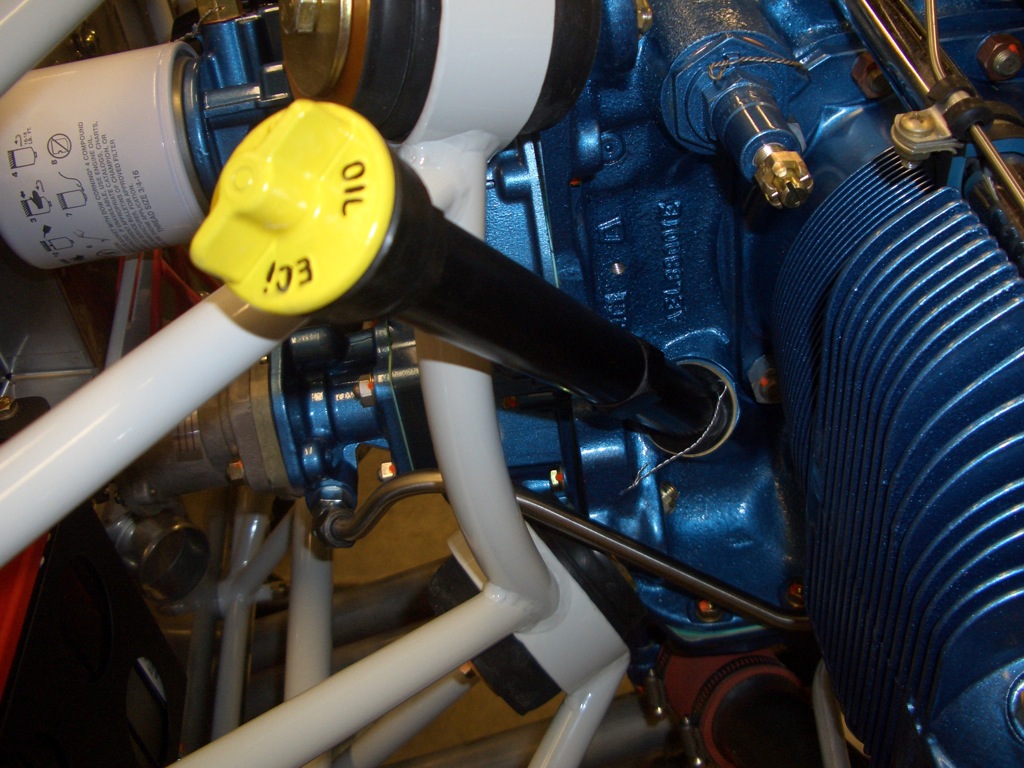

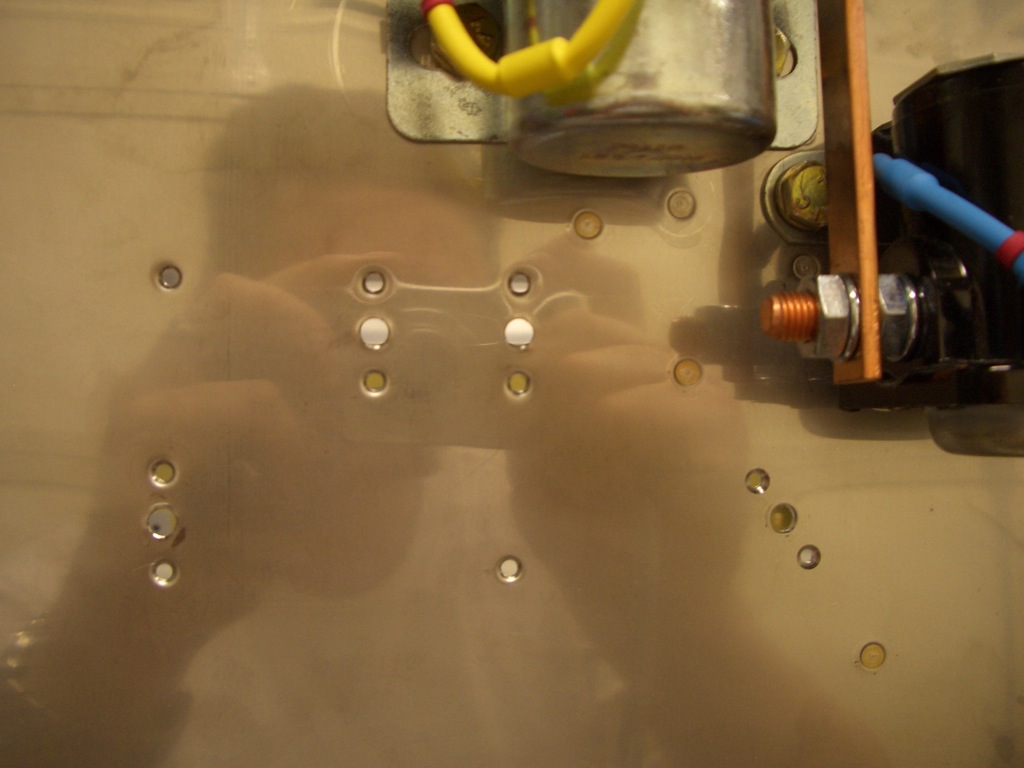

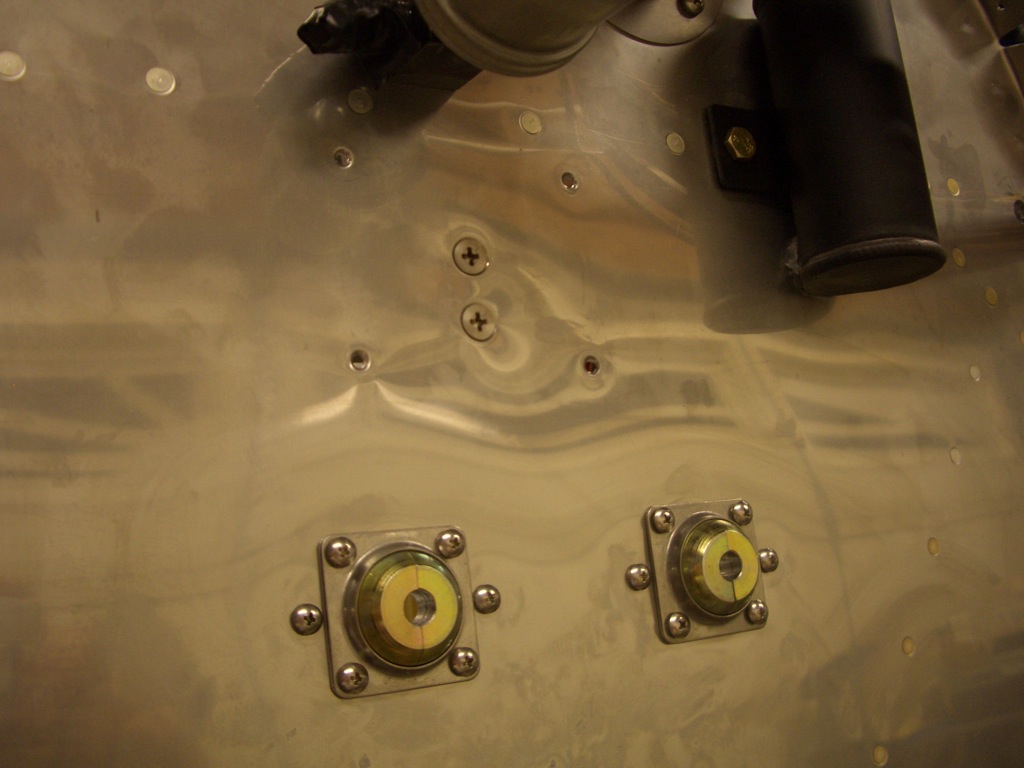

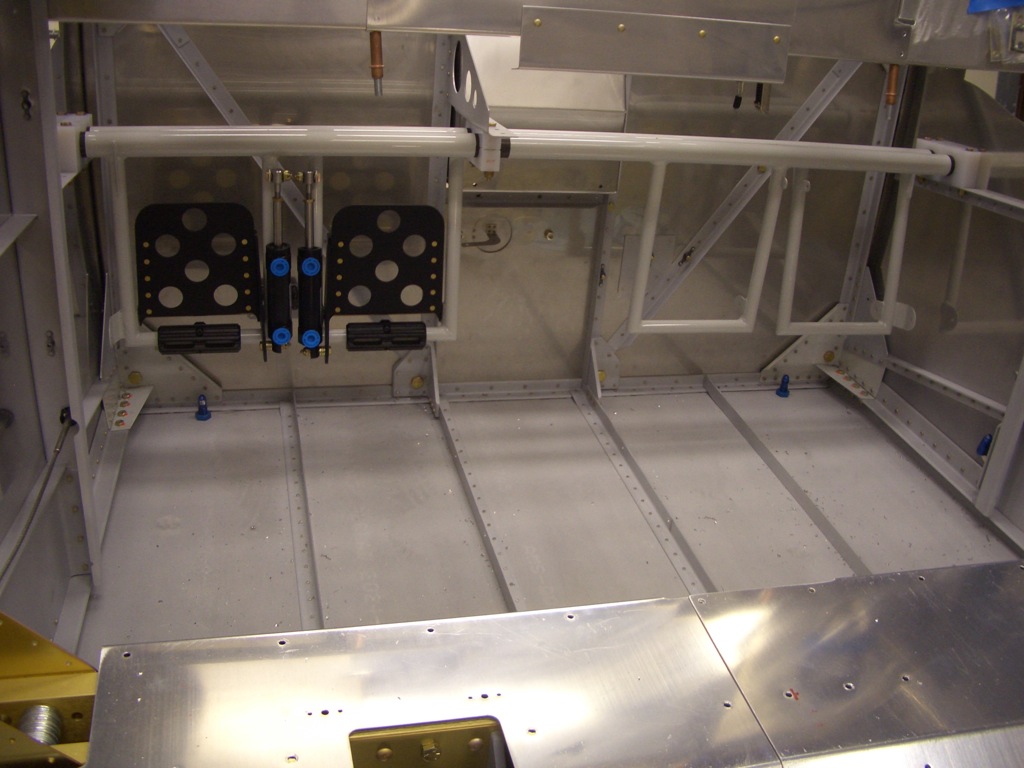

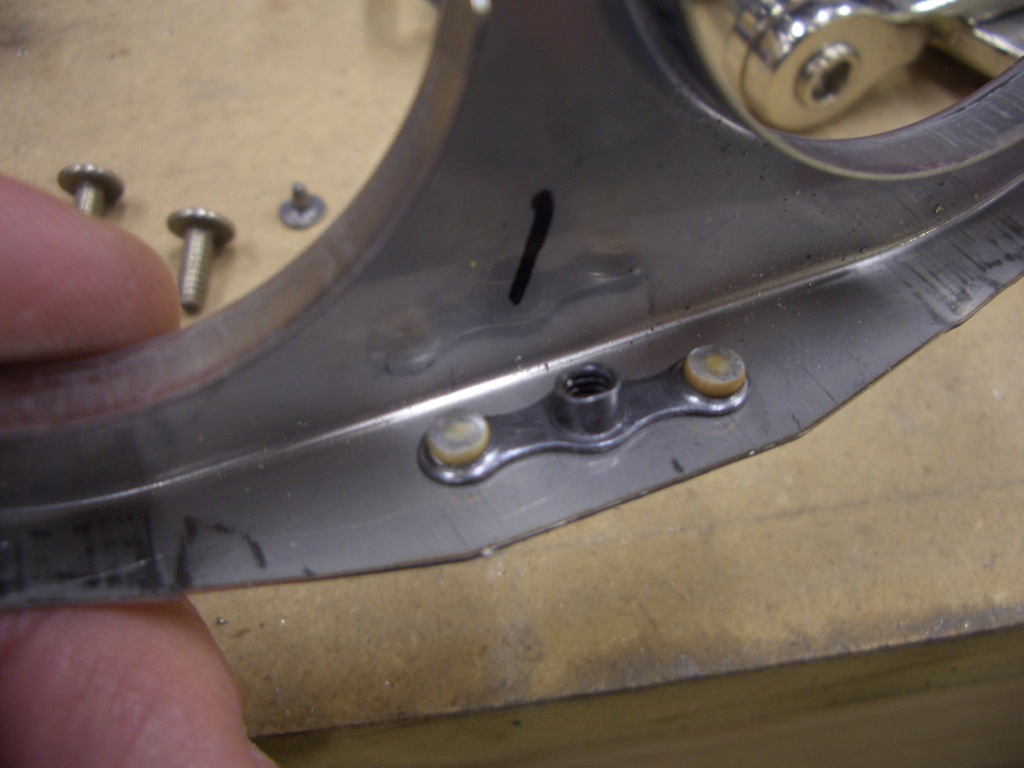

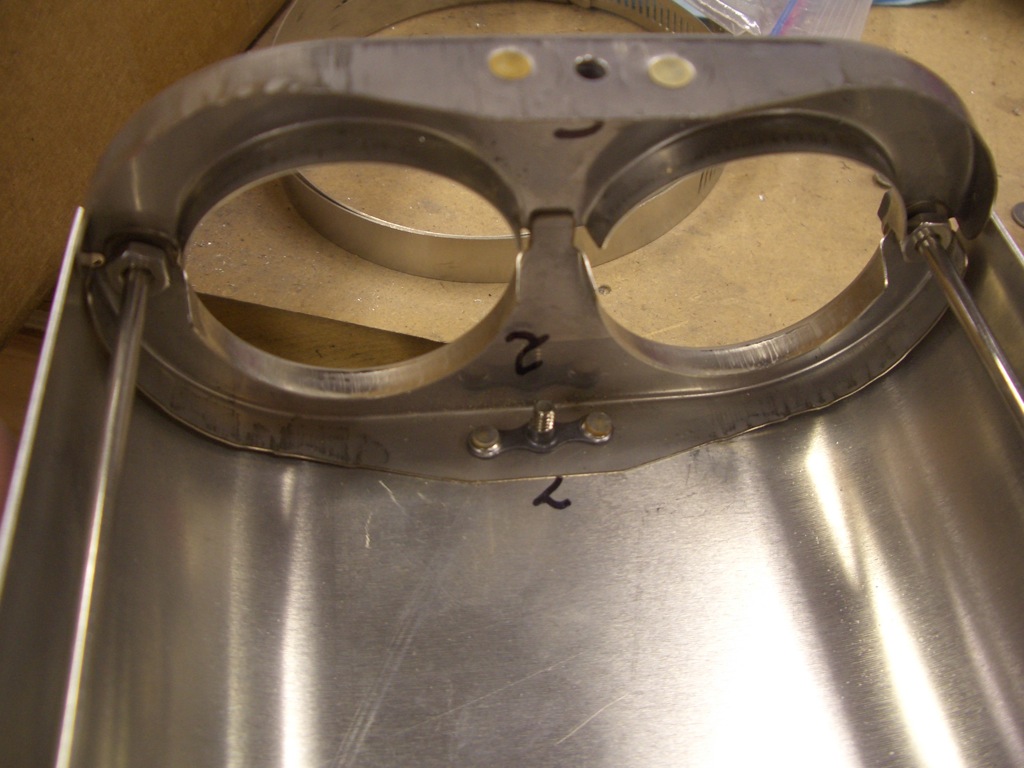

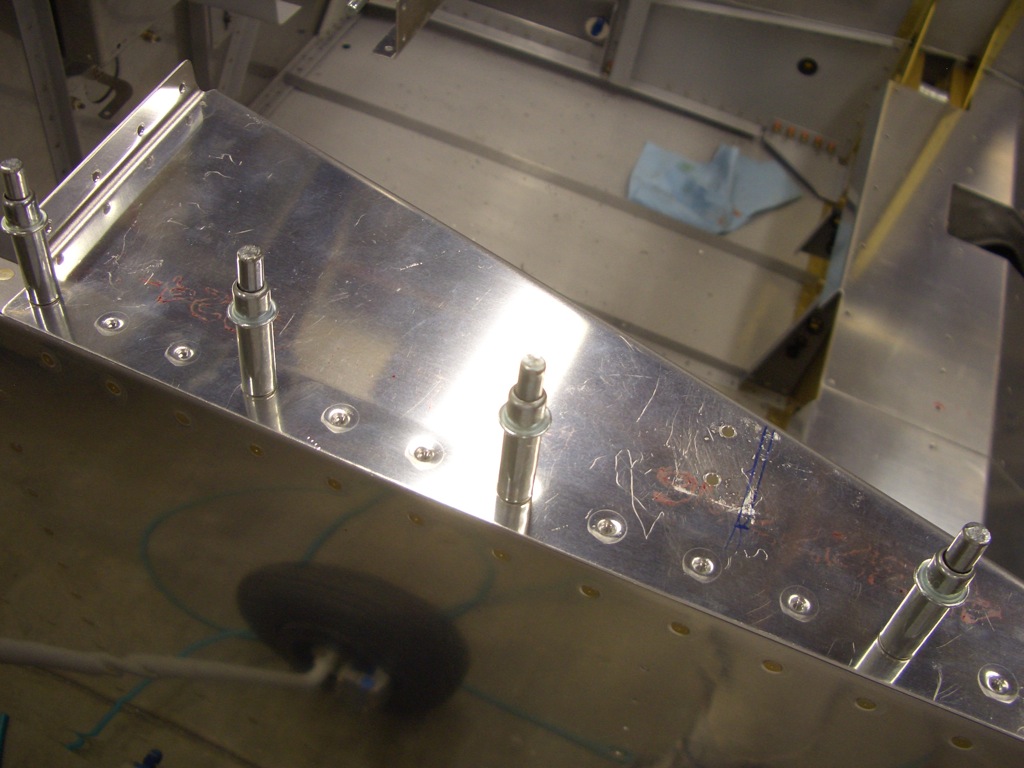

My buddy Andre came over today. We set the goal of hanging the engine by the end of the day. There were still a bunch of things that needed to be done to the firewall before we could do that though. First up was to drill the firewall for the ground block. Here is the back side of the firewall showing the “forest of tabs” for grounding all of the items in the plane at the same point. This helps to reduce (if not eliminate) sources of electrical noise in the aircraft.

