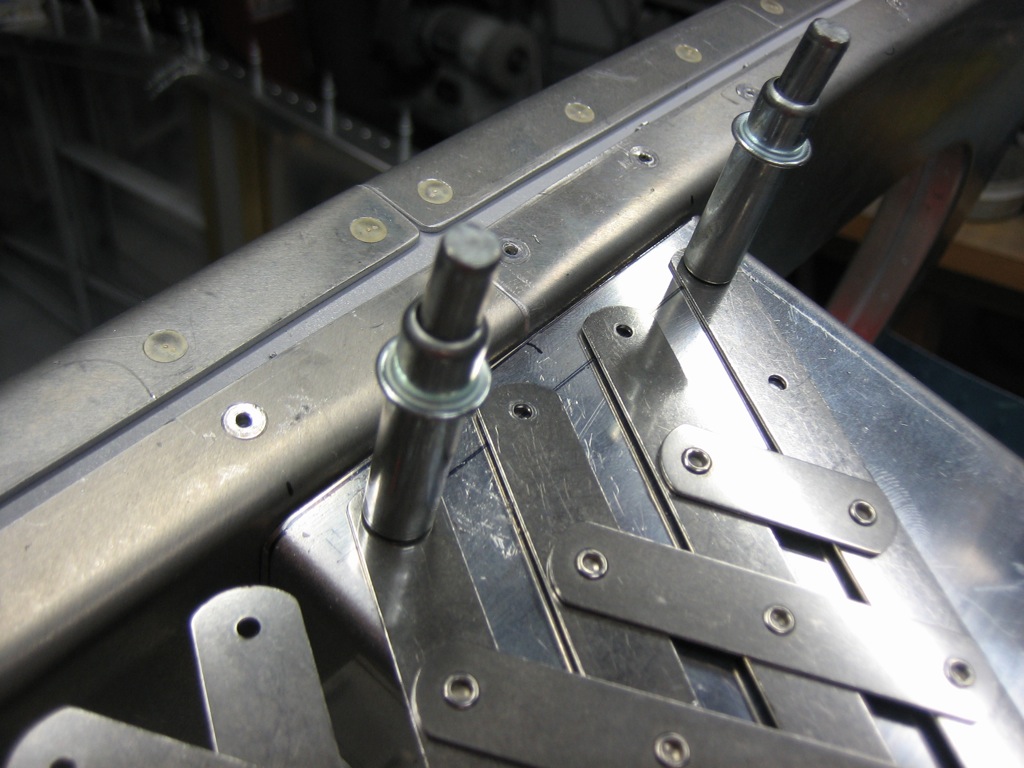

While I was working on the canopy hinge, my buddy Andre worked on the canopy latch. The torque tube is positioned and clamped in place.

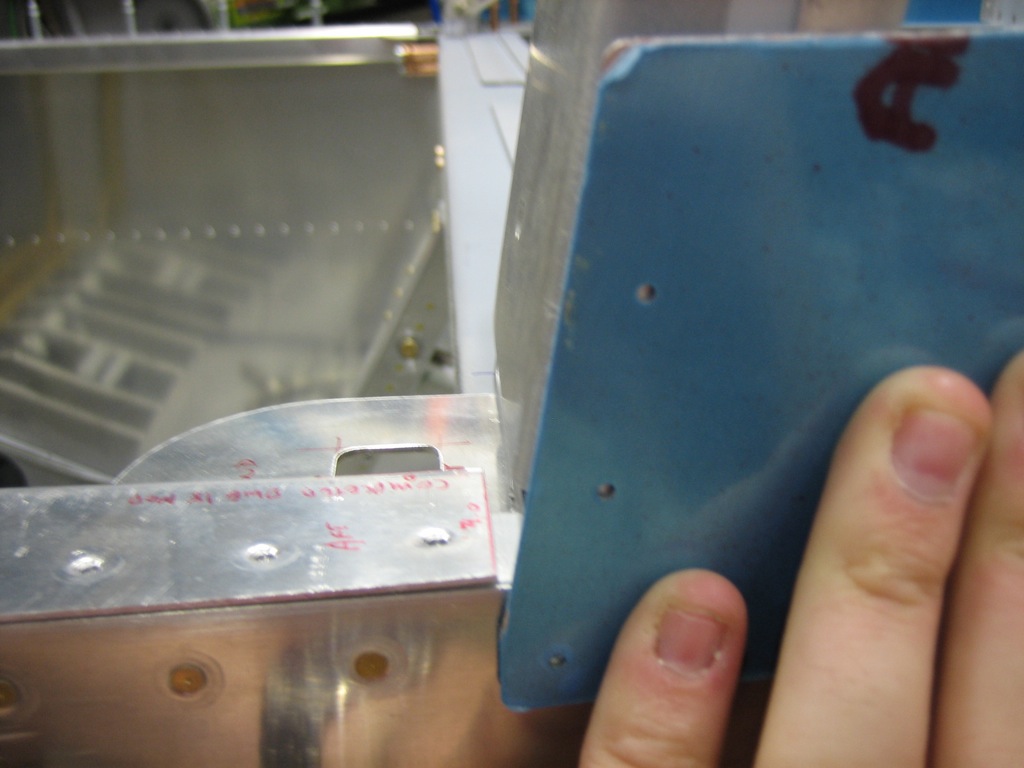

Here you can see that the finger on the end of the latch penetrates the hole in the seat back bulkhead. After ensuring everything was positioned properly, we marked the position of the holes in the bushing blocks with a #30 bit.

