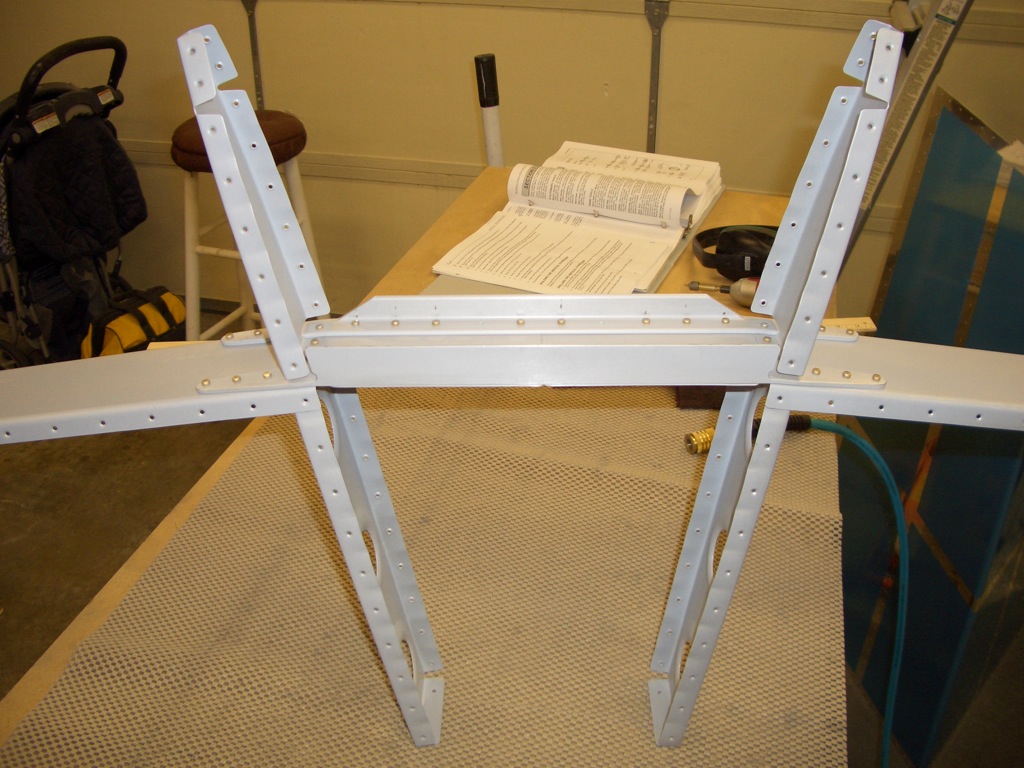

My buddy Andre was going to stop by later today to help me shoot the skin rivets on the vertical stabilizer, so I got started today riveting the rear spar together.