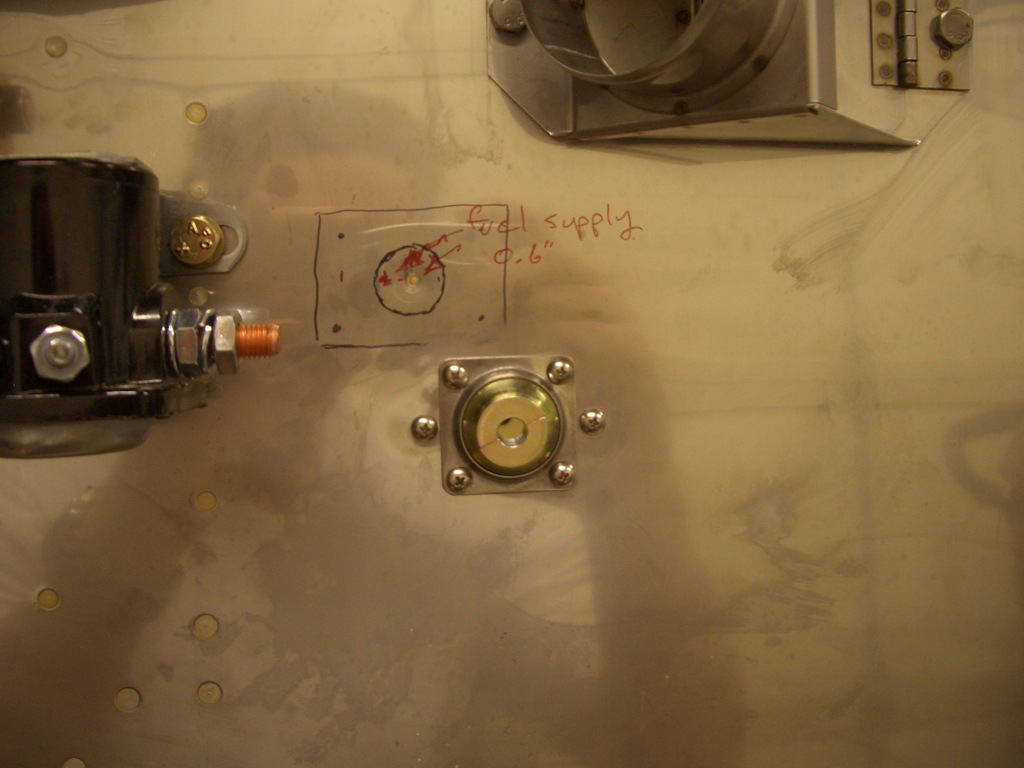

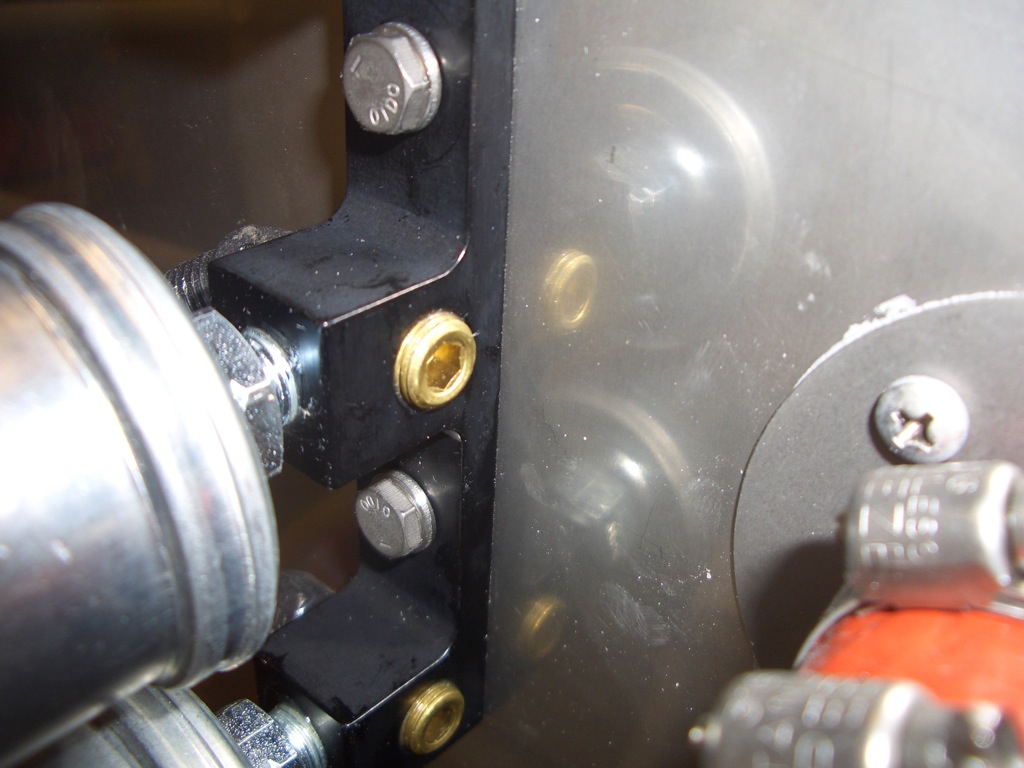

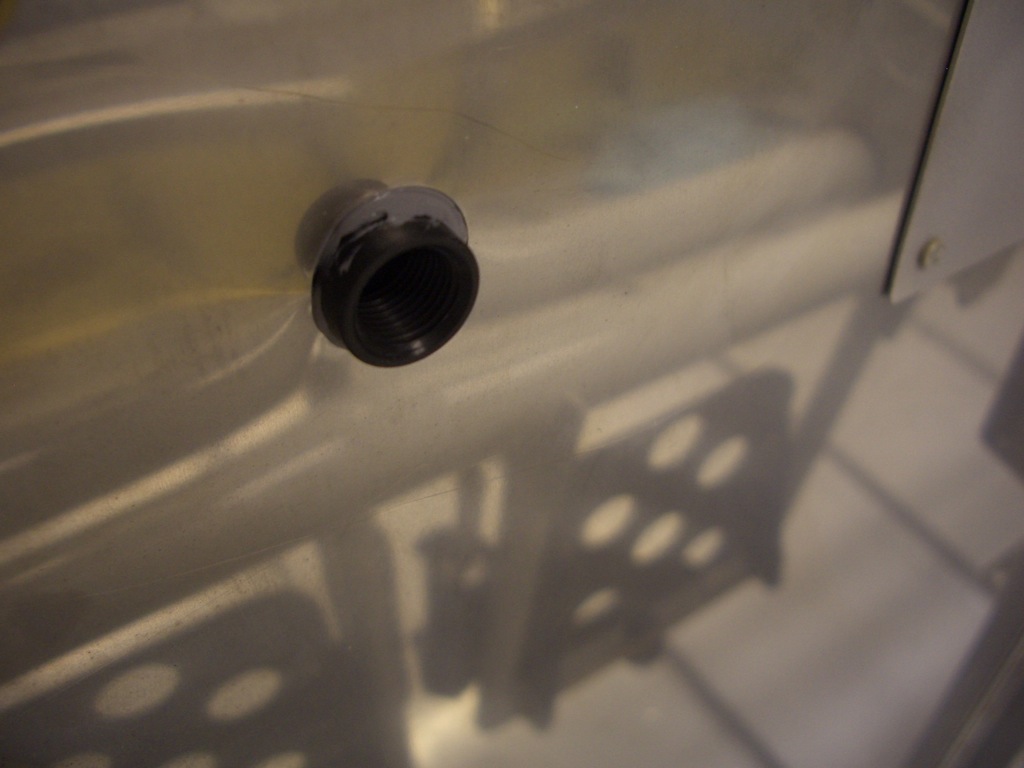

Here is the forward side showing where the mounting bolt is relative to the battery. I positioned it high enough that I can remove the battery without hitting the bolt.