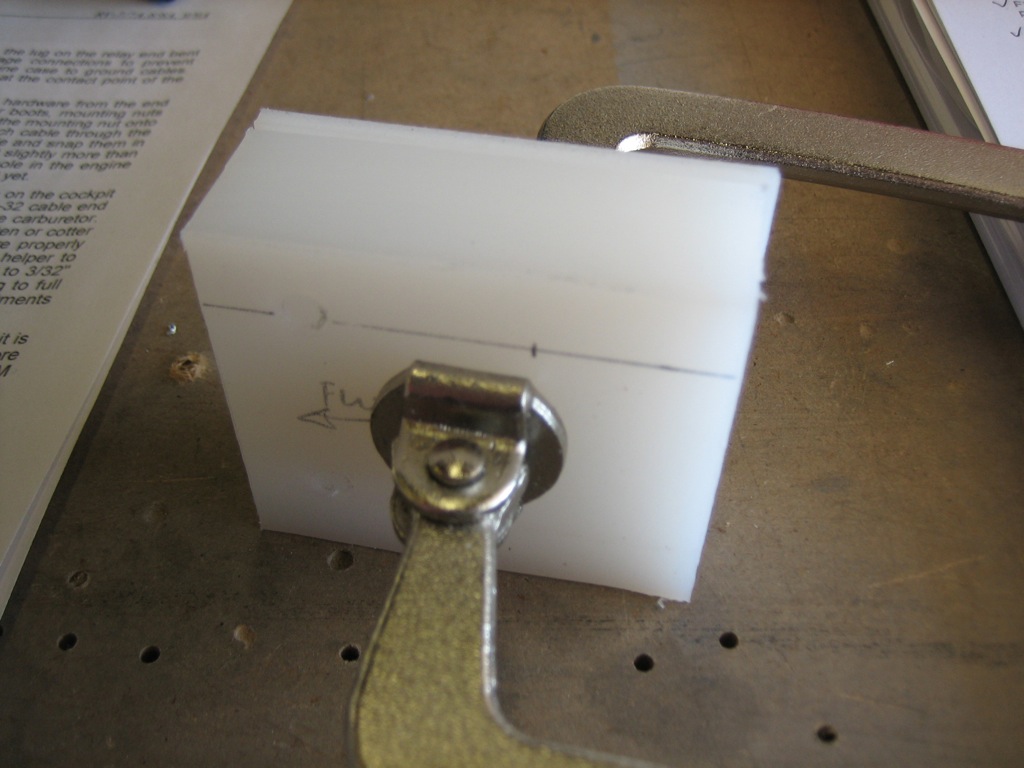

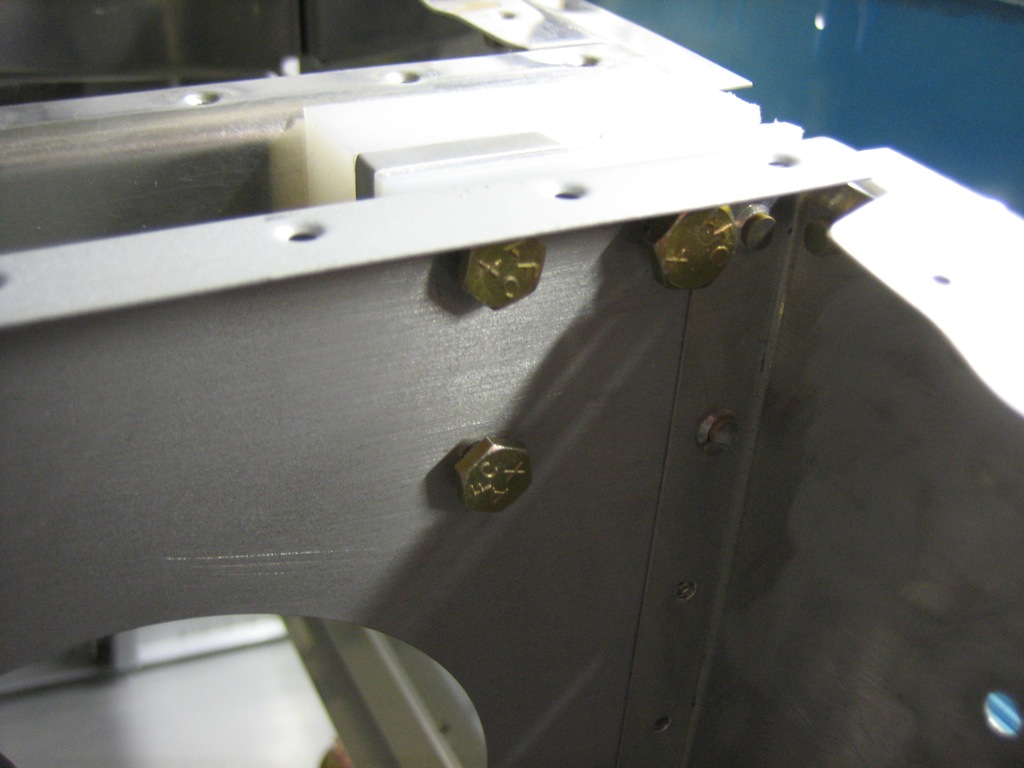

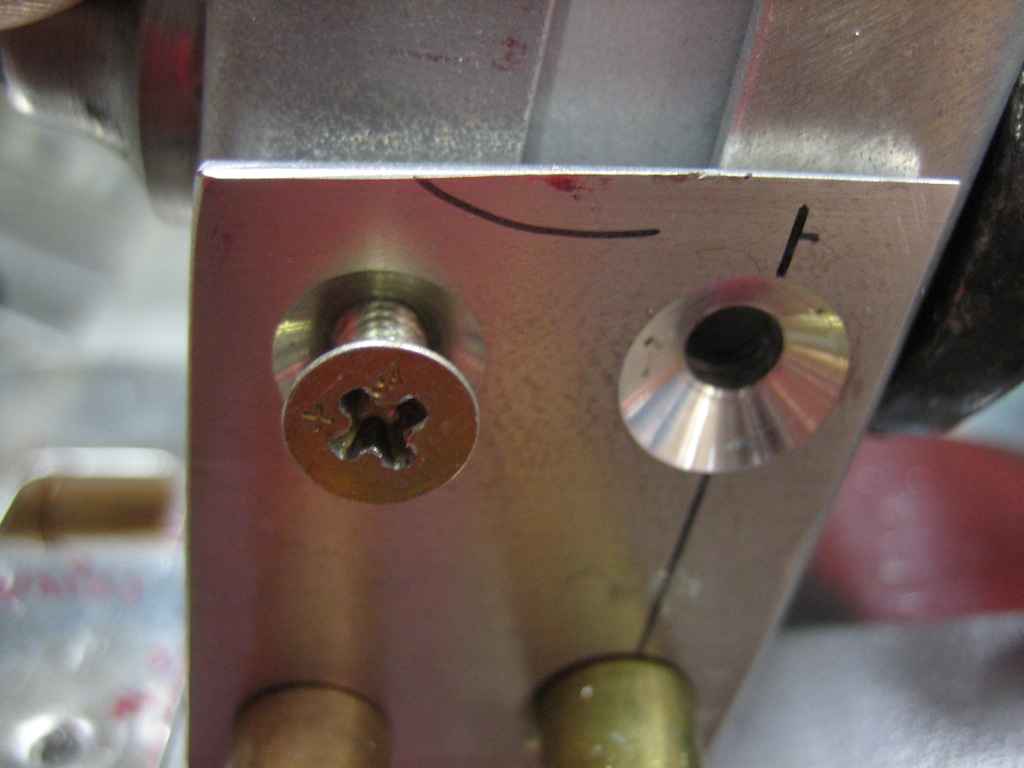

After match drilling the C-619 spacer (aluminum spacer between the plastic blocks), I reinstalled the center subpanel and used bolts placed loosely through the holes to keep everything aligned.

