I lucked out on the purchase of a propeller earlier this month. Early last year, a number of builders organized a group buy through American Propeller Service for the Whirl Wind Aviation 200RV propellers. I missed out on the group buy because it happened right around the time I started on the kit and I wasn’t looking for a prop yet. Luckily another builder had a $1,000 deposit in this group buy that he needed to sell. By the time that I saw his email though, at least four people had responded that they’d take it. I sent him an email and offered him $1,500 for his deposit, and that was enough to put me at the top of the list. I sent him the money and he transferred the slot to me.

I paid for the rest of the prop and ordered a PCU5000 governor at the same time. Since American Propeller Service is based in Redding, CA and I’m in San Jose, CA, I decided to fly our Cardinal up to get the prop. I got up at 4:50 and was wheels up by 6:50.

Here’s a shot of the north bay with the mothball fleet visible near the center of the picture and Napa, CA just beyond.

I got a tour of the propeller shop as well as the engine shop where we had our Cardinal’s cylinders overhauled last year. They have a great shop and really do outstanding quality service. If you need a prop, give Kevin Russell a call there and tell him I sent you.

Afterward, I loaded the prop, spinner and governor into the back of the plane and headed home.

Redding, CA is just south of Mt. Shasta, and it’s visible on a clear day for 100 miles in any direction.

The flight up was into heavy headwinds, so the 192nm flight took nearly 2 hours. The return flight was quick though with 150+kt ground speeds for most of the flight and 170+kt ground speeds as I started a shallow descent out near the Travis Air Force Base.

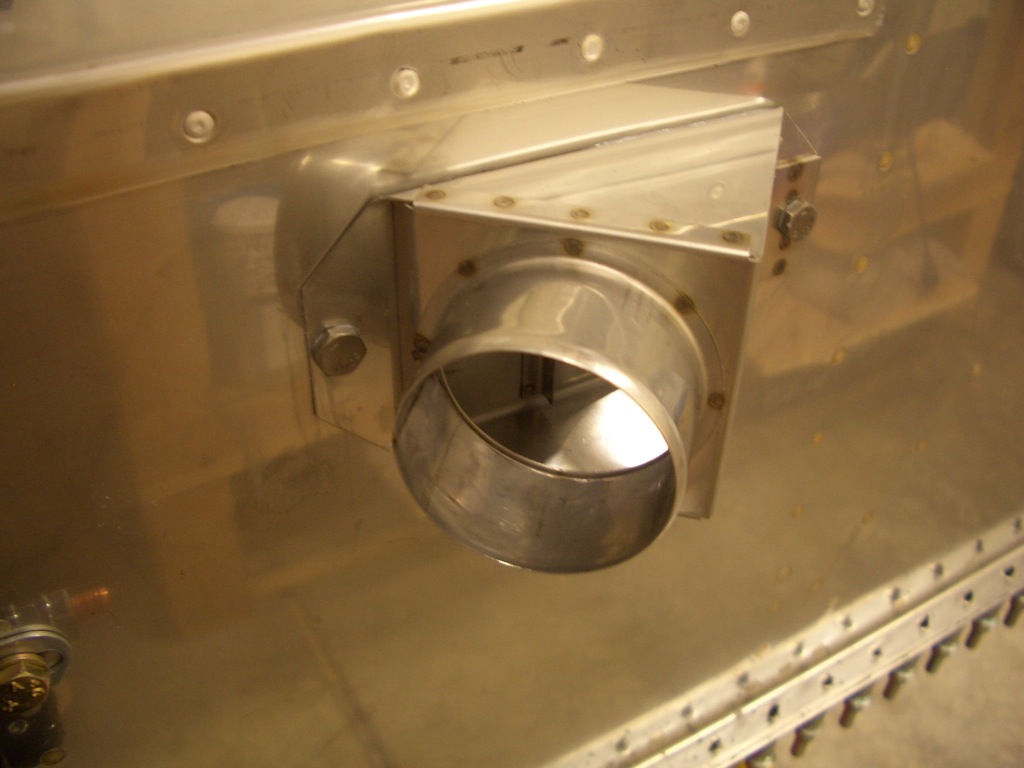

Here’s a shot of one of the blades. The 200RV is a hollow carbon fiber blade with a nickel leading edge erosion shield.

