After an acro lesson this morning in the Citabria, I managed to get a couple of hours in on the plane today. My buddy Andre stopped by and we finished off the pile of small parts and I got through a big chunk of the center section deburring. I still have the longerons and skins to do and then the priming can begin.

More Fuselage Deburring

I made it through a few more parts today. This is by far the biggest pile of parts that I’ve ever had to debur at one time, so it’s taking me longer than normal to get through them all.

Ordered Finishing Kit

I faxed in the order for my finishing kit today since Van’s is raising prices on February 1st. I intentionally wanted to wait until pretty close to the deadline so that I would end up late in the queue since I won’t be ready for the finishing kit in 8 weeks (the normal lead time). I’m hoping that the rush of orders will push my delivery out to 12-16 weeks.

Since I’m going with the AeroSport Power IO-375, I ordered the Dynafocal I engine mount with a cowl for the parallel valve engine with horizontal induction. Since I’m going with a WhirlWind propeller, I also deleted the spinner. I will be deleting the wheels and brakes from the finishing kit since I’m upgrading those to Grove units, and I will also be deleting the tires and tubes since many consider them fairly low quality. I’ll replace them with Condor tires and Michelin AirStop tubes.

Deburring Fuselage Components

No pictures tonight since they wouldn’t look any different than yesterday. I deburred more of the pile of small parts and got the tailcone deburred. I’ll probably have at least a few more deburring sessions before I can start priming components.