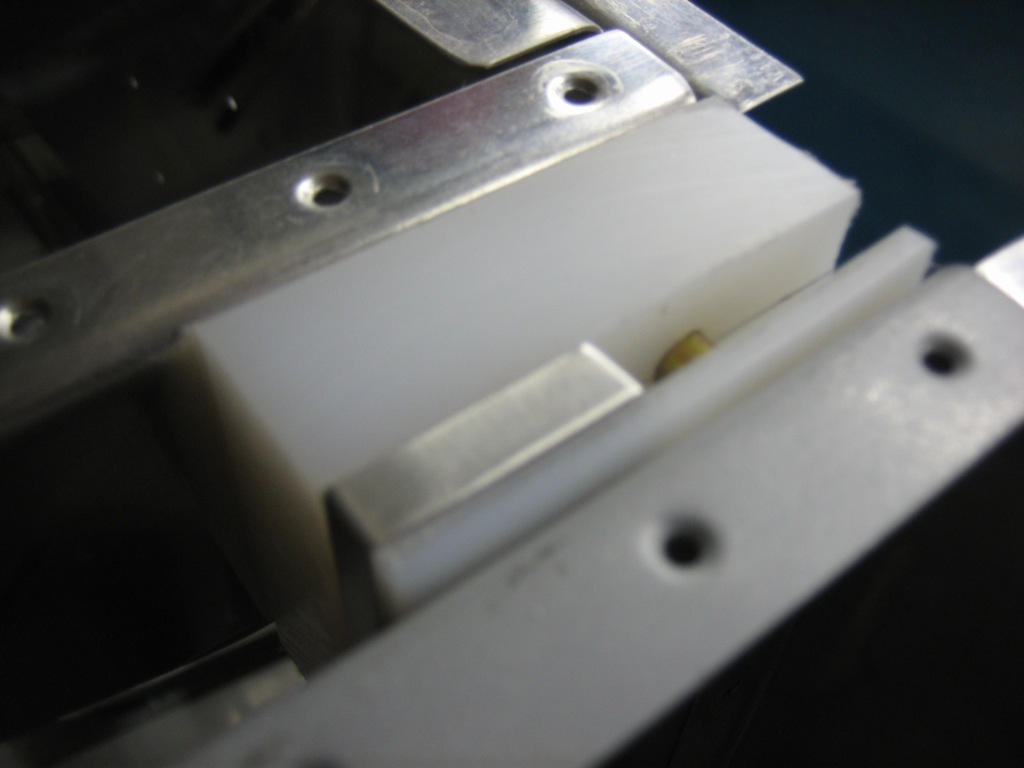

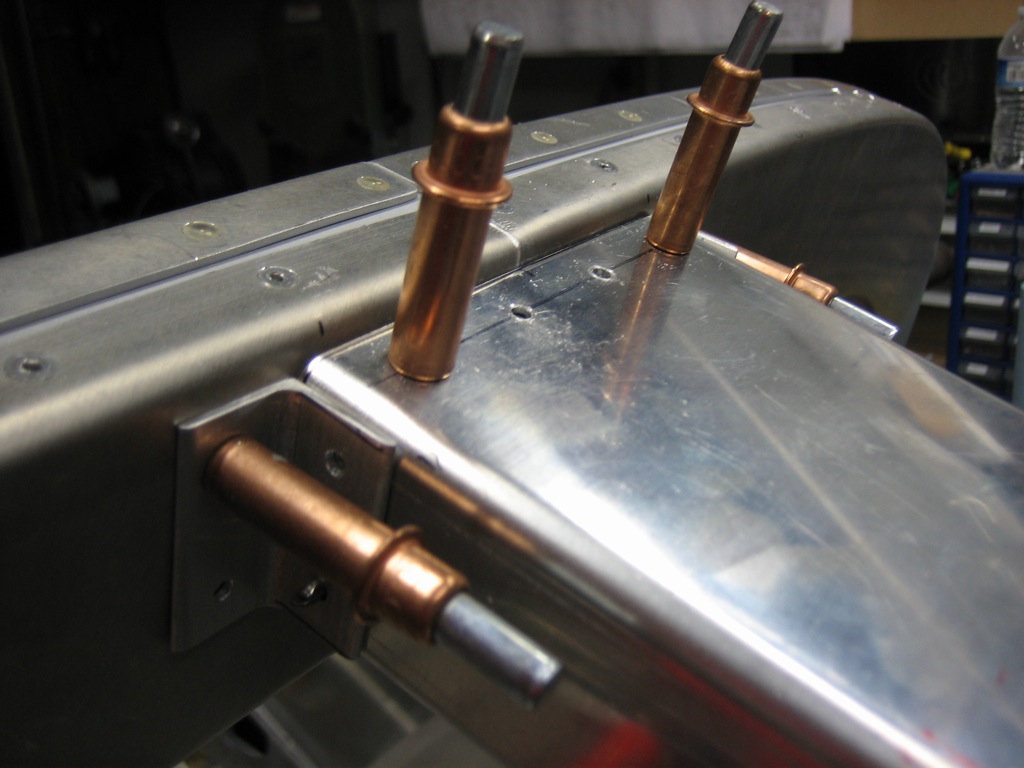

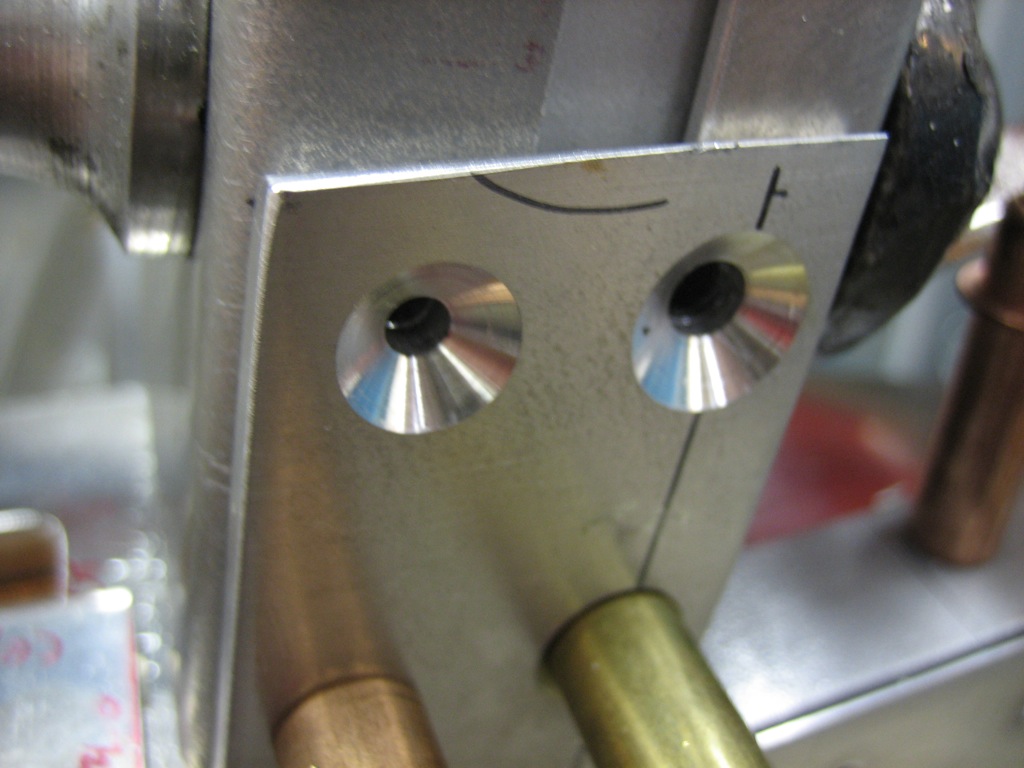

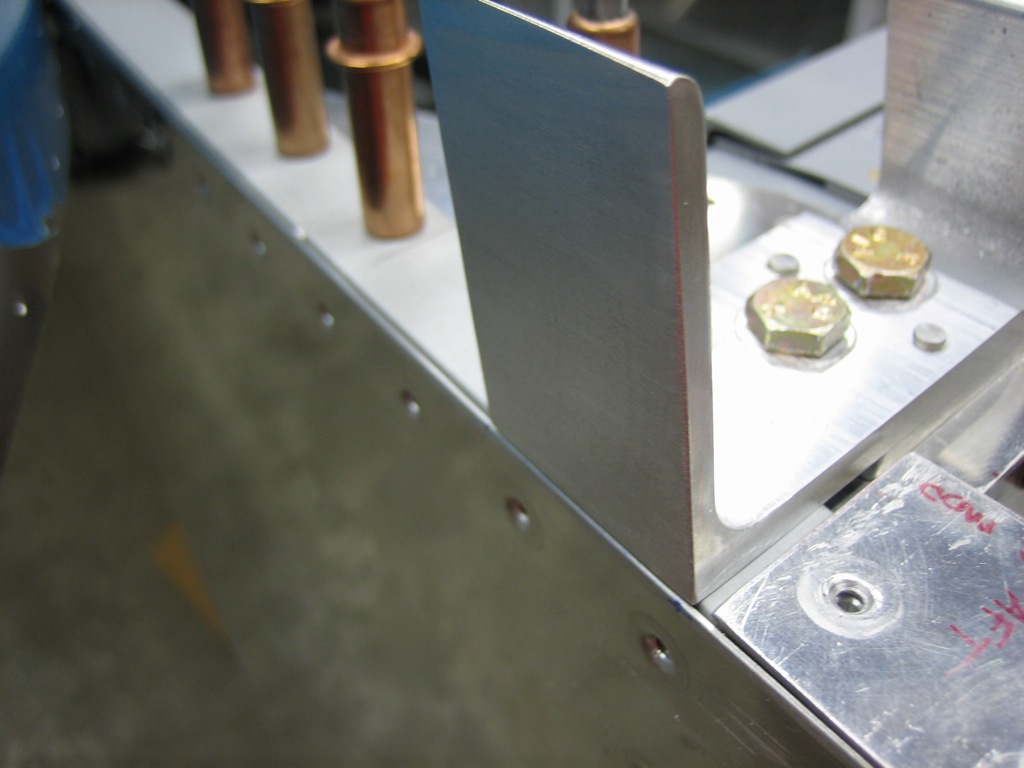

Here’s a closeup showing how the aluminum spacer is sandwiched between the two plastic blocks. The spacer is the exact width of the hinge bracket on the canopy.