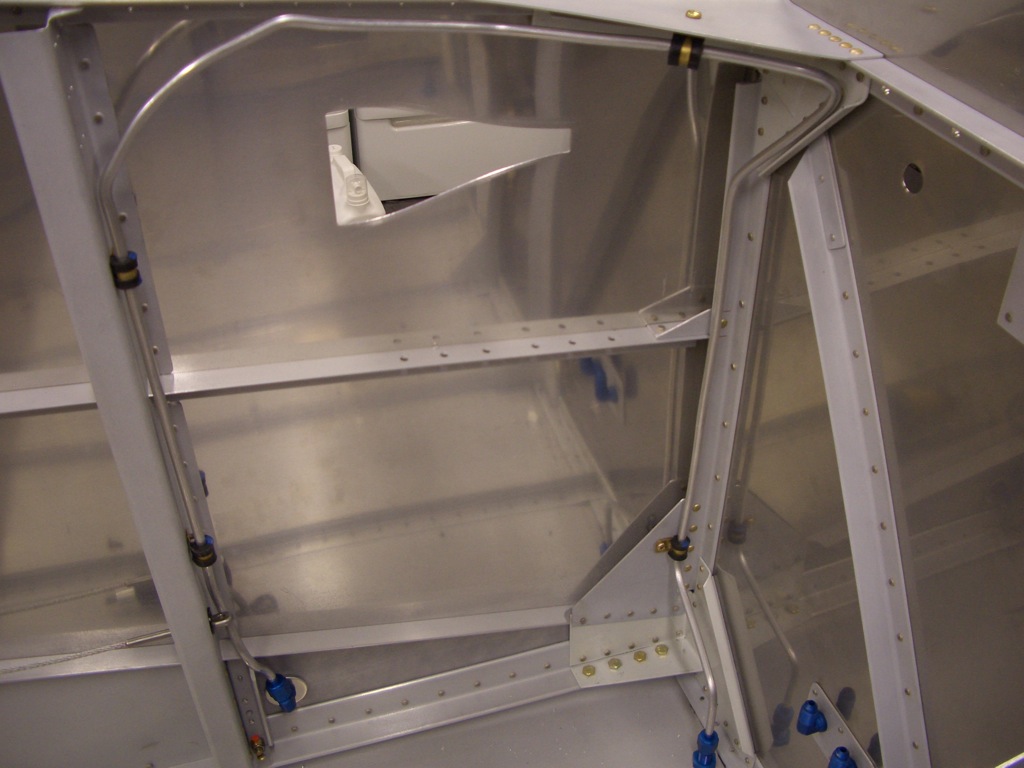

Here’s the tip of the blade using my hand as a reference so you can see just how short the chord is at the tip.