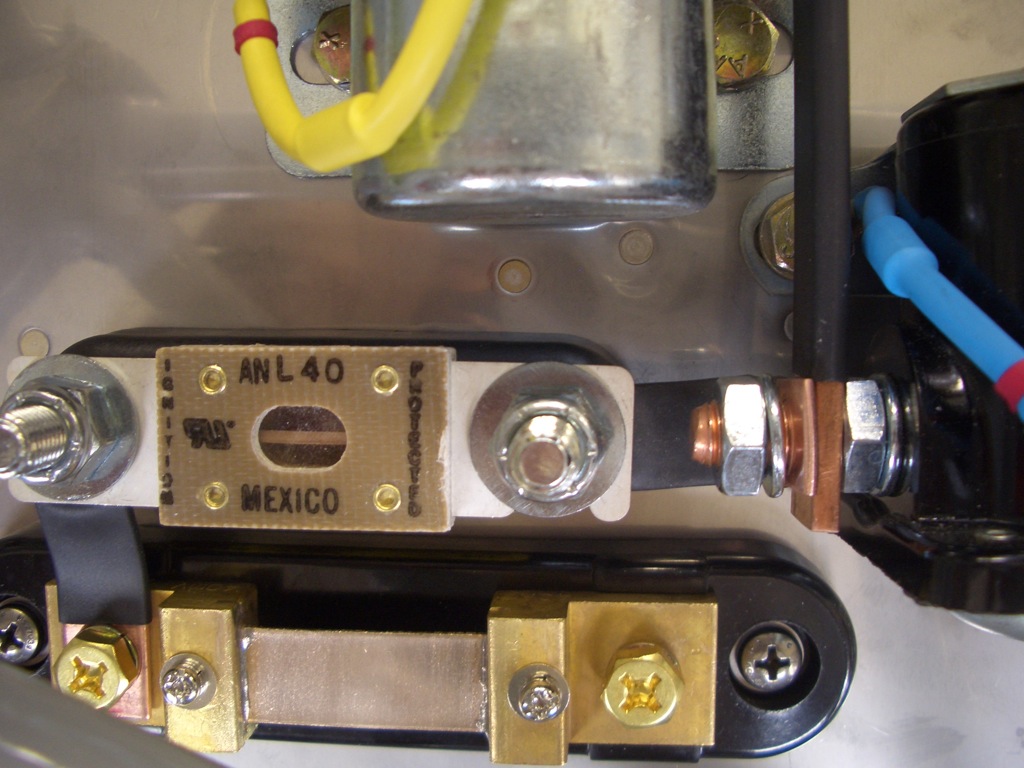

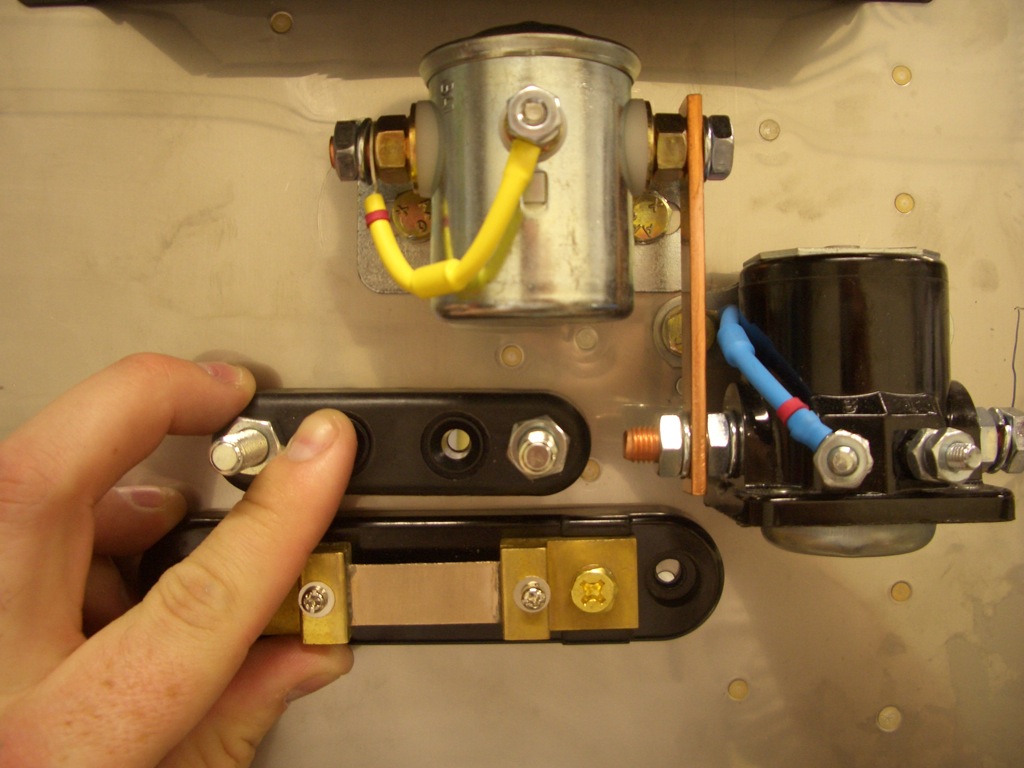

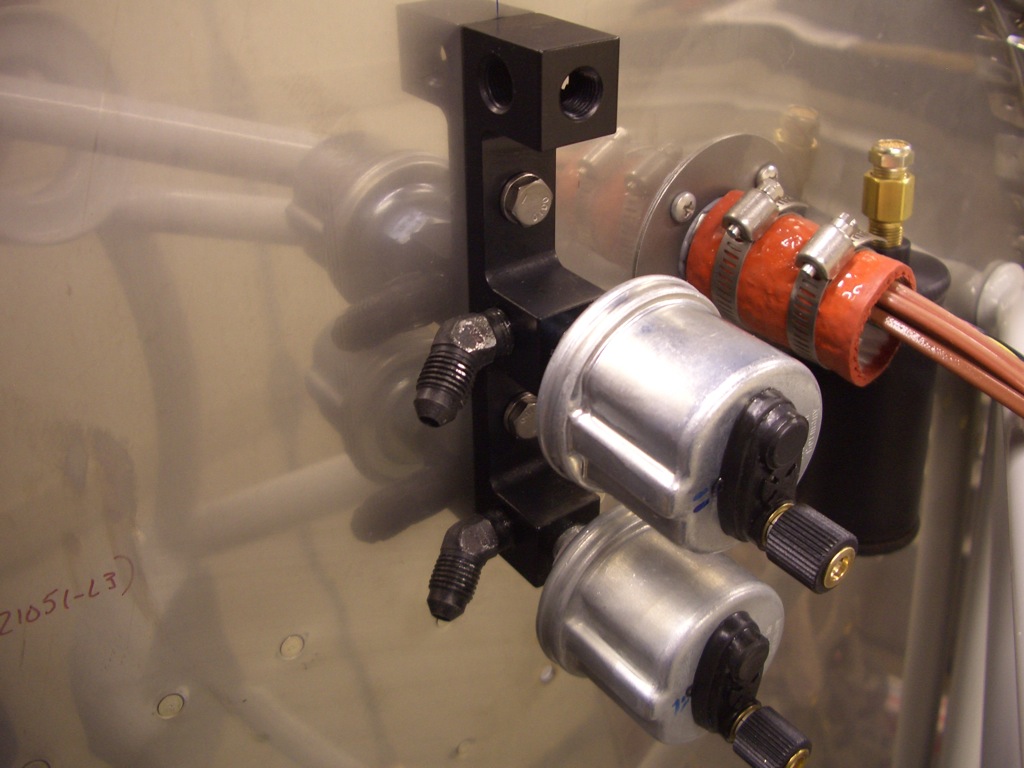

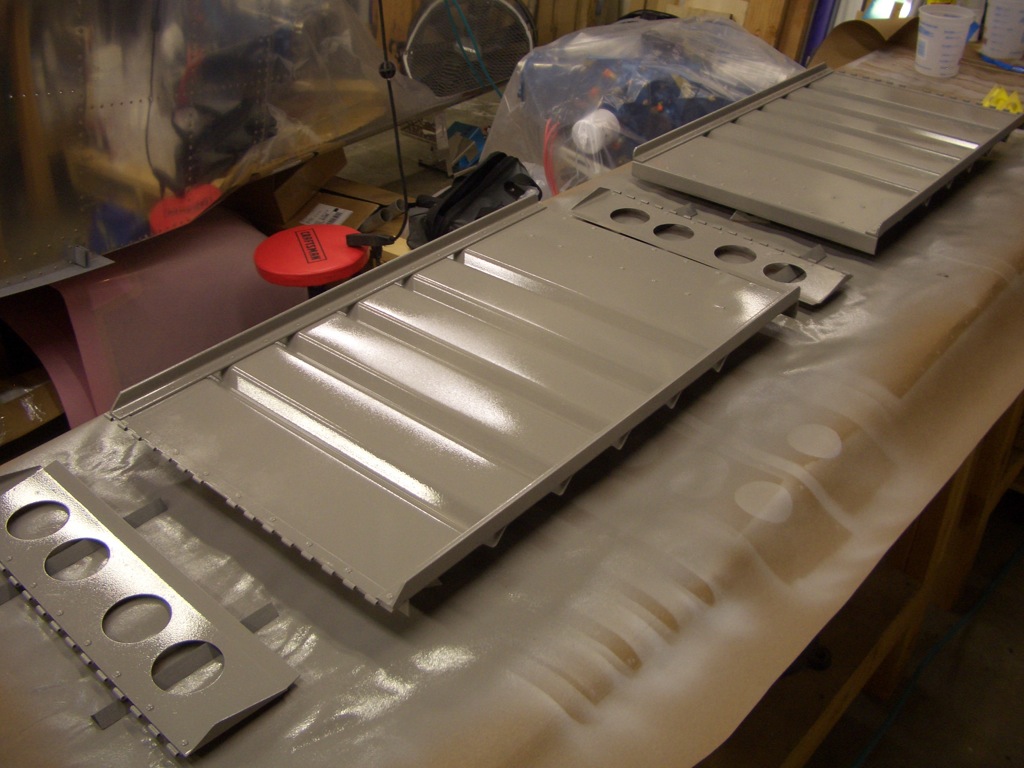

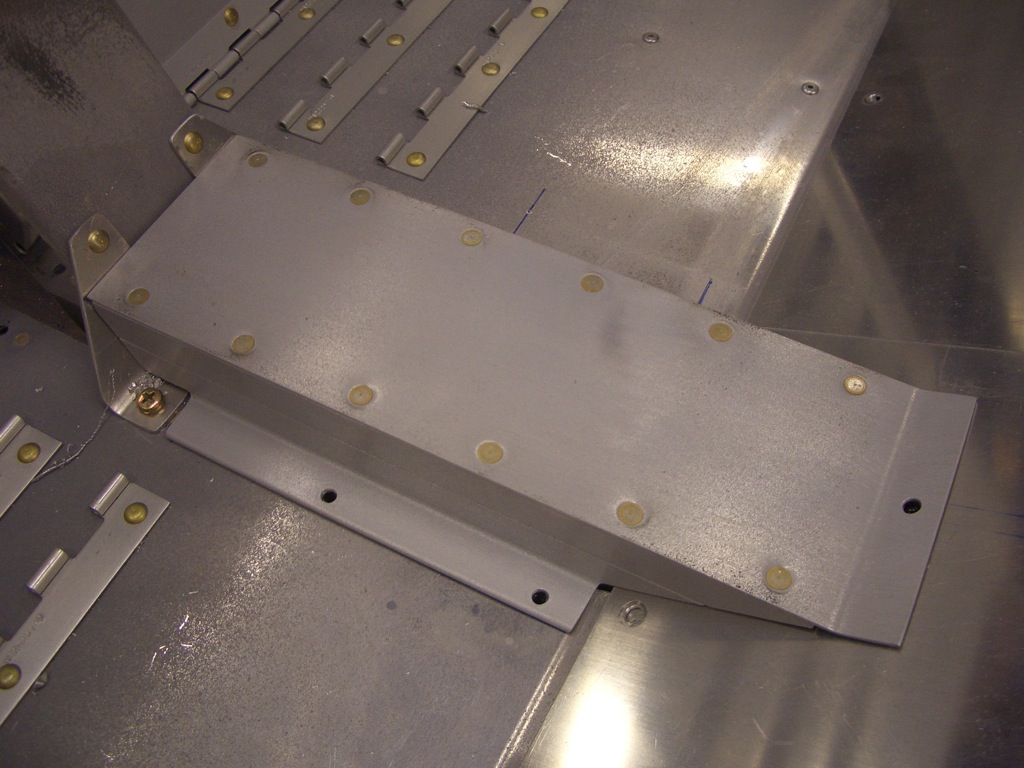

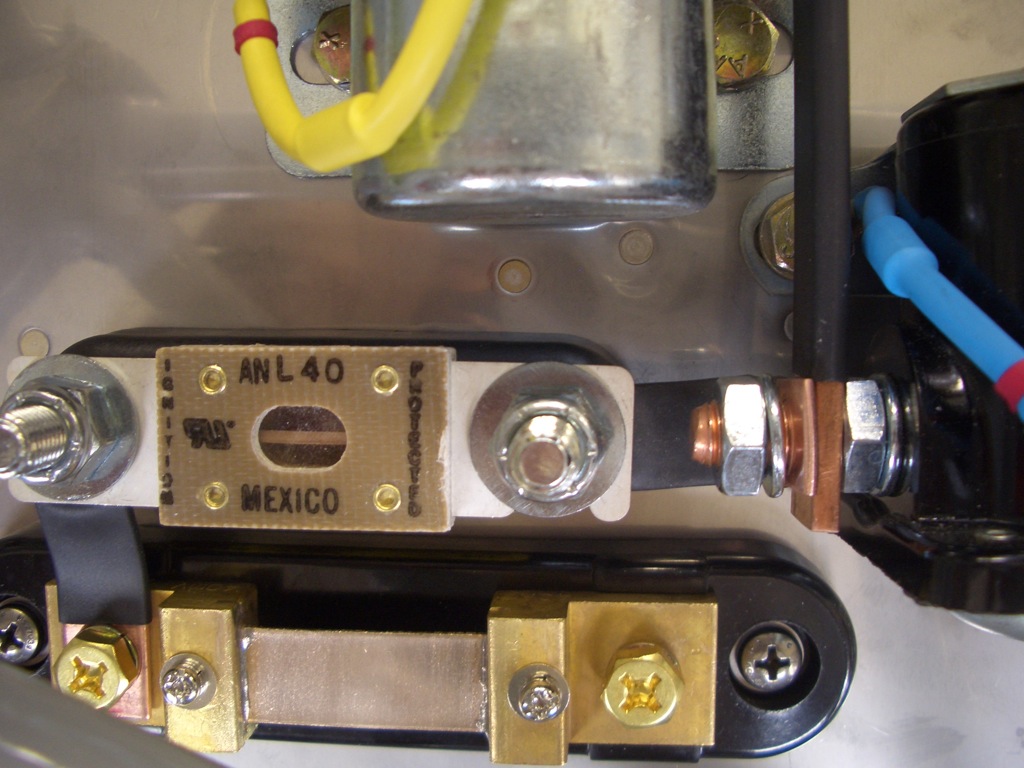

We primed and riveted the doublers for the shunt and ANL current limited and fabricated the bus bars that connect them to the input side of the starter contactor.