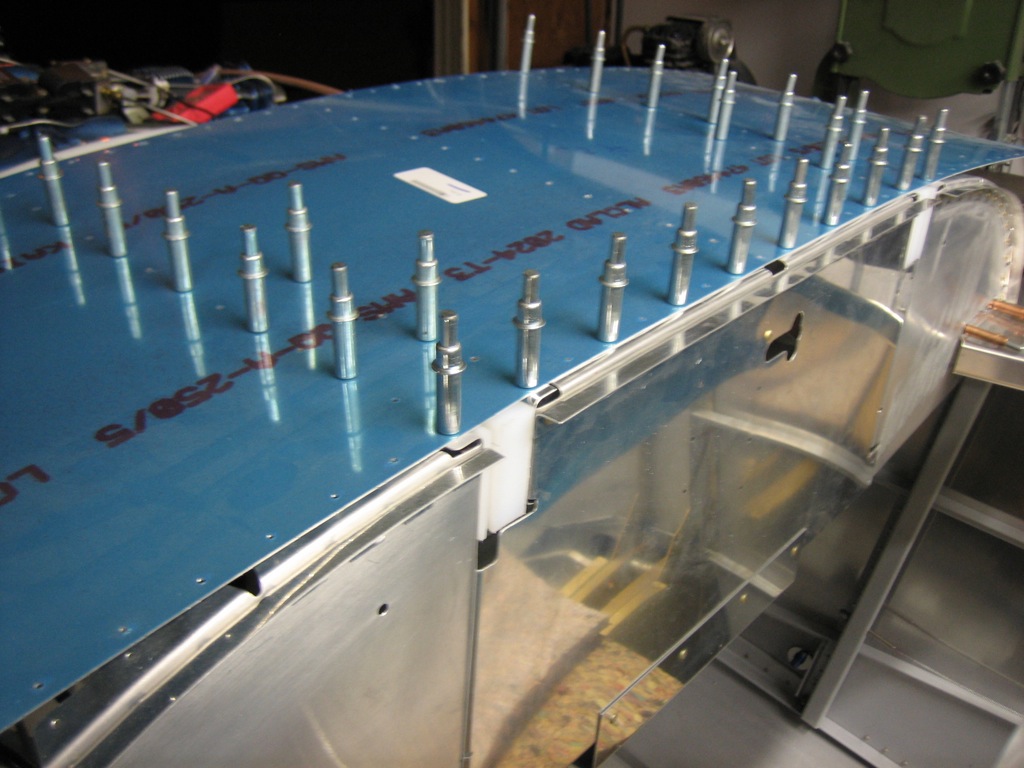

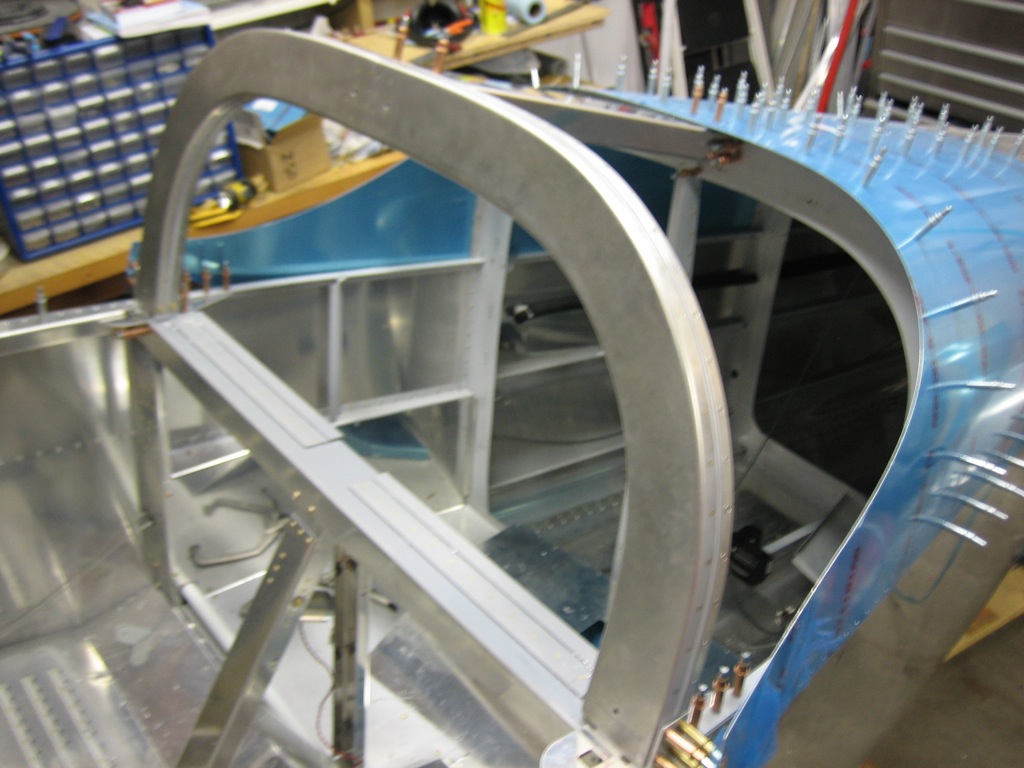

Finally, I reinstalled the top skin to pull everything into its final position.