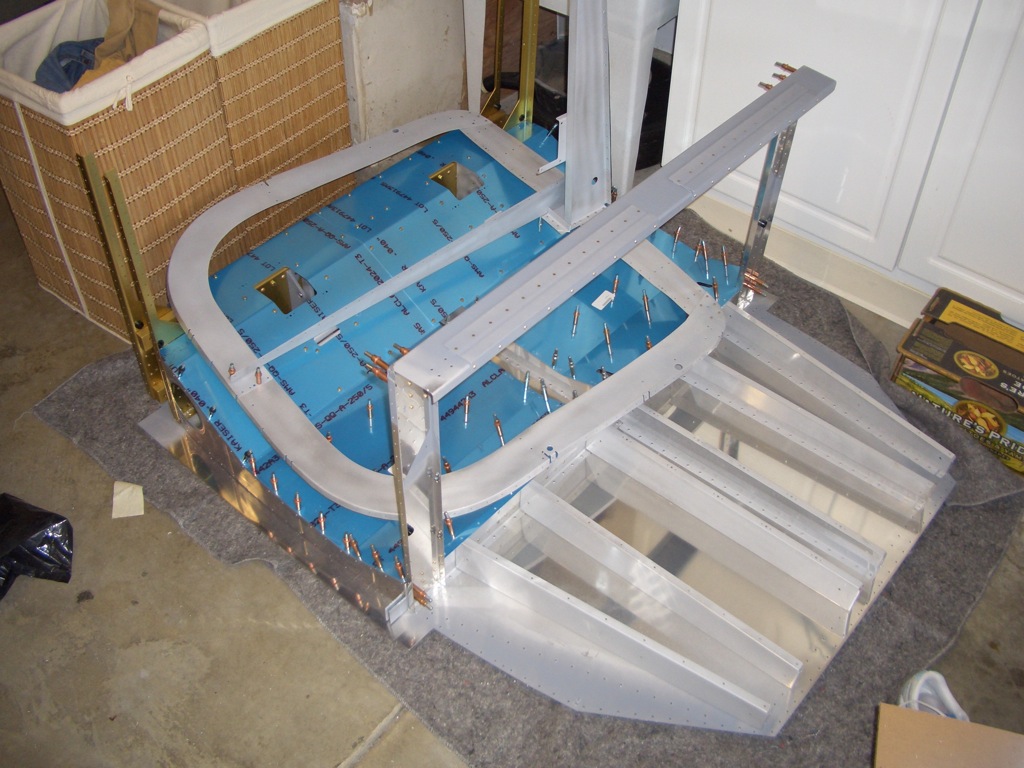

Disassembled Fuselage

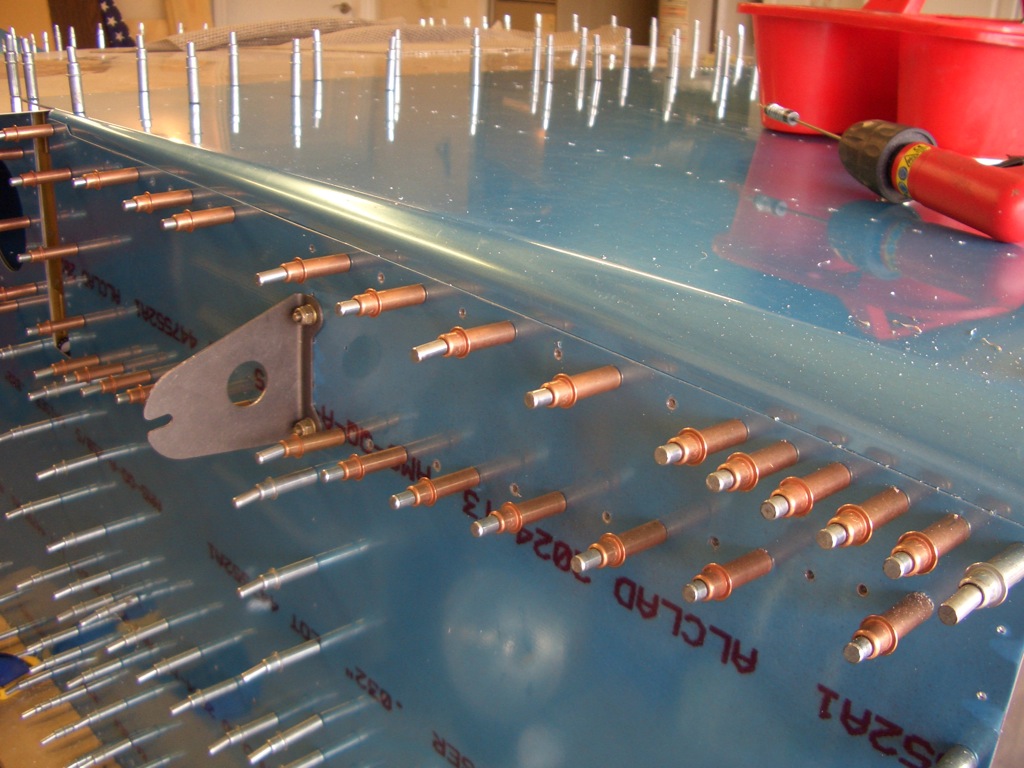

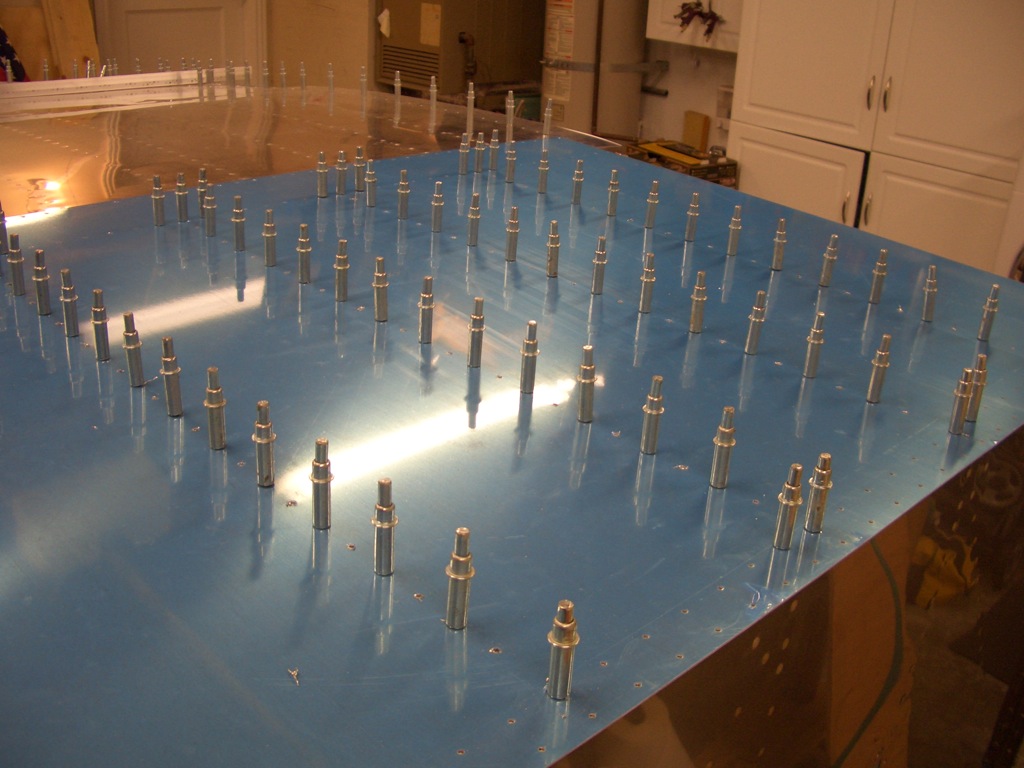

I got started today by finishing up the remaining drilling that needed to be done before disassembling the fuselage. First up is to match drill the outboard seat ribs to the side skins.

I also drilled the lower longeron to the side and bottom skins as well as the gear web and lower engine mount.

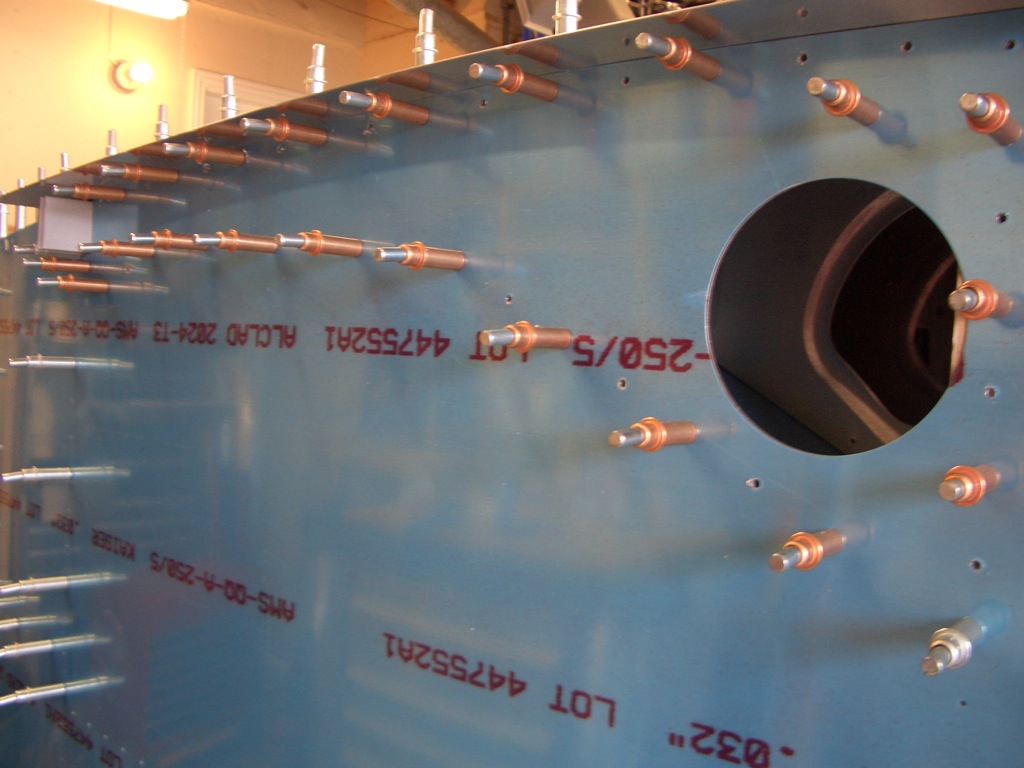

Two holes on the bottom skin just aft of the firewall need to be enlarged to 7/16″ for the fuel vents.