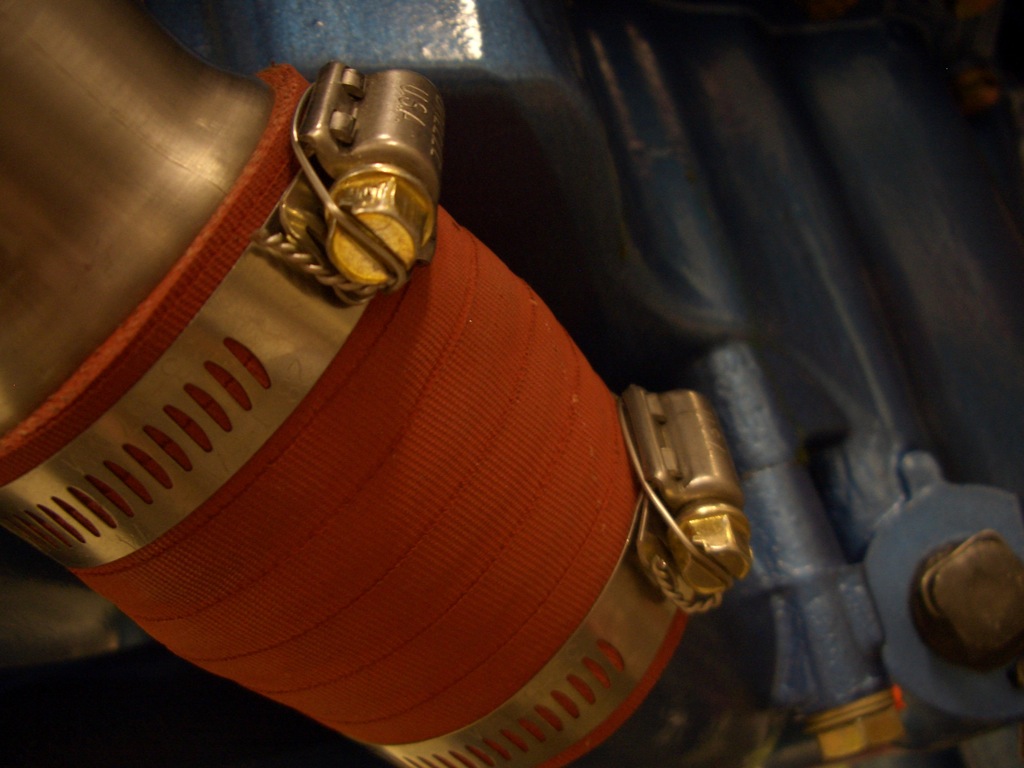

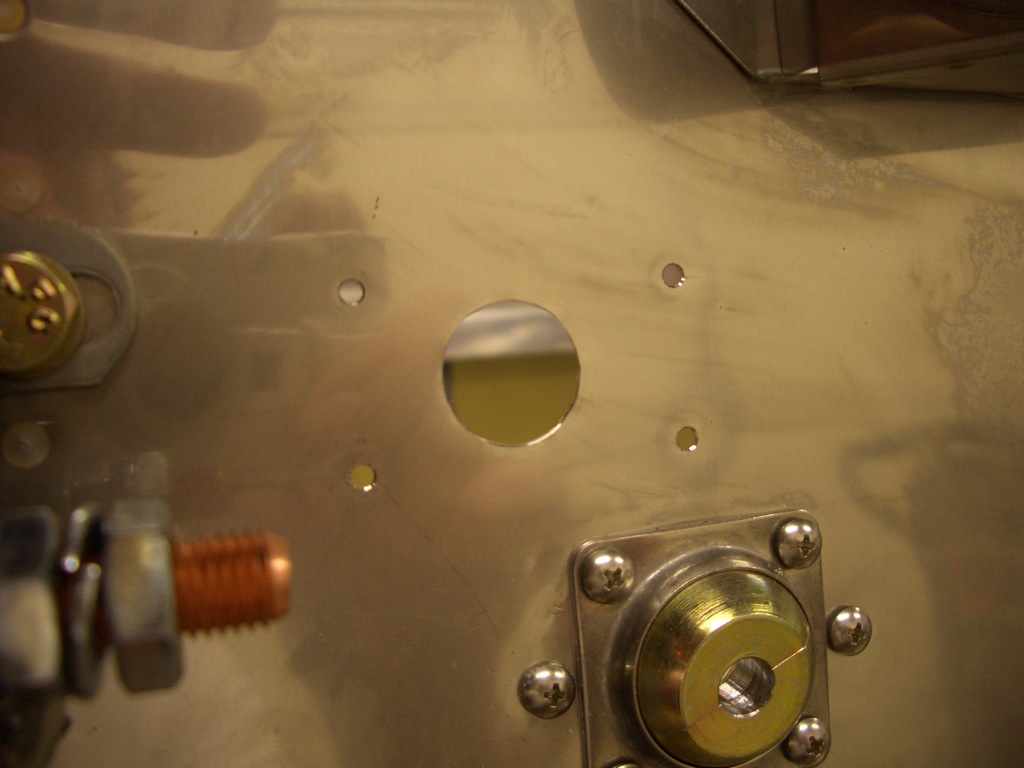

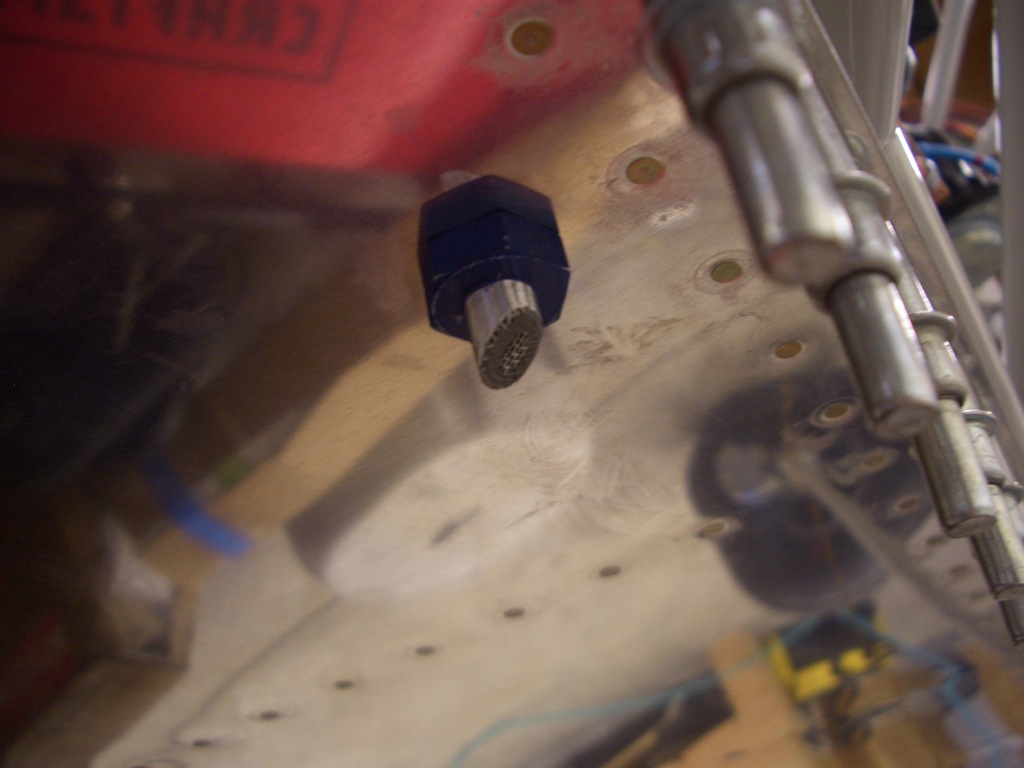

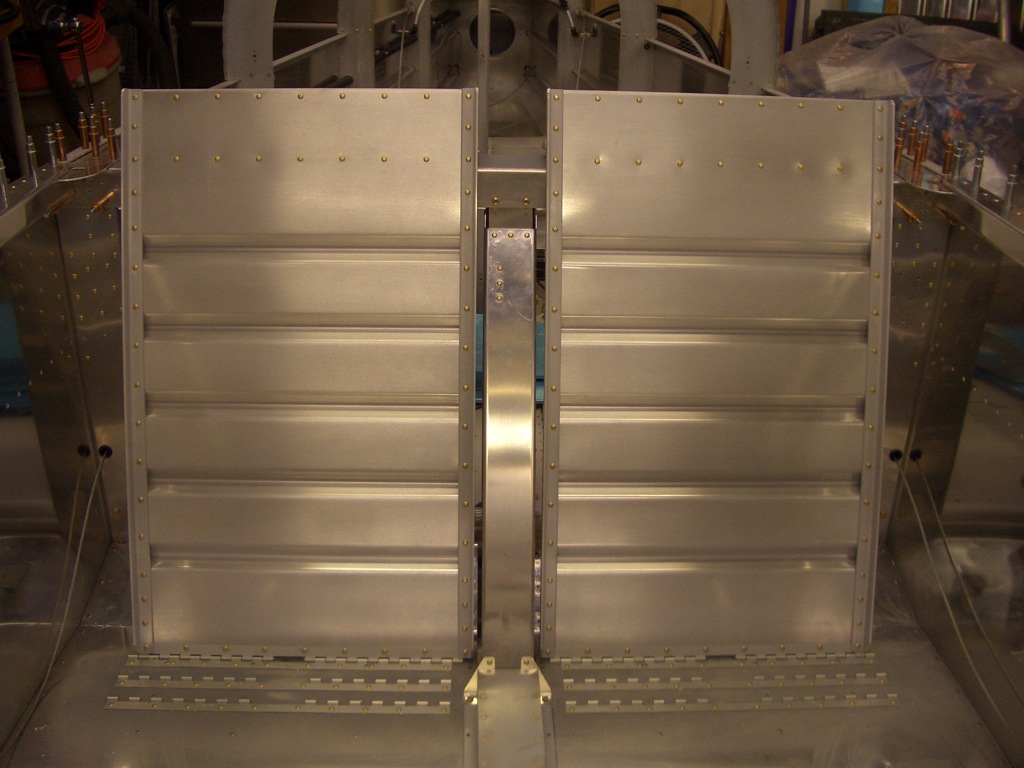

Next up, we drilled and mounted the Dynon manifold pressure sensor to the firewall. Finally, we riveted on a couple of nutplates and the parking brake doubler. You can also see that we riveted on the forward ribs and then reinstalled the pressure transducer. Afterward, I reinstalled the engine mount with landing gear and torqued/cotter pinned the nuts.