Worked on Canopy Hinge Blocks

Started Canopy Hinge

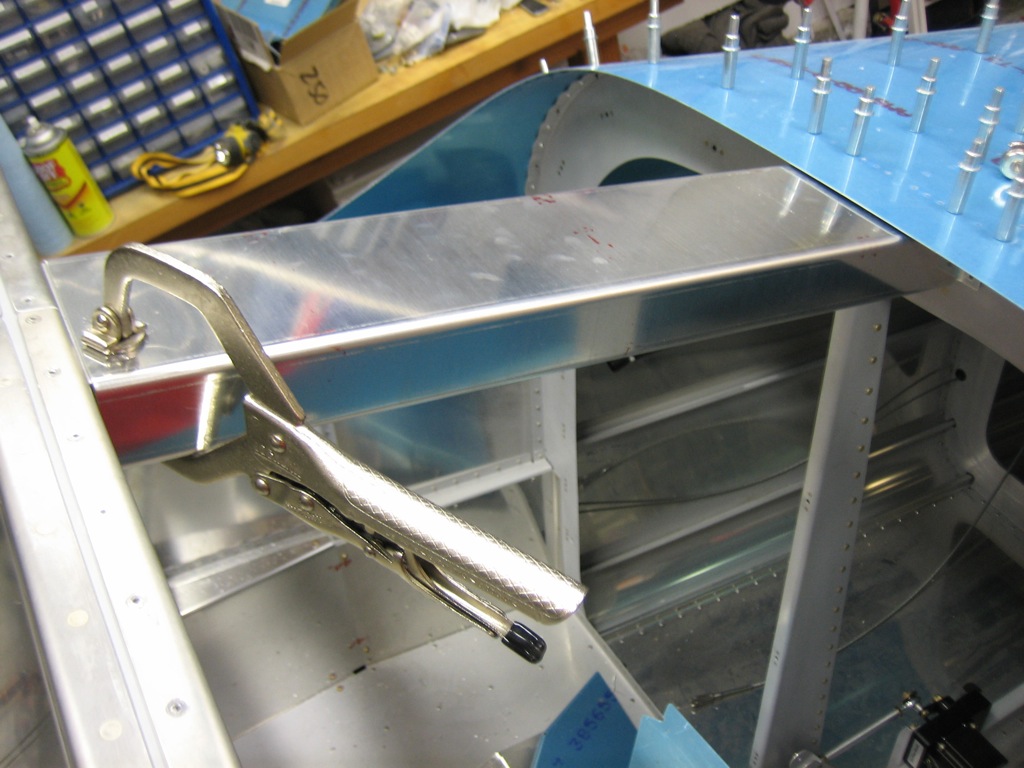

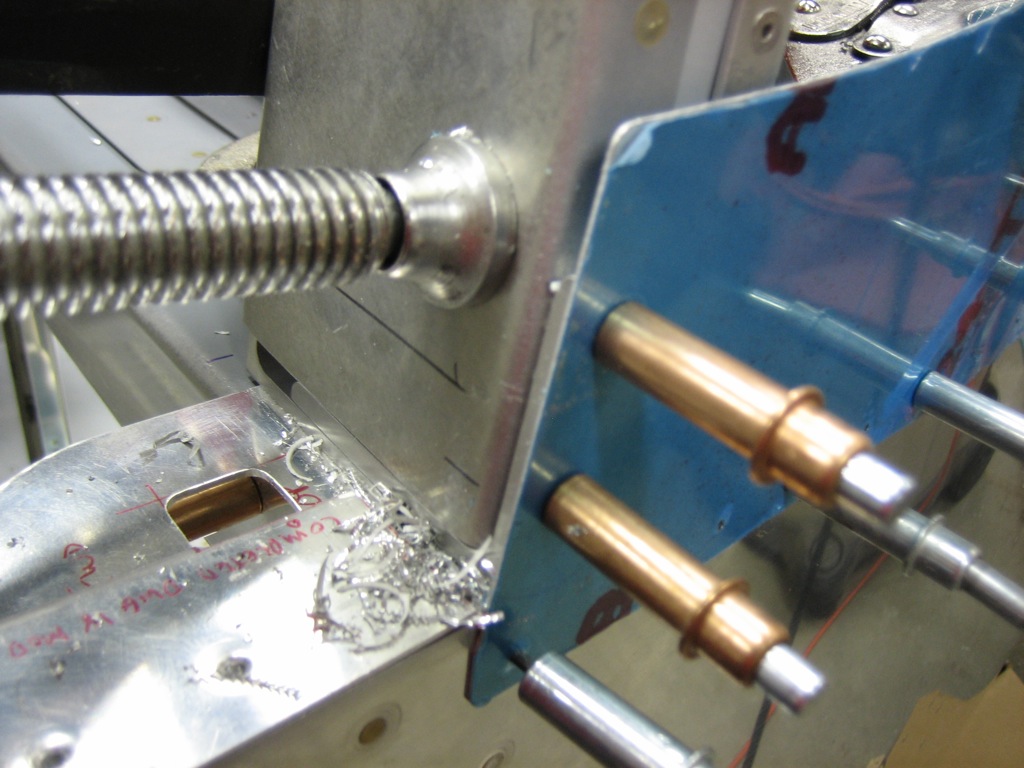

I started working on the canopy hinge mechanism tonight. First up is to rivet the outer subpanels to the forward ribs using the top two holes with flush rivets on the inside. This is so the hinge blocks can be mounted flush to the ribs.

I clamped a piece of scrap metal over the small inner riblets to align it with the outer forward ribs.

Toured NASA Dryden Flight Research Center and Edwards Air Force Base

I haven’t had a chance to work on the RV over the past few days, and today was no different, but at least I have a good excuse. I woke up quite early and flew our Cardinal down to Mojave, CA with a couple of friends. We arrived about 9 am and parked out in front of the Scaled Composites hangar. White Knight Two was out on the ramp when we arrived. The coordinator for our trip had arranged for a fleet of limos to drive us over to Edwards AFB, so we hopped in for the 20 minute drive over. We boarded what looked like a retired prison transport bus for the last part of the trip.

First stop was the NASA Dryden Flight Research Center. They have a nice museum with many of the supersonic and hypersonic aircraft on display as well as a number of other research aircraft. We got to tour the flightline and saw the apparatus that loads the space shuttle onto the back of the 747 for the trip to Florida when the shuttle lands at Edwards.

After lunch, we went to Edwards where we toured the base and then toured the flight line. They have an enormous number of aircraft there that they use for a wide variety of flight tests. We saw a huge number of F-16 and T-38 aircraft that they use for chase and flight currency. They also have a number of KC-135 and C-17 aircraft stationed there. We saw a B-1B on the flightline as well as a couple of F-22s and one F-35 Joint Strike Fighter. There are a number of other aircraft based there including the Predator, but we didn’t get to see them.

The dry lake bed is pretty amazing. 40 square miles of basically perfectly flat surface that’s harder than concrete. They’ve painted 18 runways out on the lake bed including one that’s 7 miles long. There’s also the world’s largest compass rose painted on the lake bed that is 1 mile in diameter.

Worked on Cabin Frame Channel

I primed the mating surfaces and riveted on the forward cabin frame channel attach angles.

I also countersunk the doubler and riveted it onto the channel using the forward holes. The aft holes will tie these pieces to the top skin and F-706 bulkhead.