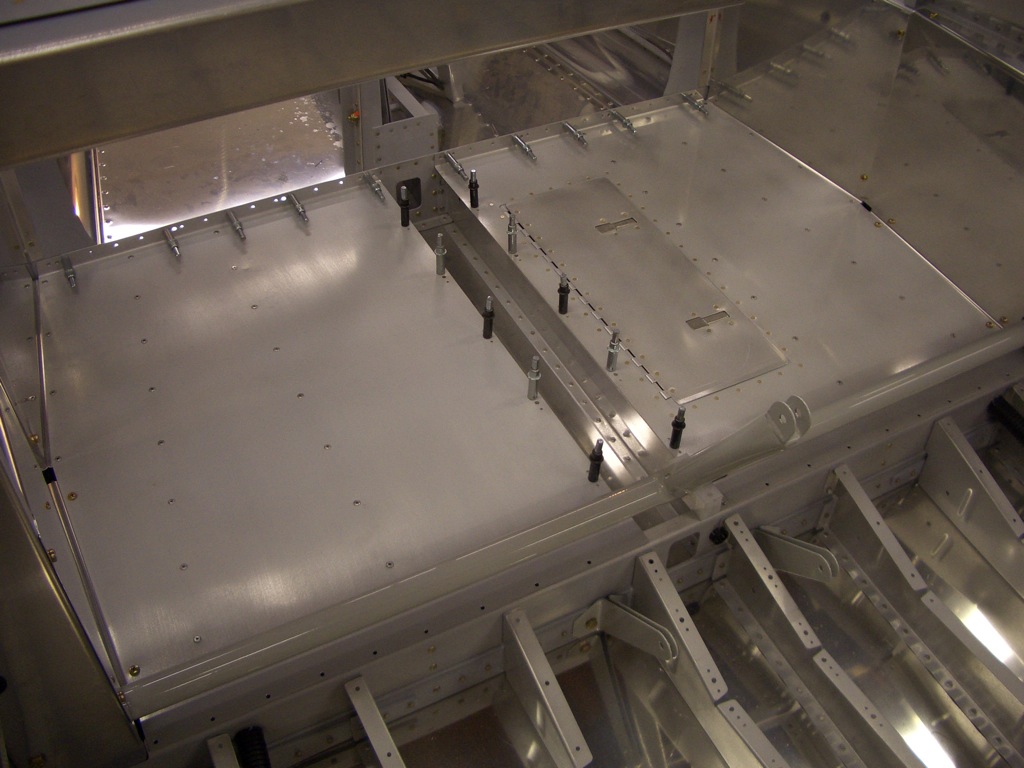

Here’s a shot of the widest part of the blade with my hand as a reference.

The Whirl Wind propellers all come with a spinner that is ready to bolt on. With any other prop, I’d have to fit the Van’s spinner myself.