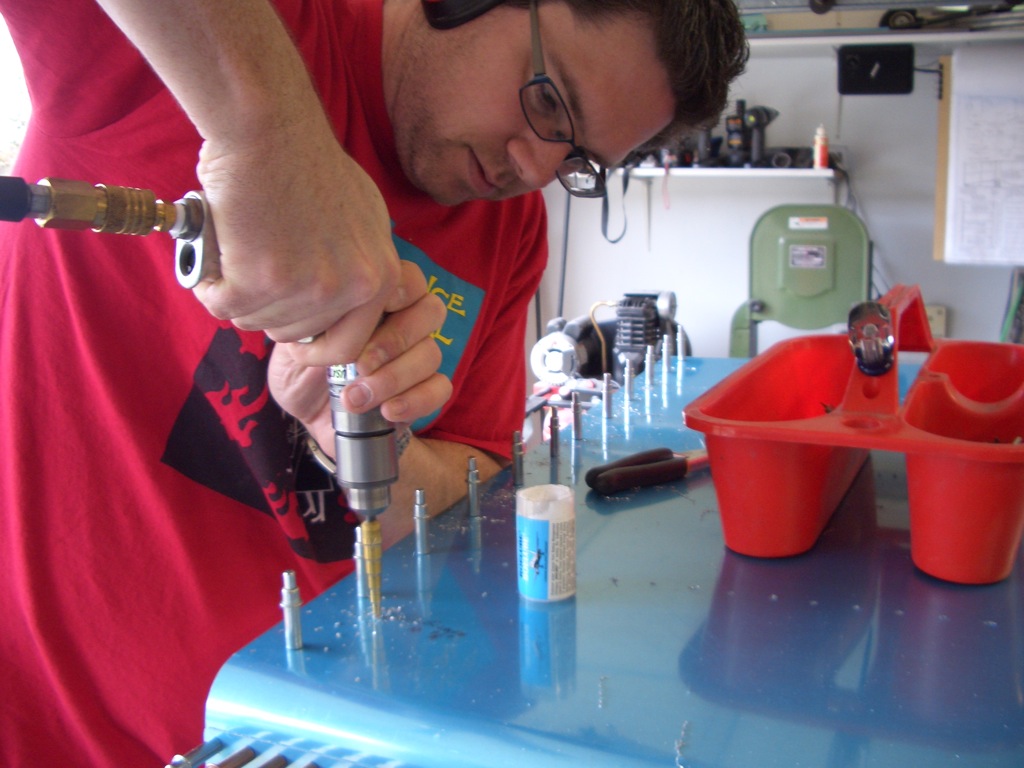

Andre took a picture of me drilling the other one.