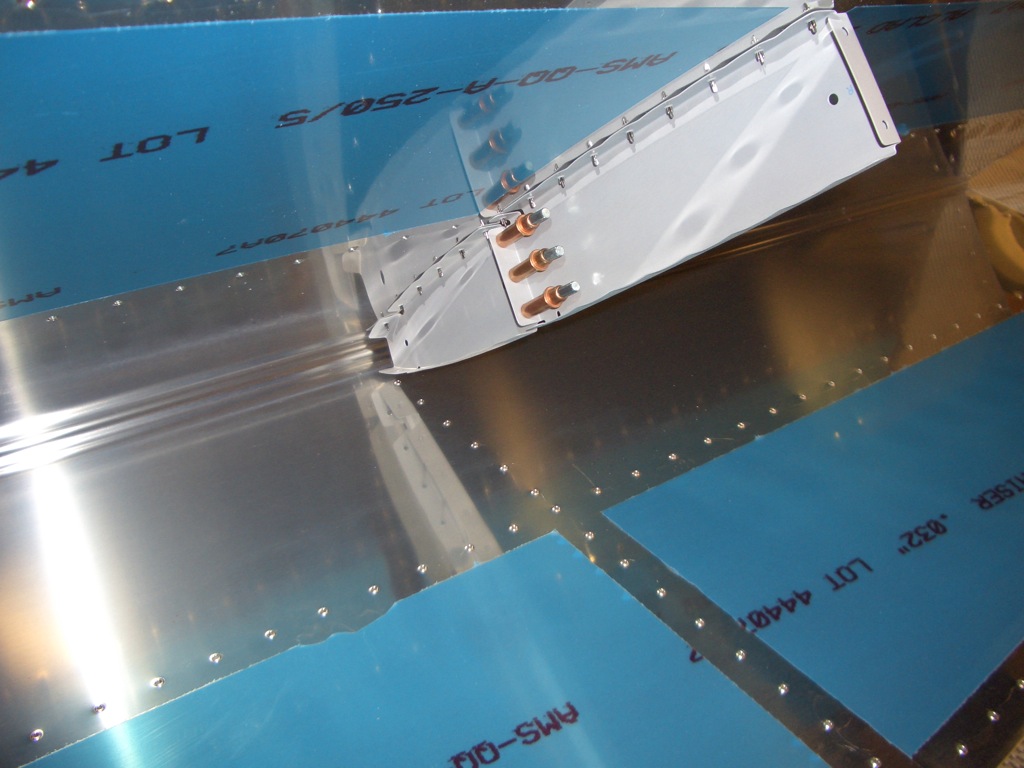

The lower part of the rear spar uses flush rivets because this section mounts against the rear fuselage bulkhead. The areas near the left and right sides of the picture which don’t have holes drilled yet will get holes drilled in conjunction with that bulkhead and will be bolted together.

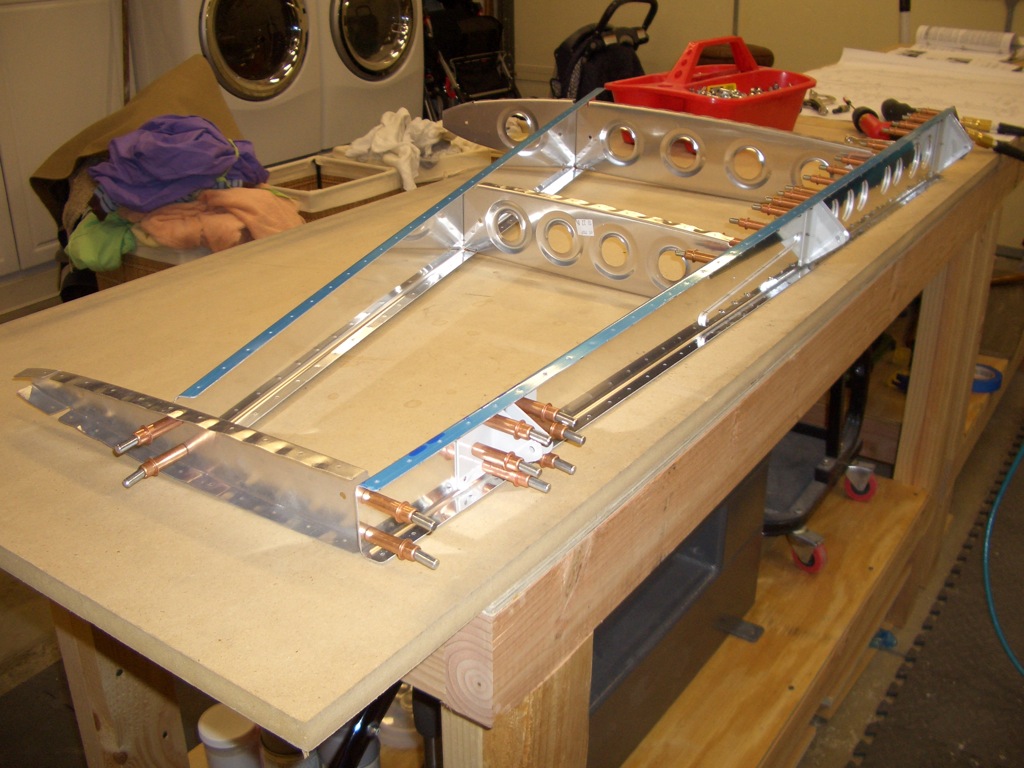

The interior structure has been riveted together here. Getting those rivets that hold the lower nose and main ribs to the front spar were a real bitch. I had to use a double offset rivet set to reach them (I suppose I could have bent both ribs out of the way and squeezed them, but I would have had to bend them a lot).