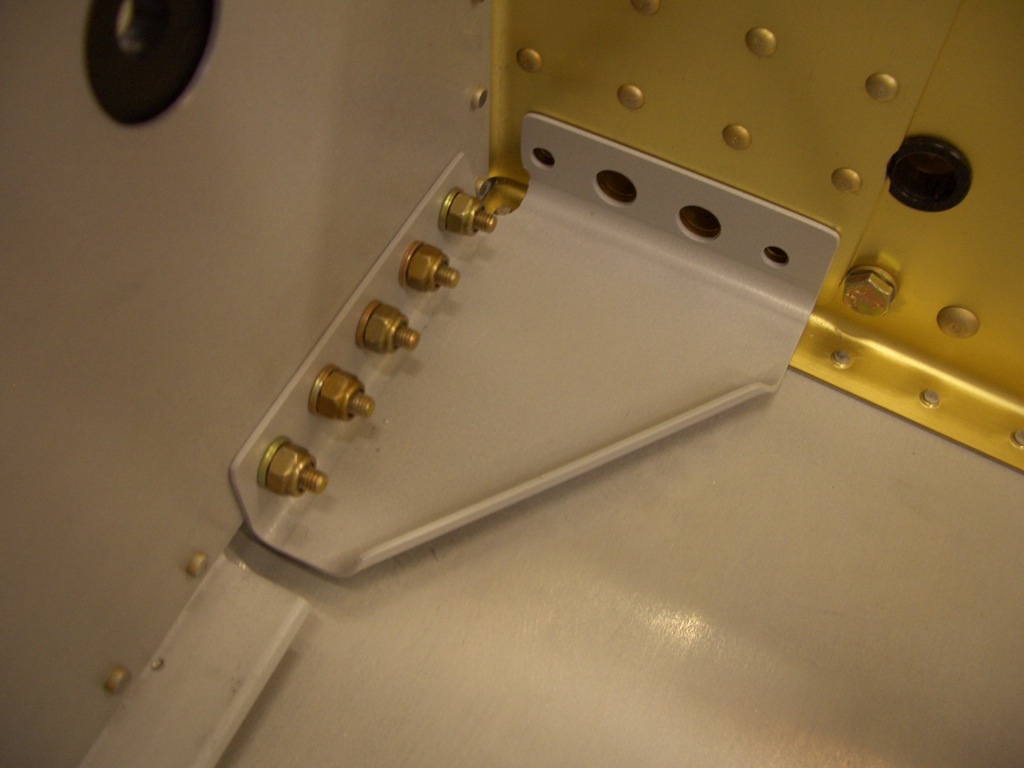

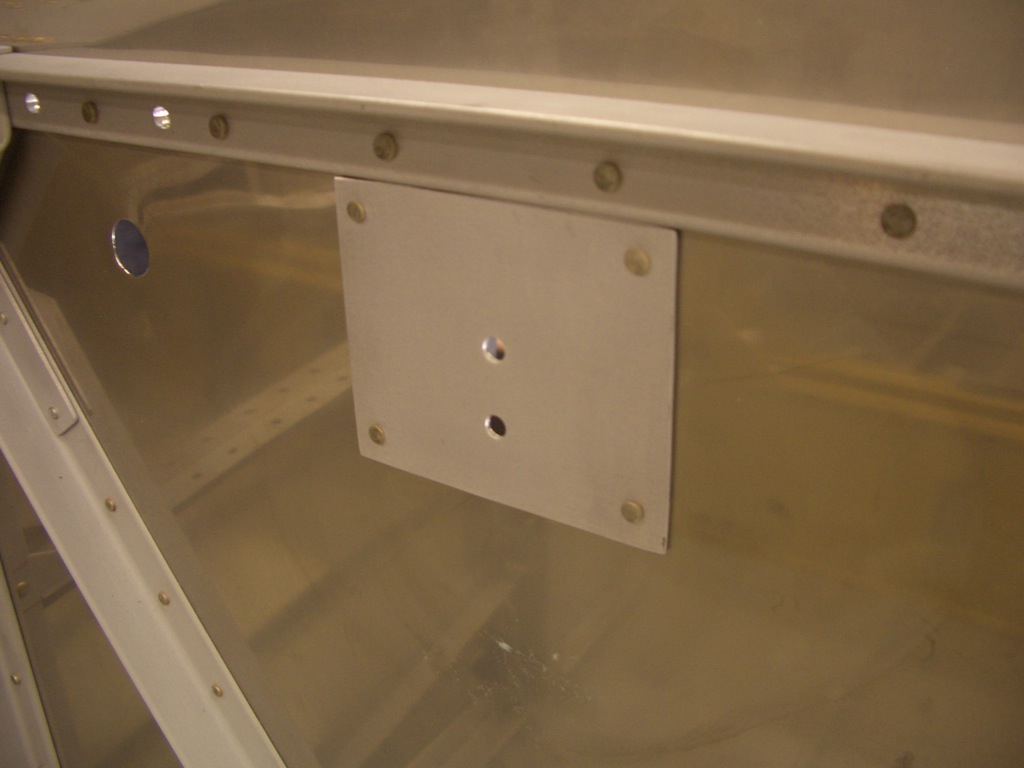

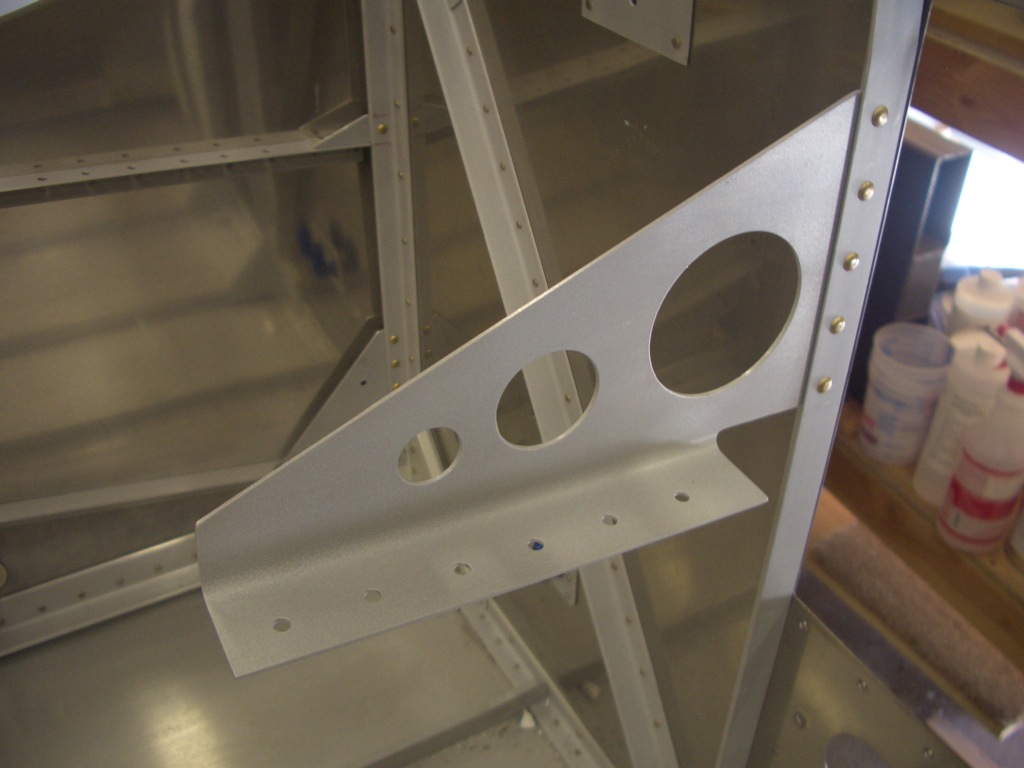

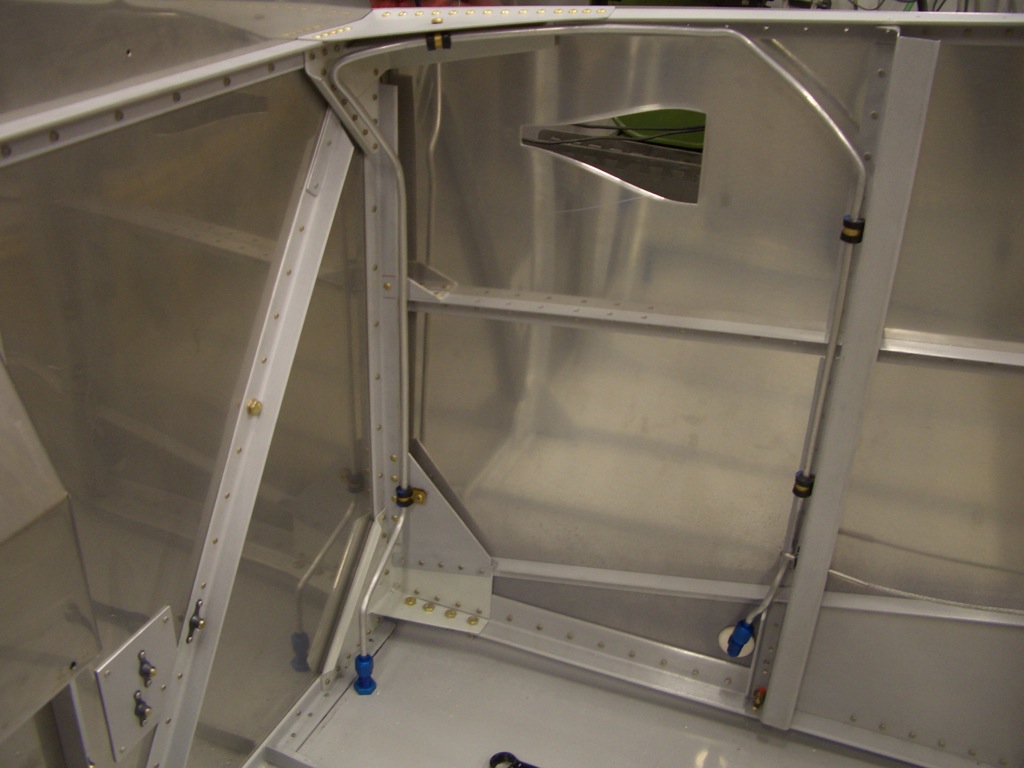

Here’s the aft mounting plate for the spinner. The entire spinner is made of carbon fiber, so I should never have to worry about this cracking.