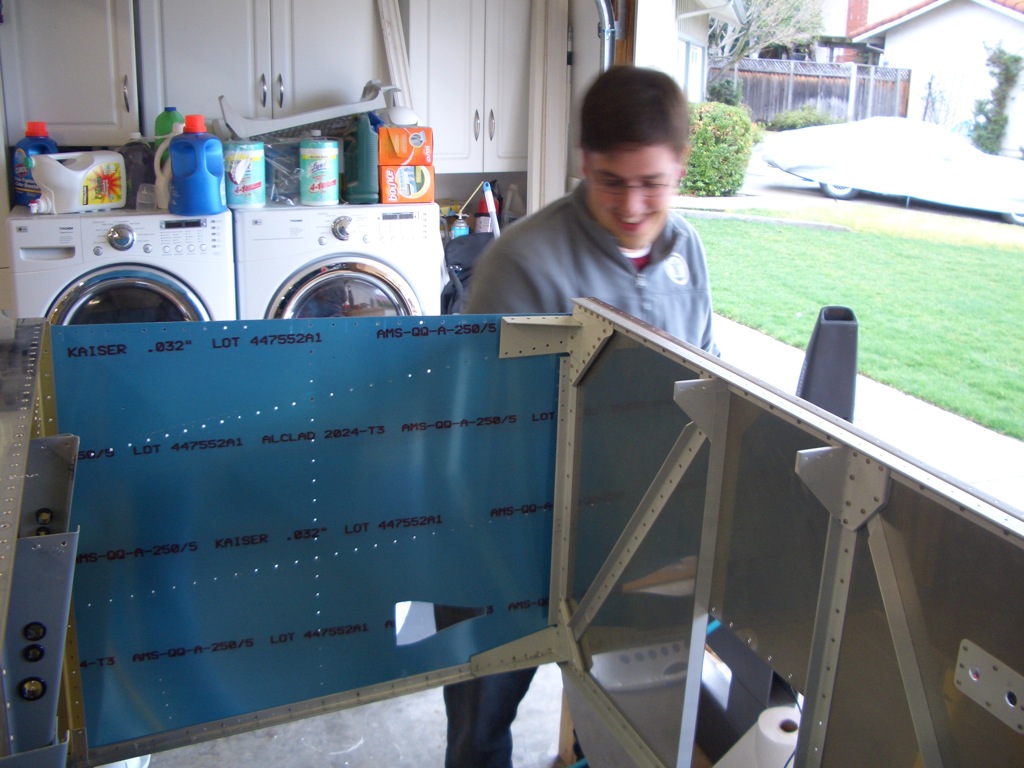

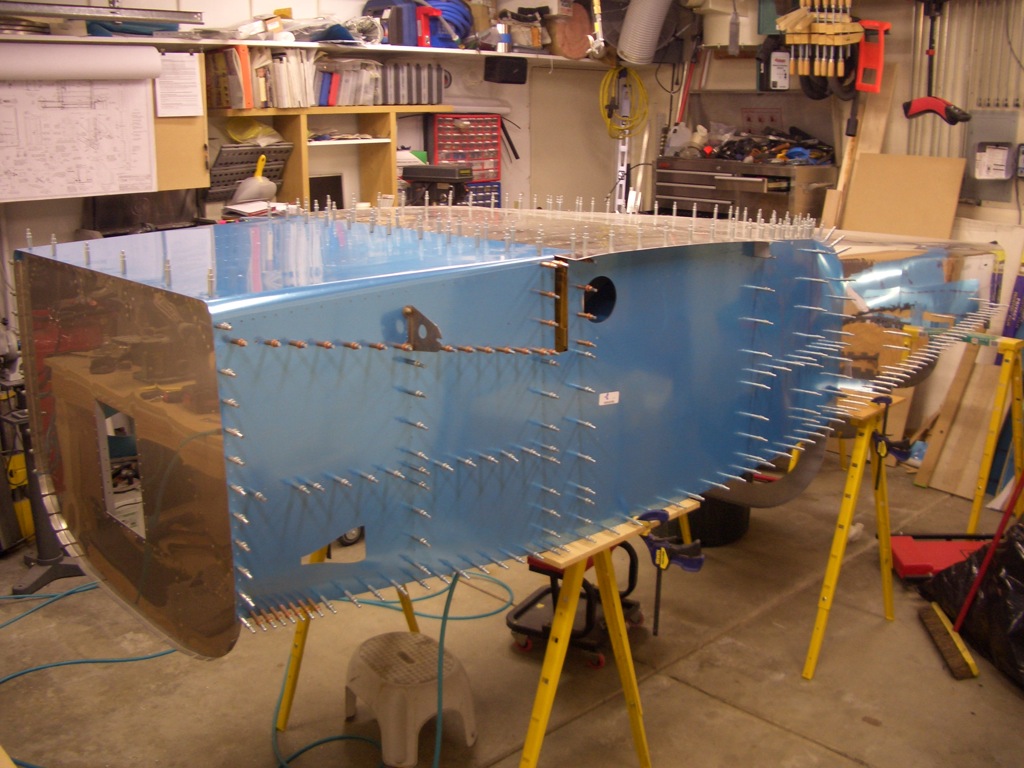

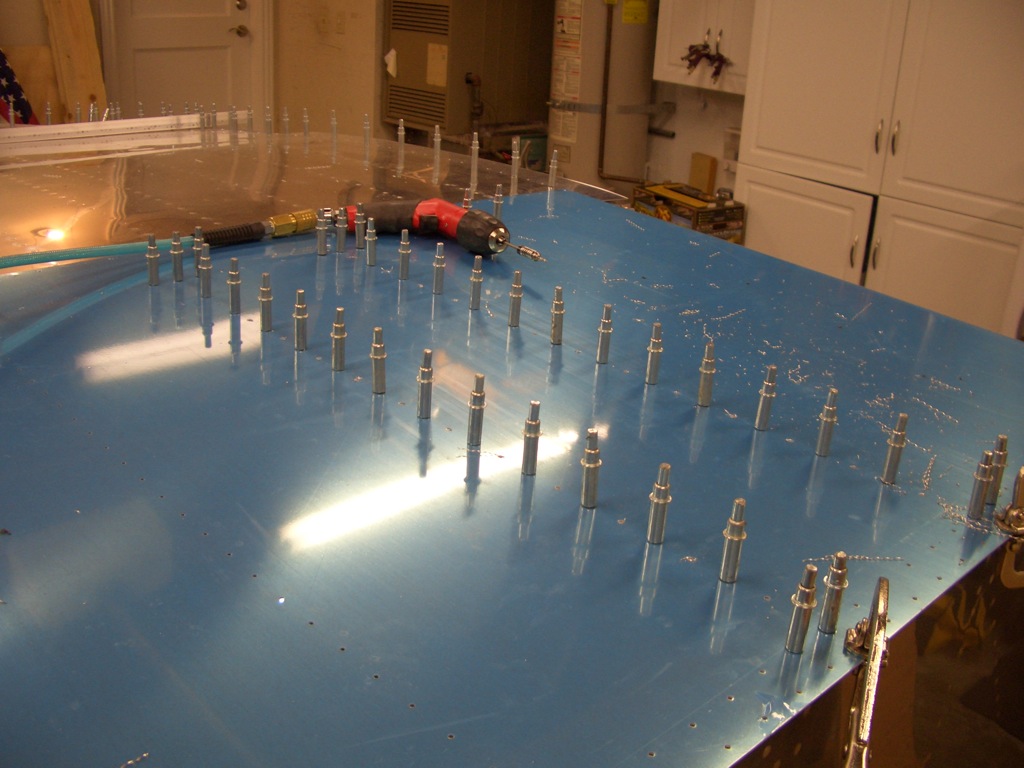

After drilling the side skins to all of the various bulkheads and drilling the center section bottom skin to the tailcone, we started disassembly.

Here’s the growing pile of parts from the disassembly. My cleco tote is overflowing with clecos again.

Finally, we separated the center section from the tailcone.

The tailcone is all that is left on the sawhorses.