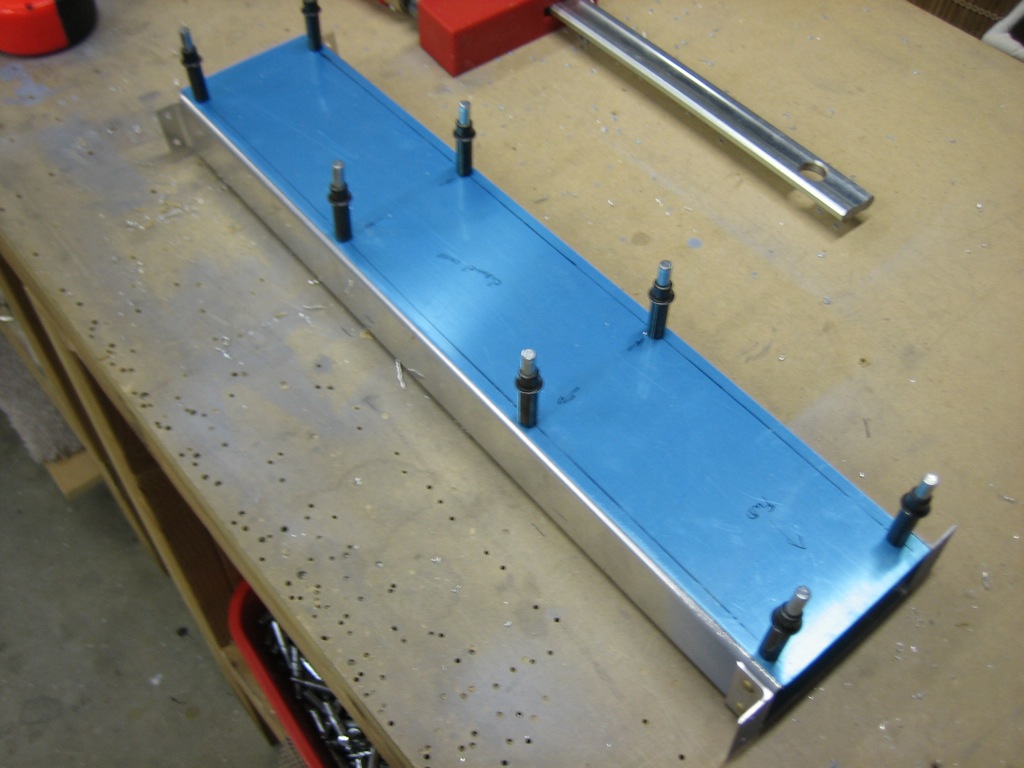

I cut out the cover that I’m fabricating for the channel and drilled a series of holes with a #19 bit for #8 screws.

I riveted on some countersunk nutplates and screwed the channel cover on. Here it is reinstalled in the plane. I’m going to install a light here that can be used to illuminate the interior both in flight as well as during loading/unloading.

Finished Attaching Cabin Frame

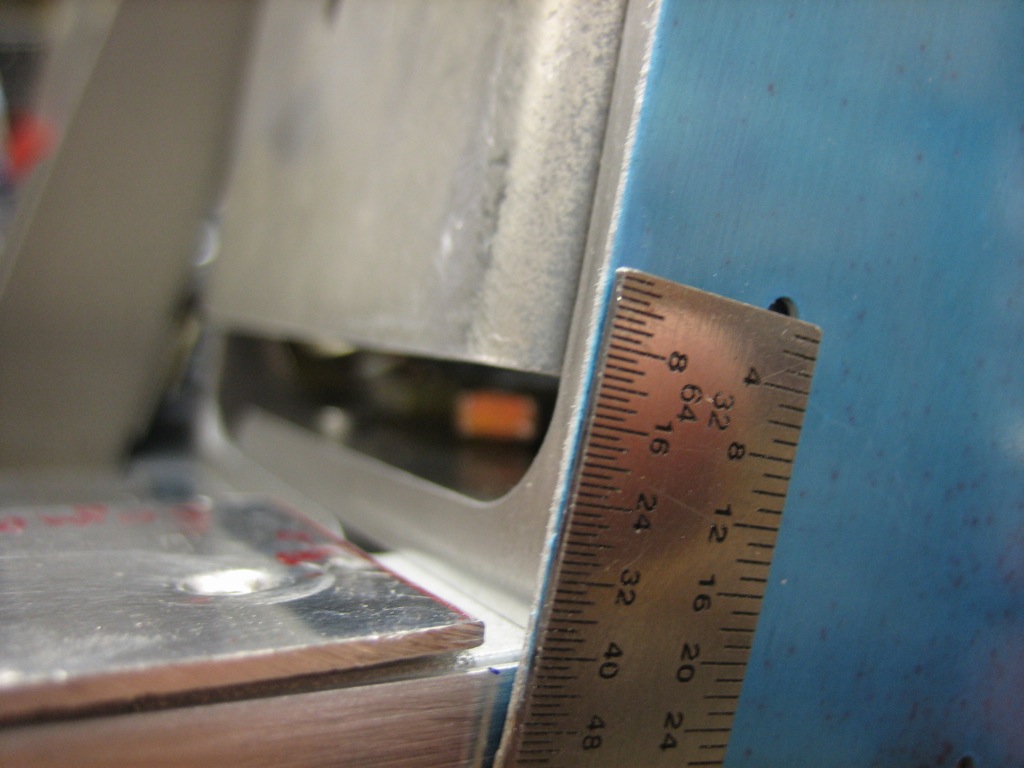

I ended up positioning the cabin frame exactly where the plans specify, 17 7/8″ up from the aft canopy decks. After clamping everything securely in position and double checking the measurements, I started drilling. First up is to drill the aft edge of the channel to the top skin and F-706 bulkhead as well as to drill the channel flanges to the bulkhead.

Next up is to layout the four holes that attach the channel to the cabin frame. I drilled these to #40 first using the fan and then opened them up to #30.

I also drilled the side angles to the channel and cabin frame.

I used a couple of c-clamps to squeeze down the cabin frame where it had flared out near the bottom and was thicker than 1.5″. I then drilled the forward holes through the side skins and through the attach angles and cabin frame. These were initially drilled to #30 so that they could be clecoed.

I then laid out and drilled the aft holes. These are drilled perpendicular to the cabin frame and then countersunk for a #10 screw. The countersink is asymmetric because the attach angle curves to follow the longeron. The countersink needs to be deep enough so that the screw is below the surface of the attach angle since the skin lays over the top of this screw.

The forward holes are then countersunk for a #8 dimple. Notice that these holes are drilled perpendicular to the face of the attach angle, not perpendicular to the cabin frame. This is because a screw will screw in here and it needs to be flush with the skin. The aft holes need to be perpendicular to the cabin frame because there will be a nut installed on the inside and it needs to be flush with the inside face of the cabin frame.

After countersinking the forward holes, I opened them up to #29 and then tapped them with an 8-32 tap for a #8 screw.

Finally, I drilled the inner holes for AN3 bolts and installed some scrap AN3-5 bolts.