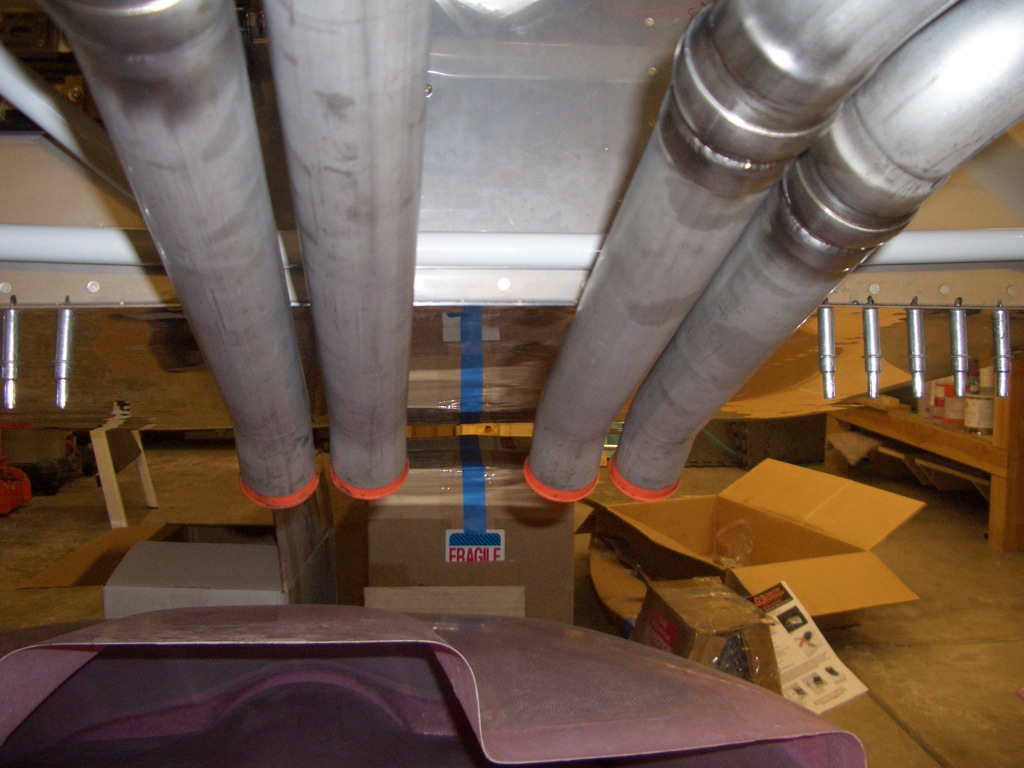

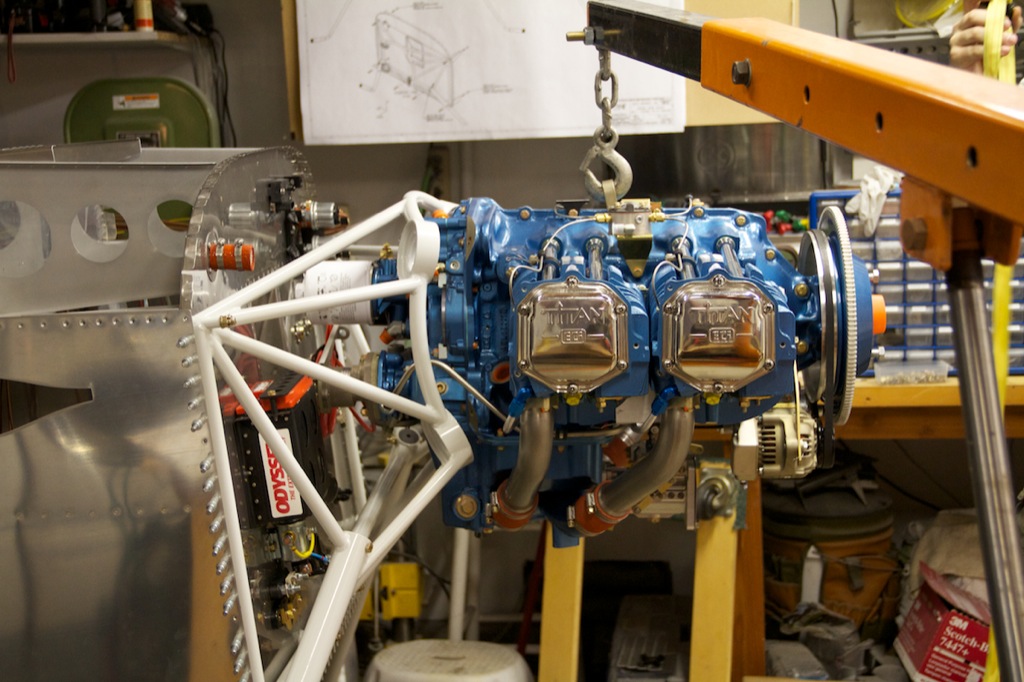

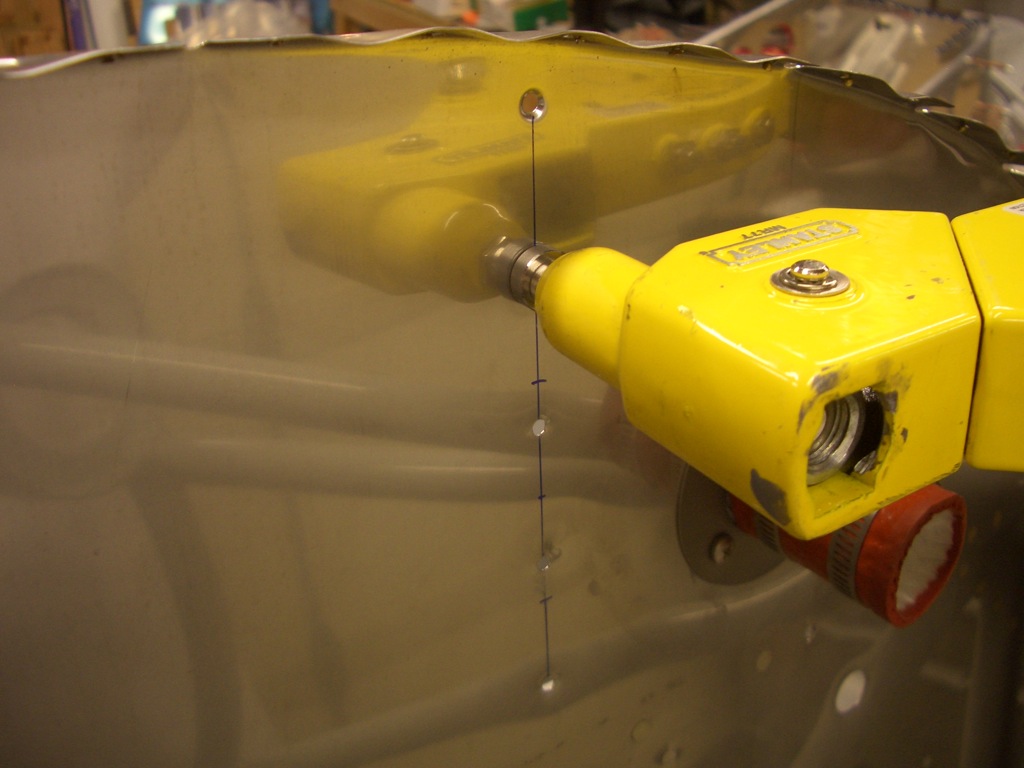

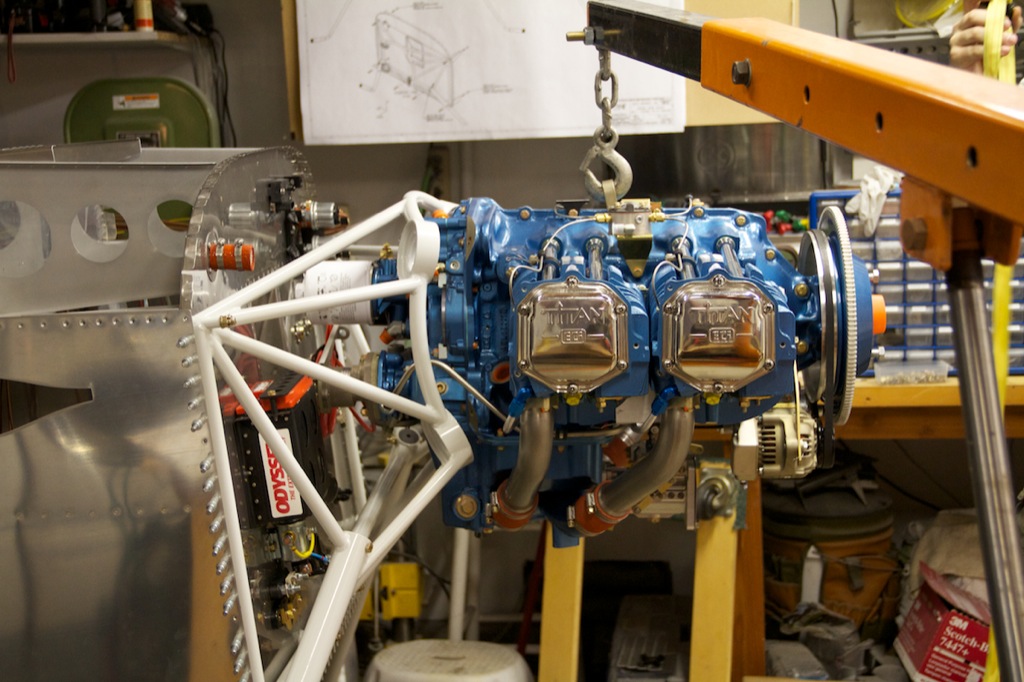

After dinner, we got started hanging the engine. I had been planning on having a few guys from EAA chapter 338 stop by and help, but after reading about the experience of a few builders, I thought we’d give it a try. We turned the plane around so the engine hoist had some smooth concrete to roll on. Here, we’ve just lifted the engine pallet up off the ground so that I can undo the bolts holding the engine to the pallet. I