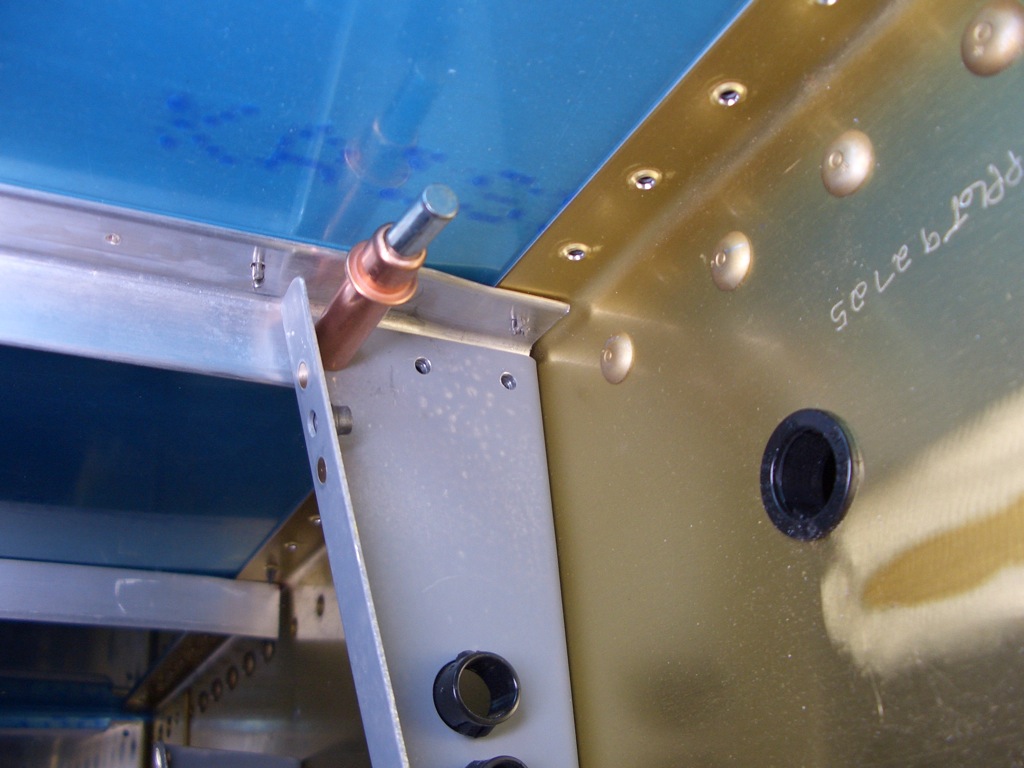

I next started working my way through a small list of tasks left to complete before priming. Here, I’ve riveted K1000-08 nutplates to the outboard side of the lower engine mount gussets. These will be used to anchor the vent line.