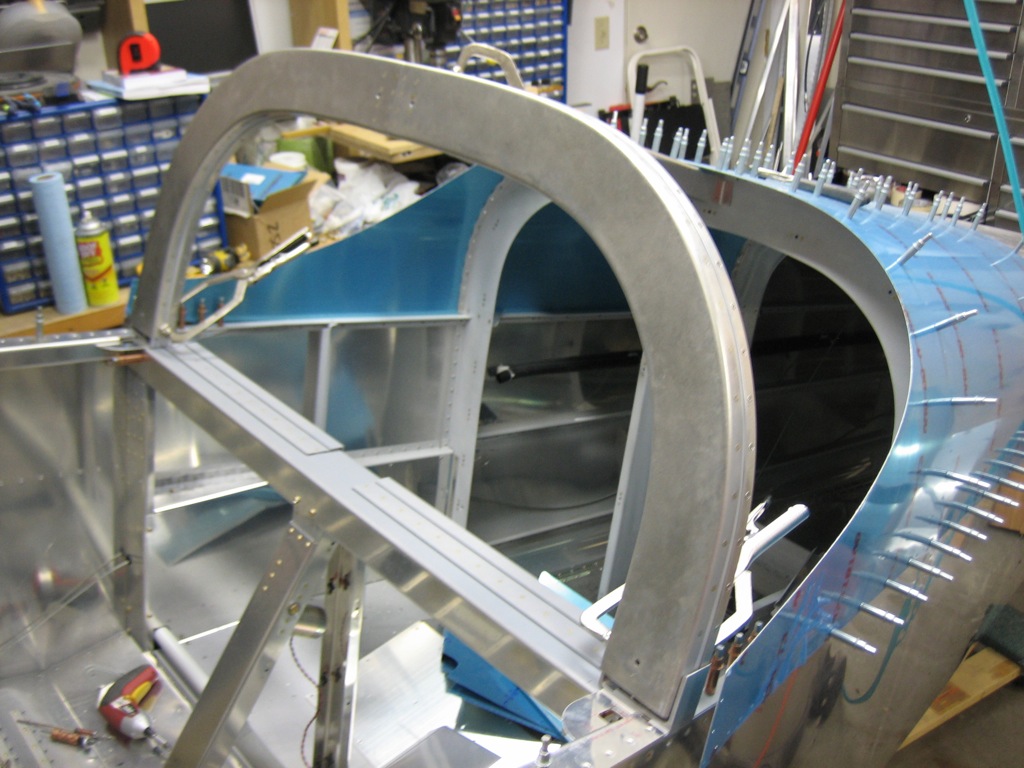

Here’s the whole cabin frame with all attachment points complete.

Lowered Cabin Frame

I had the cabin frame clamped 1/4″ above the location specified in the plans. I looked over the canopy plans as well as all of the fastener positions. This is the only issue I ran into. The lower #8 screw through the aft top skin would penetrate the cabin frame only 3/16″ above the lower edge. Since this hole needs to be drilled out to #29 and then tapped for a #8 screw, I didn’t think this was enough. I couldn’t lower the cabin frame much without the outer edges running into the inner radiuses of the attach angles. I didn’t get a picture of it, but I made a relief cut and radiused the edge to allow the cabin frame to drop down.

Here’s the cabin frame dropped to the height specified in the plans. There’s now approximately 7/16″ edge distance on this hole which would be more than plenty. I’m probably going to try and move the canopy up to the minimum edge distance for this hole to get as much headroom as possible. A #29 hole is 0.136″ diameter. 1.5D edge distance would require 0.204 edge distance which is just over 3/16″. If I increase that to 1/4″ to get a little more than minimum, then I’ll end up with a cabin frame about 3/16″ above normal.

Finished Cabin Frame Attach Angles

I finished trimming the cabin frame attach angles so that they’re flush with the sides of the fuselage. I alternated between using the vixen file and the disc sander, then finished up with the scotchbrite wheel.

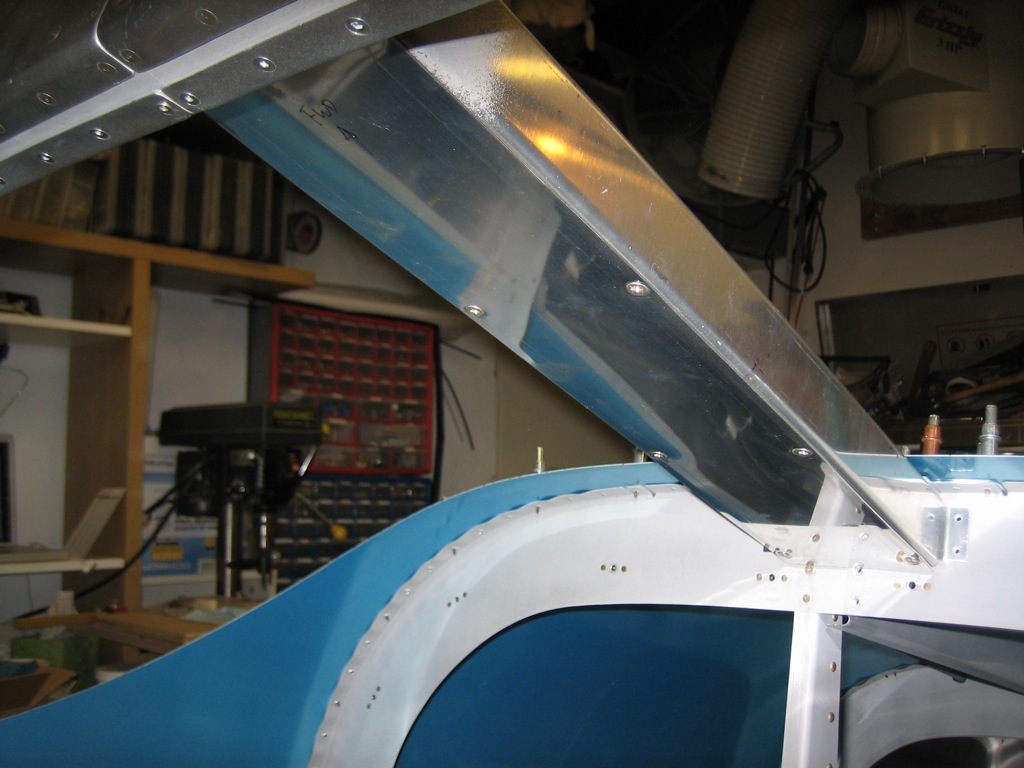

Here you can see how the aft top skin lays flush against the side of the angle.

Here’s the cabin frame clamped as low as it can currently go. It’s still about 3/16″ of an inch high right now, but I actually want it to end up a little high so I can get more headroom. One of the engineers at Van’s said the cabin frame could be moved up at least 1/4″ without any problems. I want to double check this before permanently mounting the cabin frame though.

Here you can see that the side skin is perfectly aligned with the cabin frame (both angle and longitudinal position).

I also installed the cabin frame brace to correctly position the cabin frame. It’s clecoed in the back, but only clamped in the front. I don’t want to drill this until I’m sure of the position.