actually set the pallet gently back on the engine hoist legs so that it wouldn’t put any load on the bolts as I took them off.

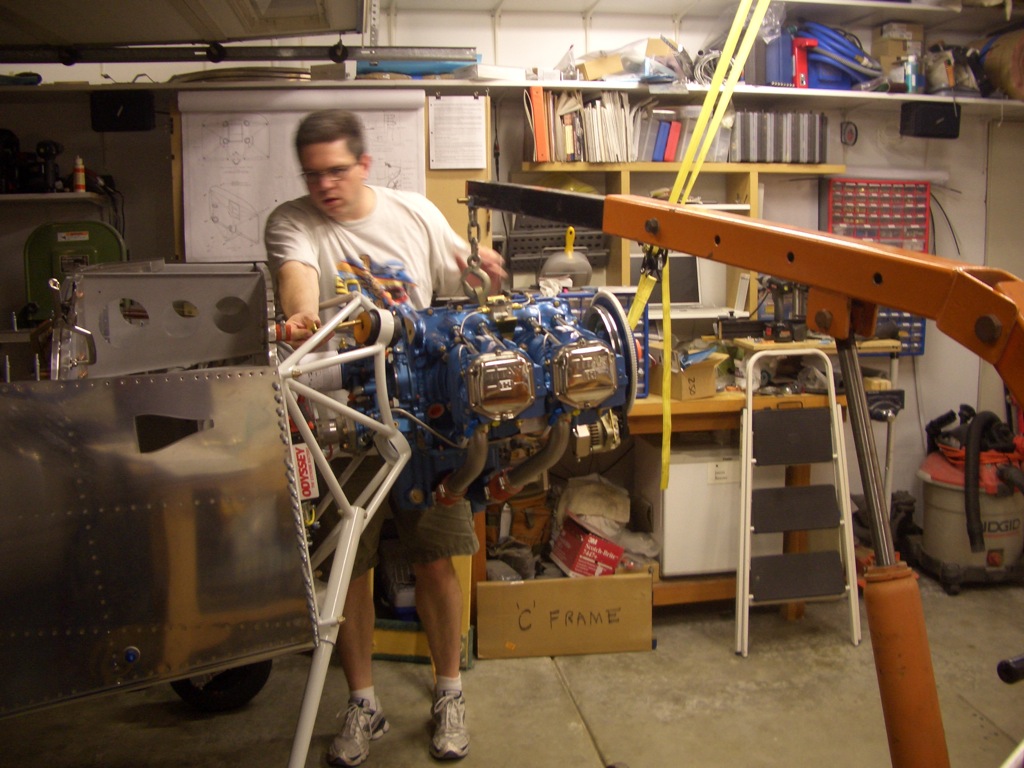

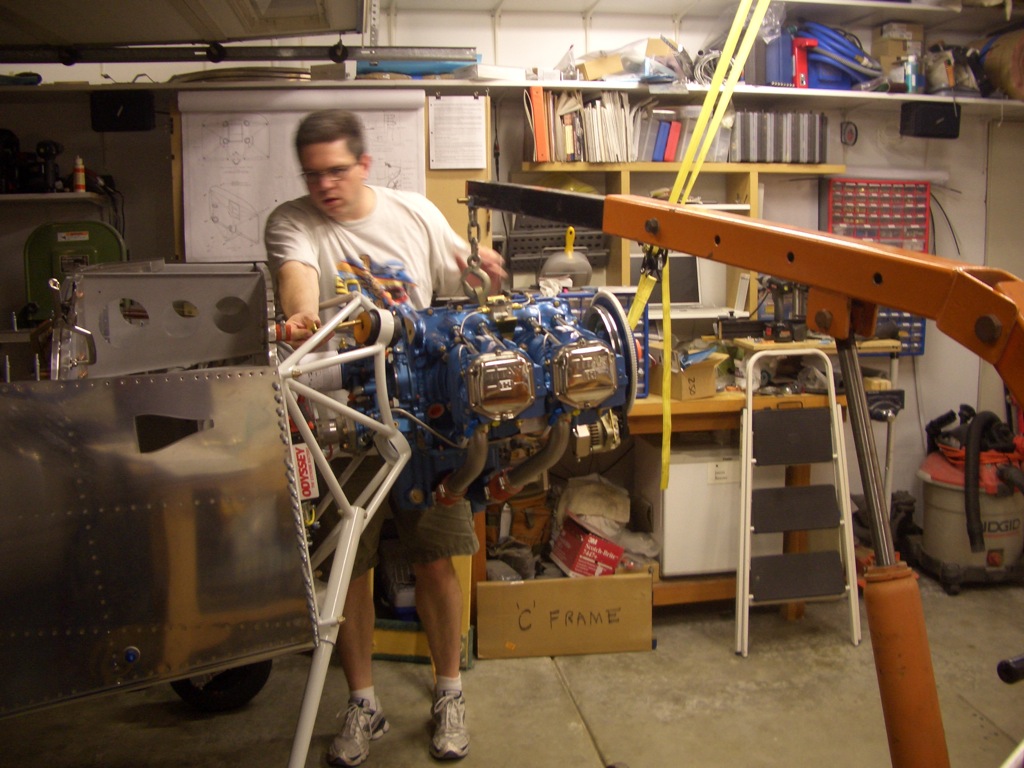

Here I’m getting the engine roughly in position. It was definitely a little nerve-wracking to have $30k worth of engine hanging 3 feet off the concrete. You can tell that the angle of the engine and the mount are still way off. Since I don’t have a load tilter, it’s probably easiest to change the angle of the plane. And yes, that is a garter hanging from the engine hoist (don’t ask).