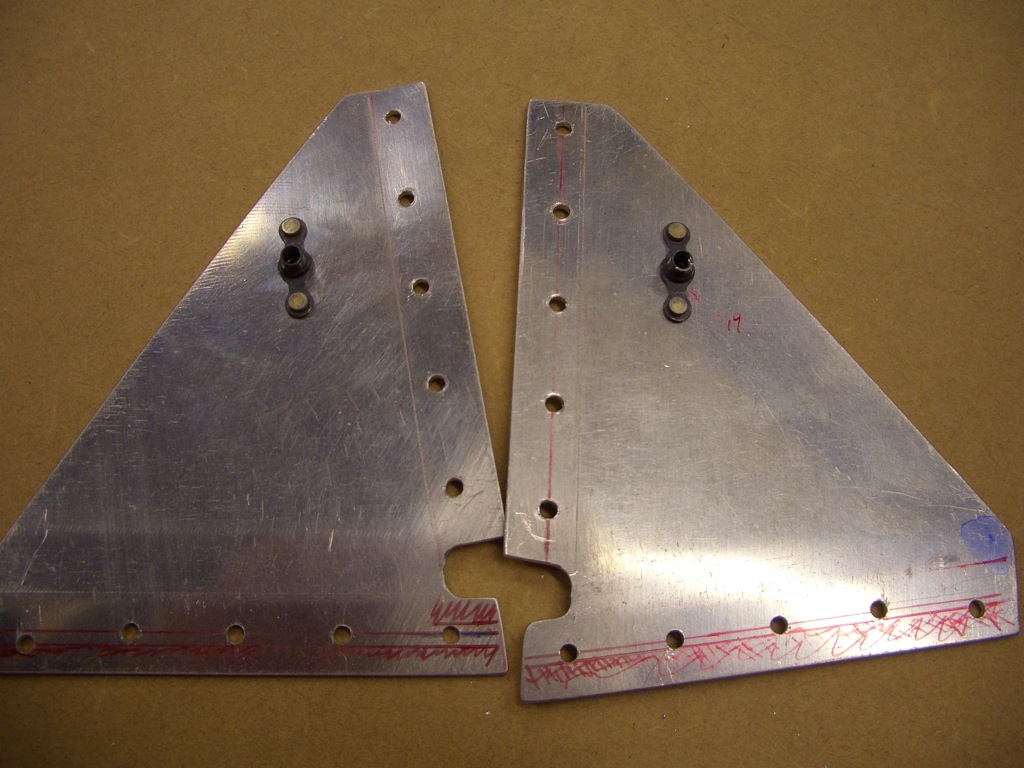

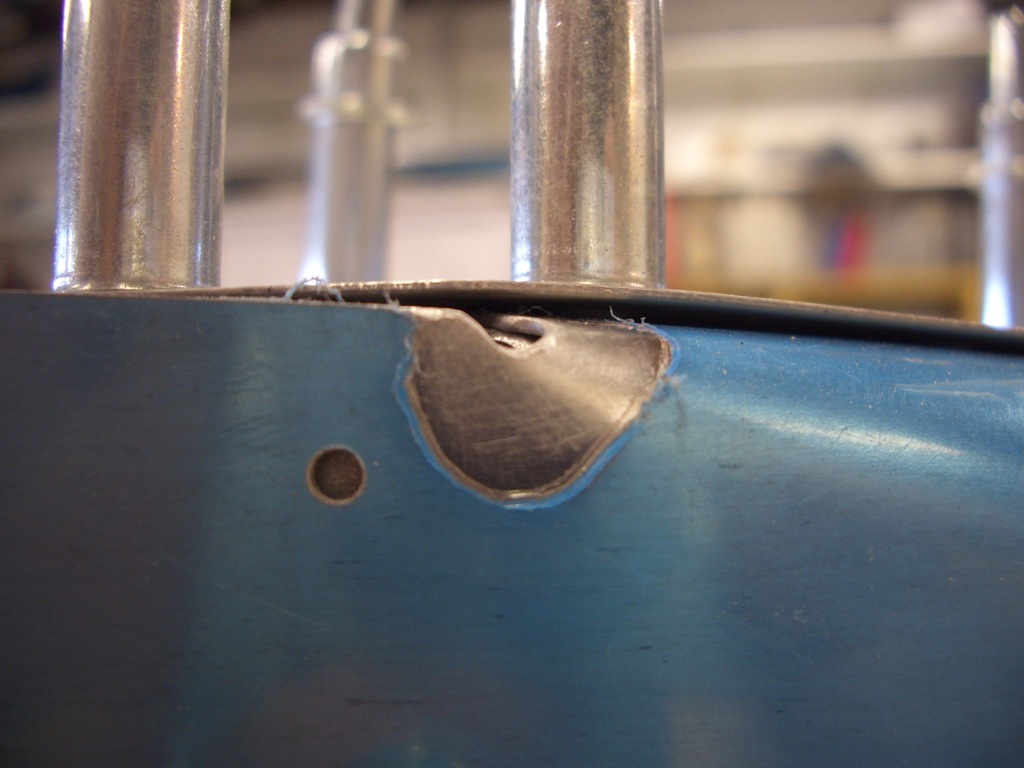

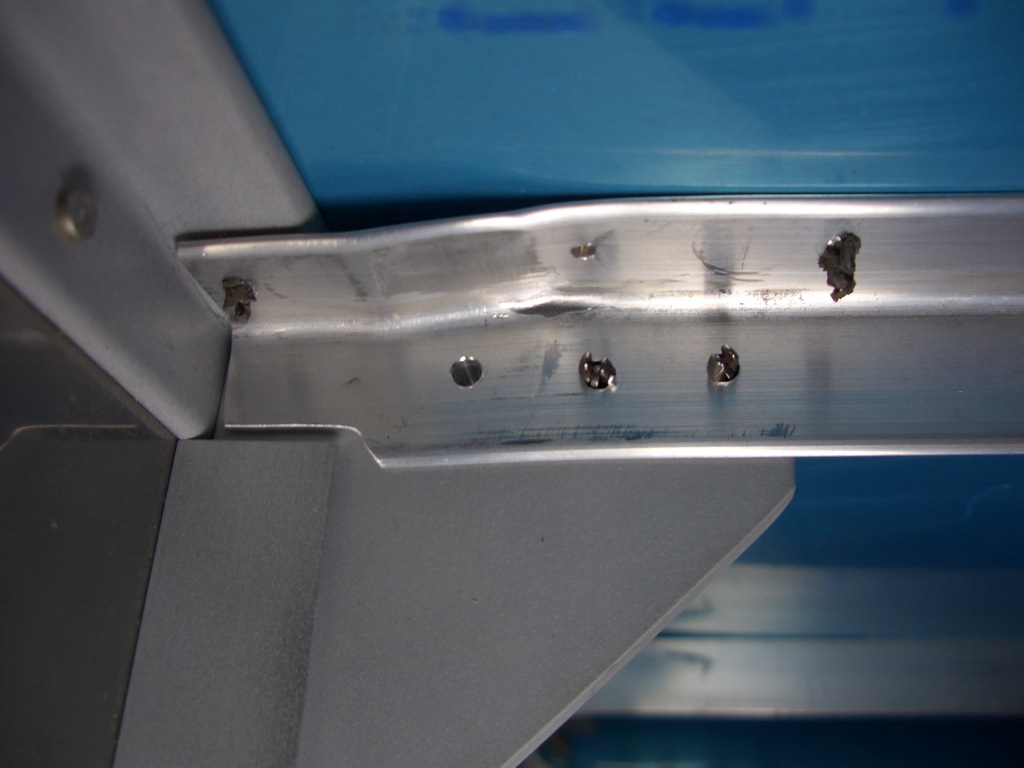

While deburring one of the skin stiffeners, I noticed this crack. I’ll call Van’s tomorrow and get another one sent. Hopefully, I can just use this one to match drill the new one so that I don’t have to reassemble the fuselage to drill it.

Here’s a shot from a slightly different angle. The crack goes all the way through and is visible from the inside as well.

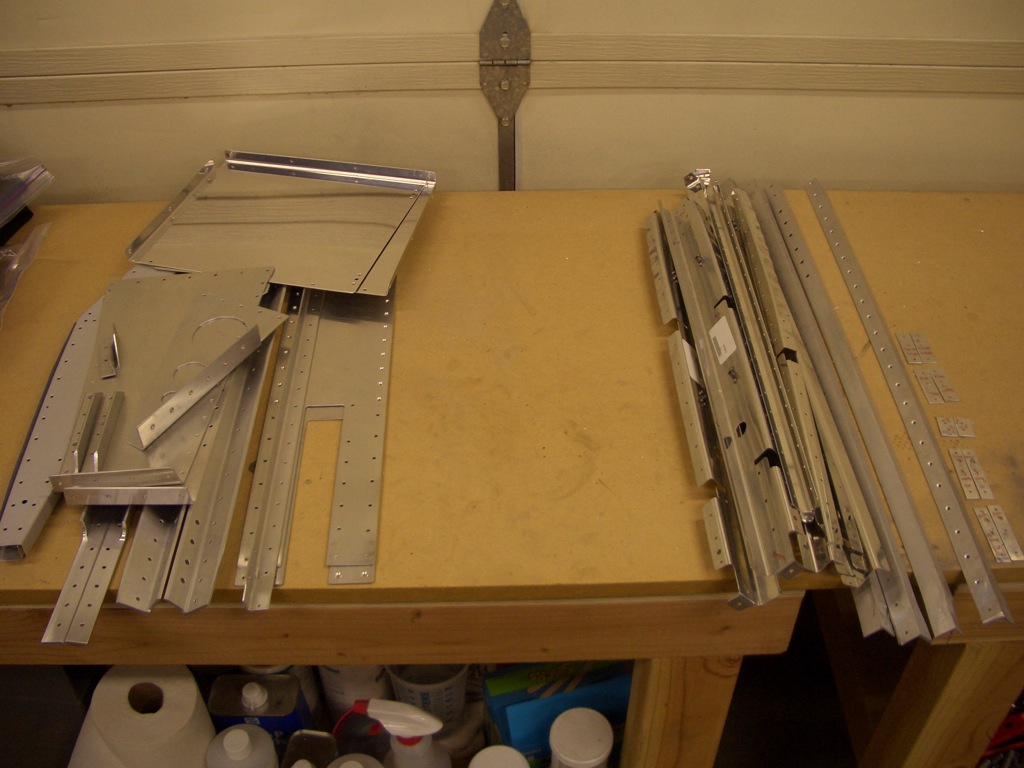

I made it through a good chunk of the small parts before calling it a night. All of the pieces on the left are deburred and dimpled/countersunk. I should be able to get through the remaining pieces on the right in one more session. I’ll still have the longerons to countersink (over 400 holes), and a number of holes in the tailcone and center section to debur/dimple.