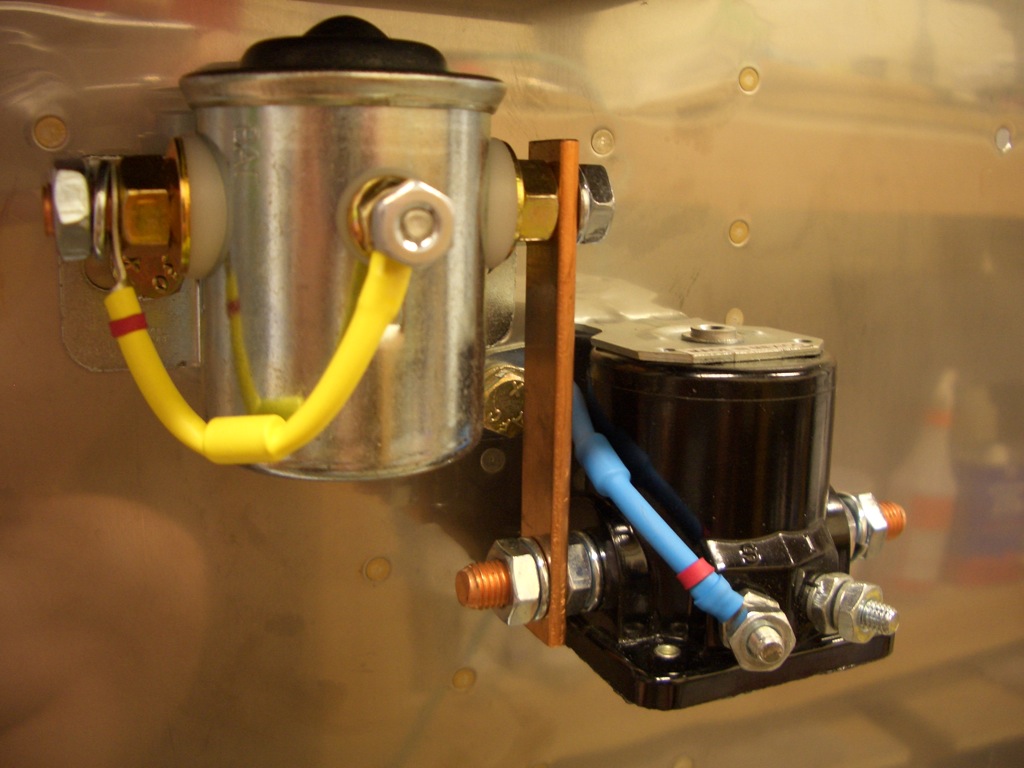

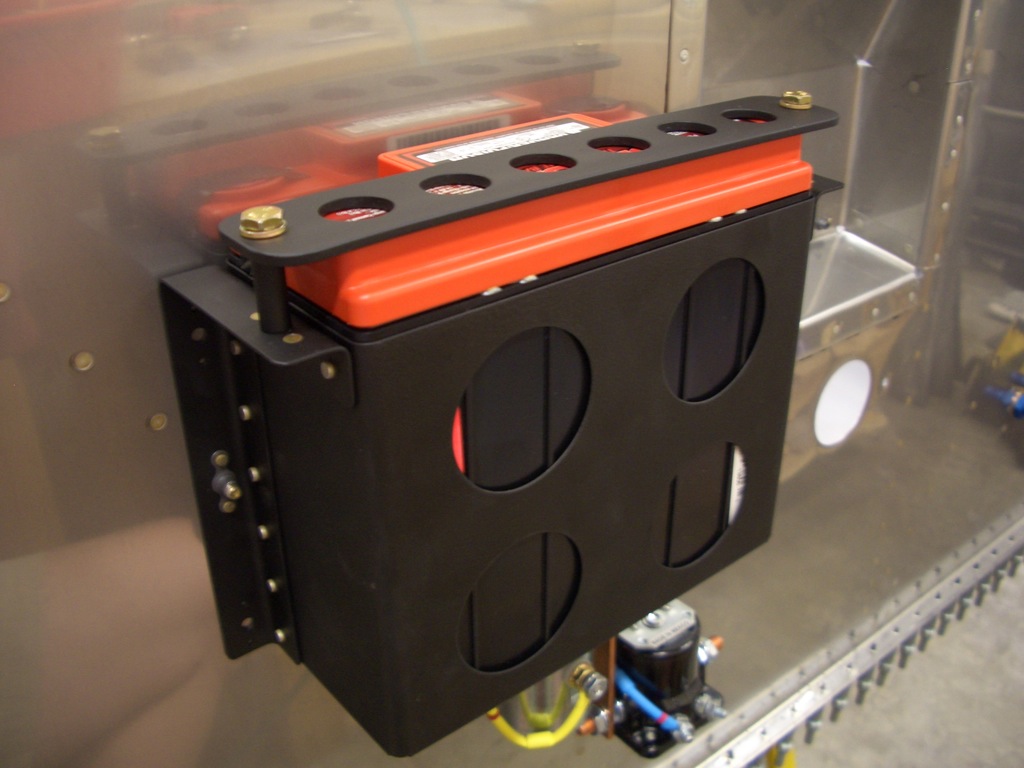

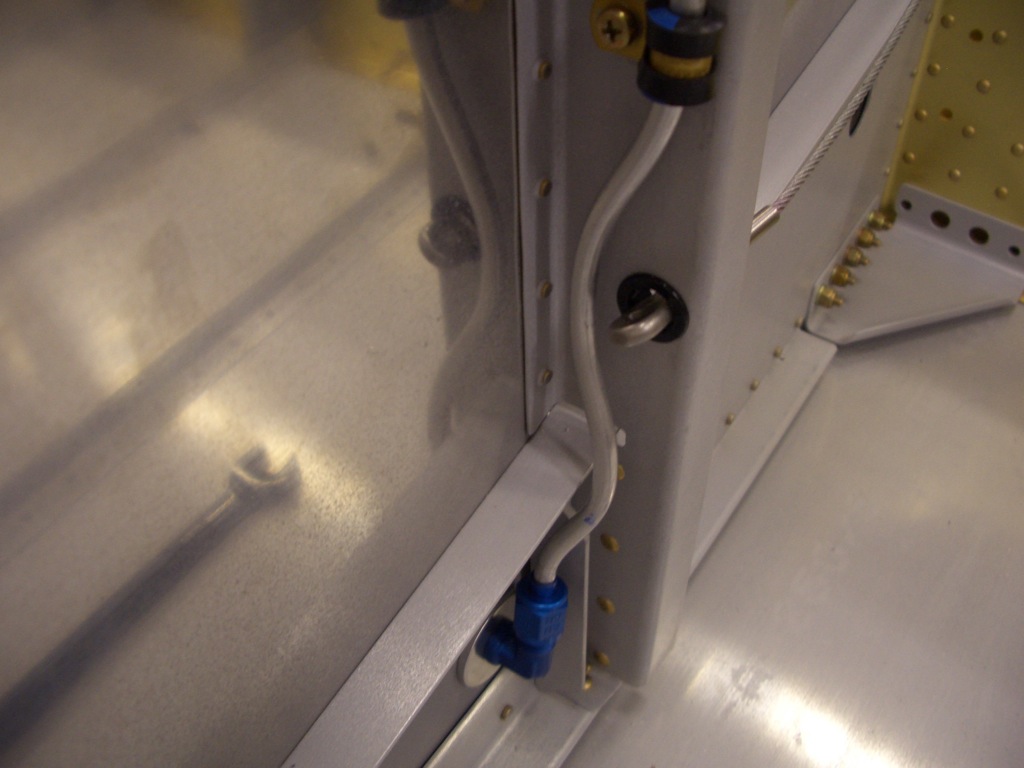

Here’s the governor that I picked up. This will bolt on to the back of the engine and regulates oil pressure to the prop to vary blade pitch.