We propped the tail up on my adjustable shop stool. I put some wood blocks under the tailwheel fork so that the wheel wouldn’t roll around. The spring is strapped to the stool. It looks precarious, but it’s actually pretty solid.

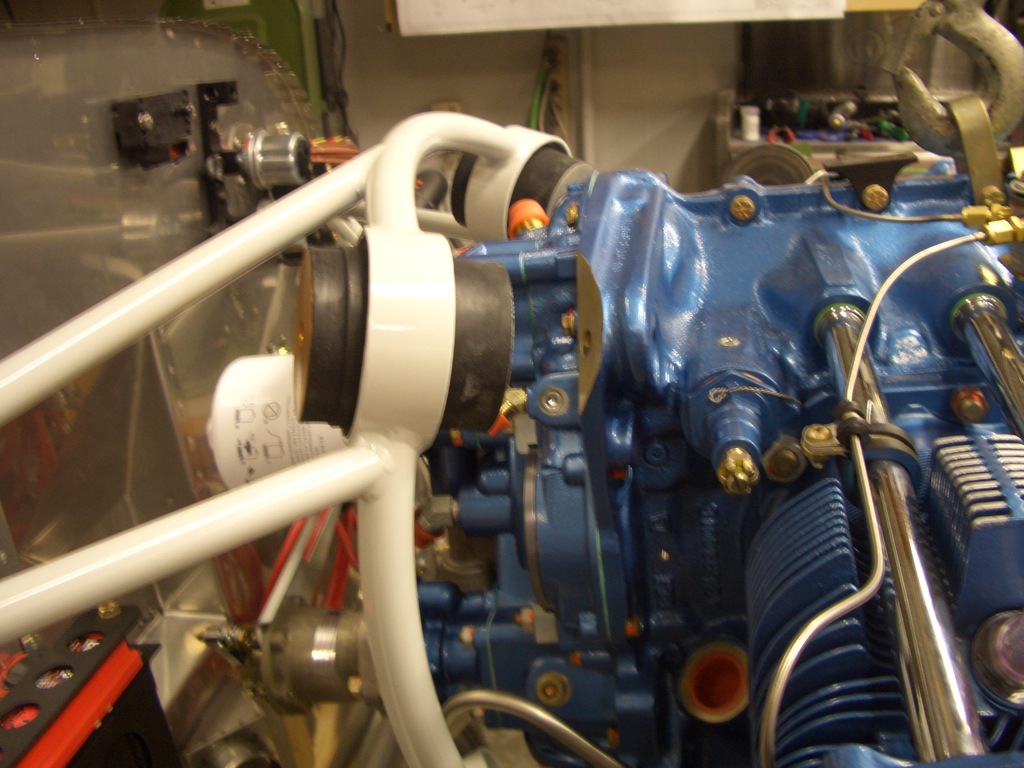

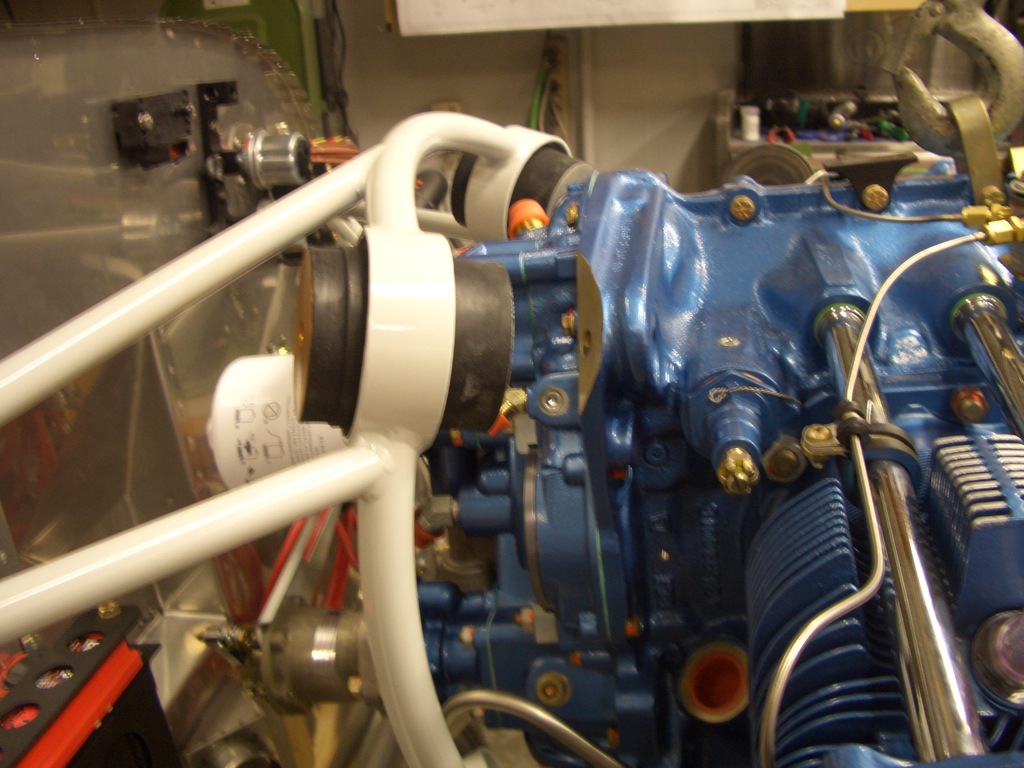

We’ve just about got the engine in place, but the tail is still too low. It’s close enough that I can push it into alignment though.

I used a little hillbilly engineering and rigged a tie-down strap to one of the rafters. I used this to lift the front of the engine enough that the bolt holes came into alignment.

Here, we’ve got the top two engine mounts in place and are positioning the engine and plane to get the holes in close alignment.

Here I’m installing the top two bolts. These went in pretty quickly and with only a little persuasion.

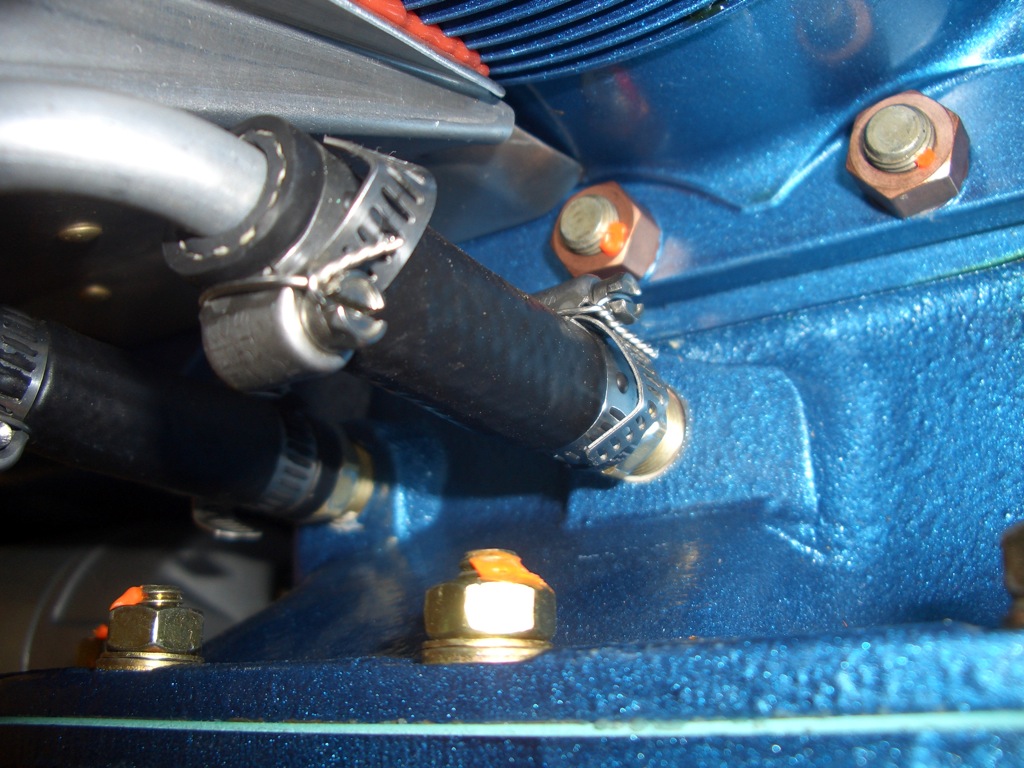

The third bolt (lower right) was not too much harder and went in with a little wiggling of the engine. The fourth bolt (lower left) was a little more of a pain. I had to tighten the other three bolts fairly tight and still needed to use a bullet to move the rubber mount a little when getting it in.

I still need to torque all the bolts, but the engine is hung! The tail is still up on the stool in this shot which is why the plane looks fairly level.

Here’s a shot from the bottom for no good reason.

Now the tail is back on the ground, so this is the attitude the plane will normally be in.

Here I am posing with my newly hung engine.

The plane is now back in its spot in the garage. This has been a long day, and I’m beat, but I’m totally stoked to have hit this milestone.