Fit New Forward Bulkheads

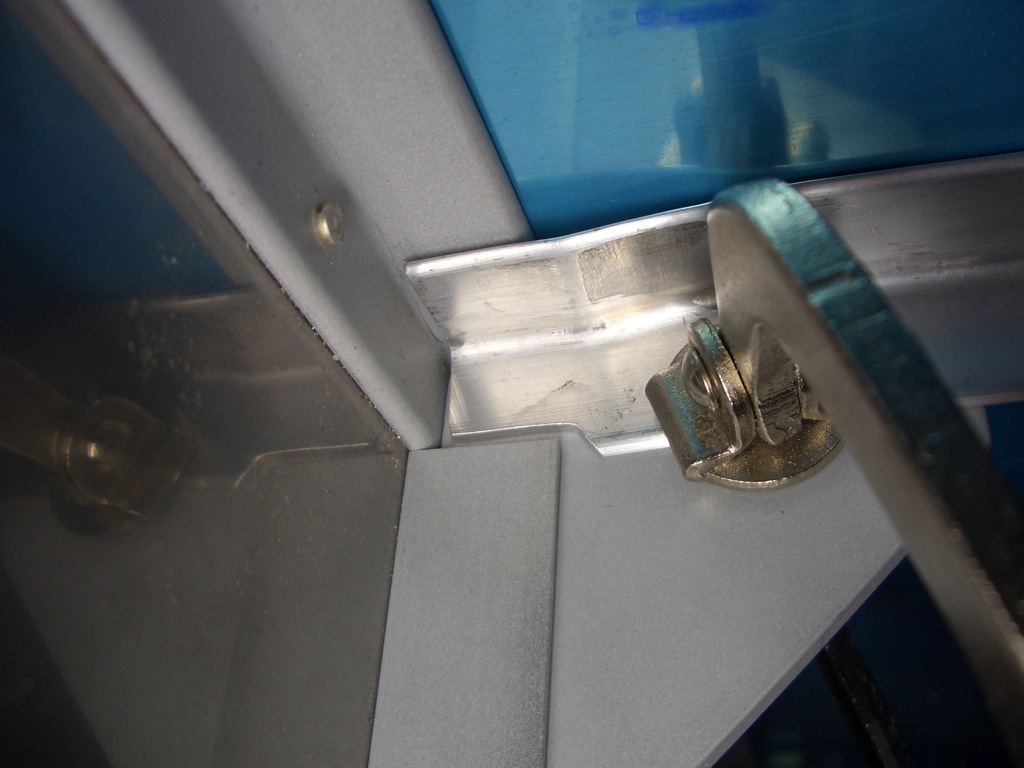

As I mentioned last week, I didn’t properly ensure I had the top edge of the gear web fully nestled inside the aux longeron before drilling the web to the forward bulkhead, so I ended up with significantly misaligned holes. I could have drilled the holes out for AN3 bolts, but access is tight there because of the reinforcing angle (see picture after this one) and it would have added significant weight. Anyway, I went ahead and drilled the gear web to the aux longeron (you can see the holes in the lower right of this picture) to keep the web tight against the longeron. I then match drilled the end flanges to the top and bottom longerons and then match drilled it to the gear web.

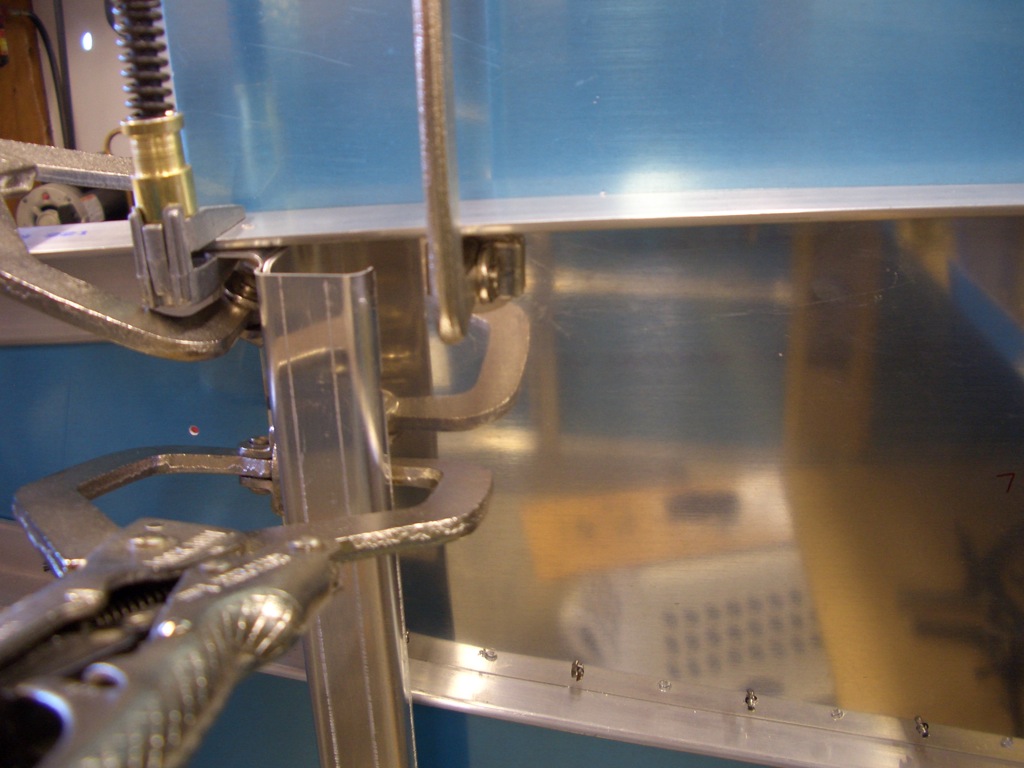

I finished fabricating the reinforcing angles where the forward tank attach bracket mounts.

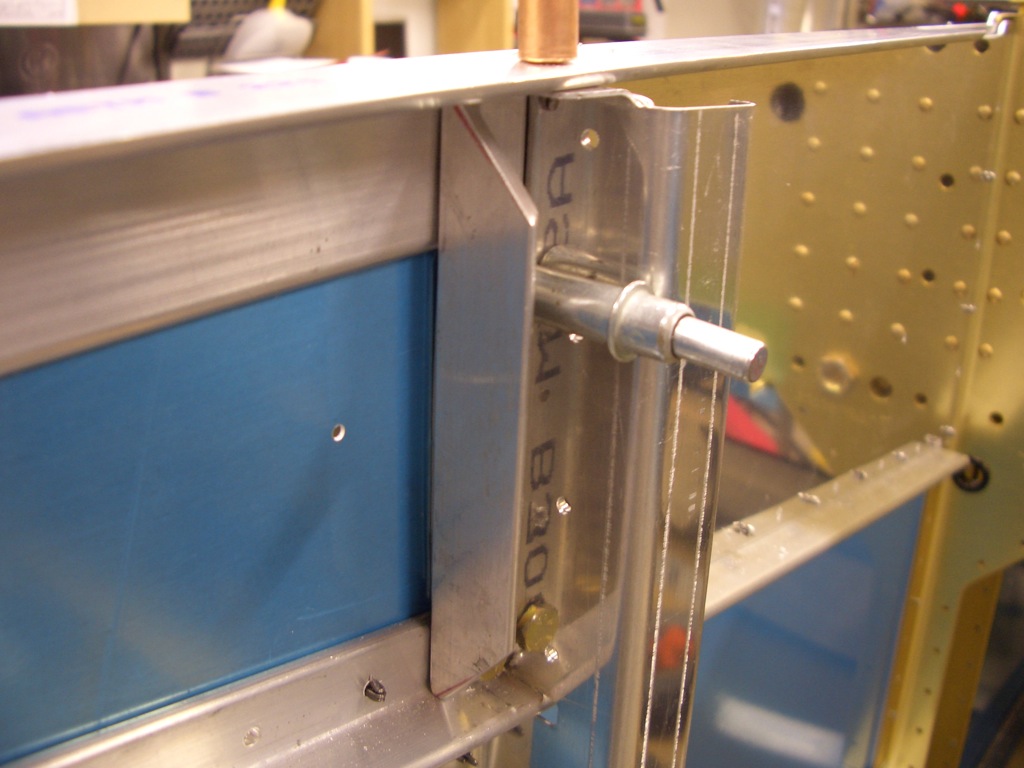

I drilled the upper hole (lower in this picture) to #15 and then reamed to 3/16″, then bolted the tank attach angle in place to drill the second hole through the skin, bulkhead, spacers, and angle.

Unfortunately, while drilling the second bracket, my #15 bit broke right as I finished the hole. Fortunately, the bit wasn’t jammed in the hole and came out easily.

I then bolted both brackets on with some scrap hardware to keep the reinforcing angle precisely in position for the final hole that needs to be drilled out countersunk for a screw. I’ll do that after the bottom skin is on though.

All of the fabrication work for the forward fuselage is done. I still need to match drill all of the skins and take care of a laundry list of small tasks, then this can all come apart for deburring, countersinking/dimpling, and priming.

Fit Baggage Ribs and Bulkheads

I fit the baggage bulkheads and ribs. Just like Mike Bullock ran into, I have a gap between the end flange of the baggage bulkhead and the side baggage floor rib.

However, unlike him, my bend wasn’t the cause. As you can see, the bend ended up perfectly flush with the side skin. Ignore the gap between the side skin and the bottom skin. That is just due to the dimples that are already in the bottom skin.

Since I didn’t have anything I could adjust to close this gap, I just cut some scrap 0.063″ sheet stock to make a shim. I intentionally made the shim oversize so that I didn’t have to get it precisely aligned to ensure adequate edge distance. After removing it, I’ll simply sand down the shim so that it’s no larger than the flange of the side bulkhead.

Ond of the baggage side walls needs to be clecoed in place to ensure the end flanges are positioned correctly before drilling. I then drilled the bulkhead to the side baggage floor rib. I ended up with only 1.5d on one of the rivets, but I’ve read that this is a common problem and most have even less edge distance.

I also drilled the other end of the baggage bulkhead to the longeron. This is another area in which I’ve seen other builders run into edge distance issues, but I ended up with 2d all around.

Finished Drilling Floor Stiffeners

I managed to drill the two outboard floor stiffeners by myself. The problem with these is that there is nothing to clamp them to. I ended up using some duct tape and a long stick to prop them up against the skin until I could get a hole at each end drilled. After that it was pretty straightforward.

The two center stiffeners also needed to be drilled to the cover support ribs at the aft end.

And they need to be drilled to the F-601J angles on the front end. DWG 19 specifies that these should be drilled in assembly with the floor stiffeners, but it would have been much easier if I had laid these out and at least drilled them out to #40 back when I was constructing the firewall. Oh well, I managed to get it done without too much pain.

Drilled Center Floor Stiffeners

I clecoed the bottom forward skin back on and pulled out the floor stiffeners. Just like the side skin stiffeners, I had to use my hand squeezer and a couple of scrap pieces of angle to get these to sit flat on both the skin and the angle. The forward ends of the two center stiffeners also needed small relief cuts to clear one of the firewall stiffeners.

After confirming sufficient edge distance on the skin holes, I match drilled the stiffeners to the skins.

Here is a shot of the inside. The clamps holding these stiffeners to the beefy angle on the firewall and the cover support ribs on F-704 still need to be drilled. That will tie all of these structures together quite firmly.

More Deburring

I haven’t had much time this week due to various projects around the house, but I managed to get a little more work done on the plane tonight. I deburred a few more of the stiffeners and bulkheads and dimpled the tailcone. I should be able to spend a fair amount of time this weekend on the project.