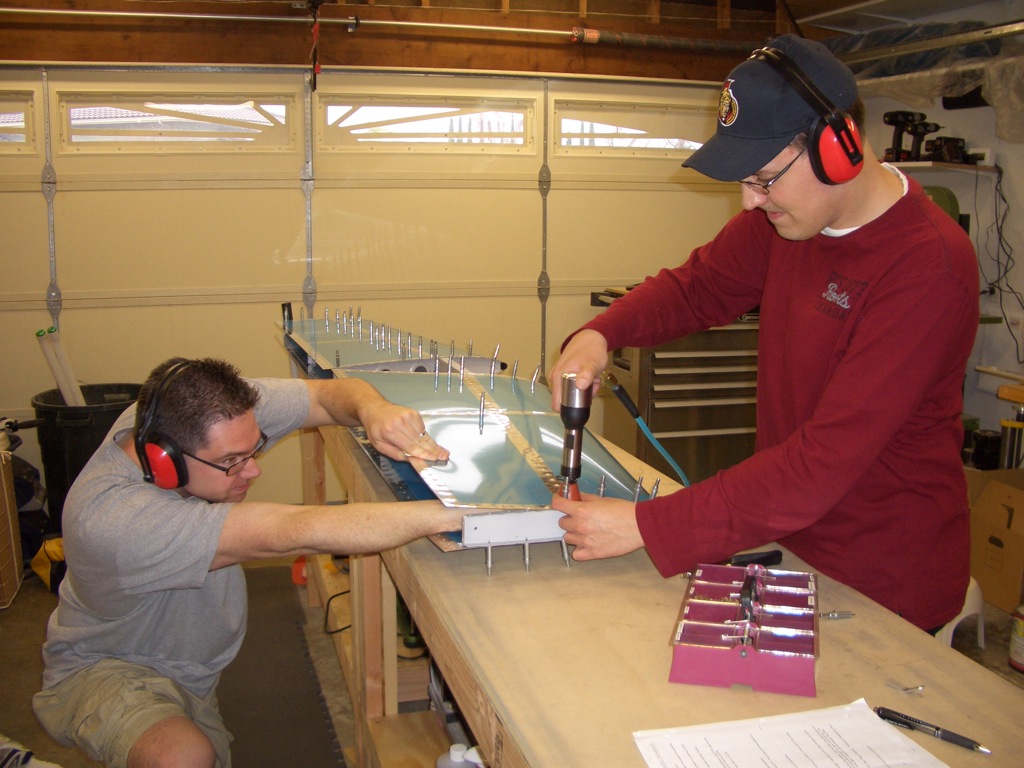

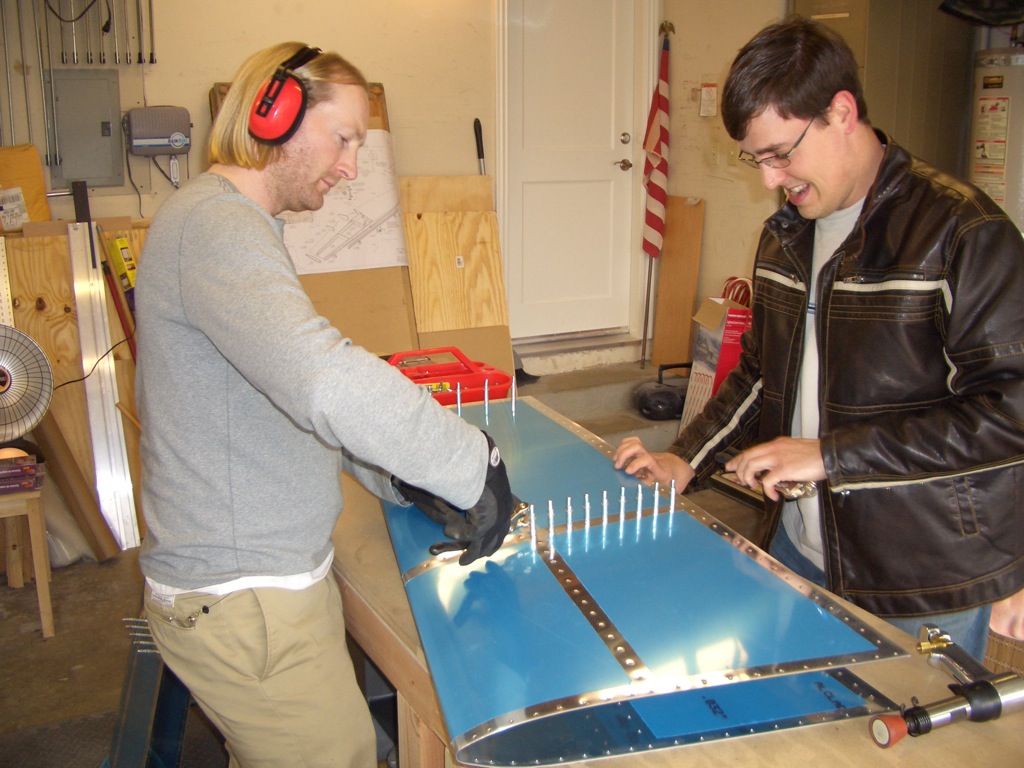

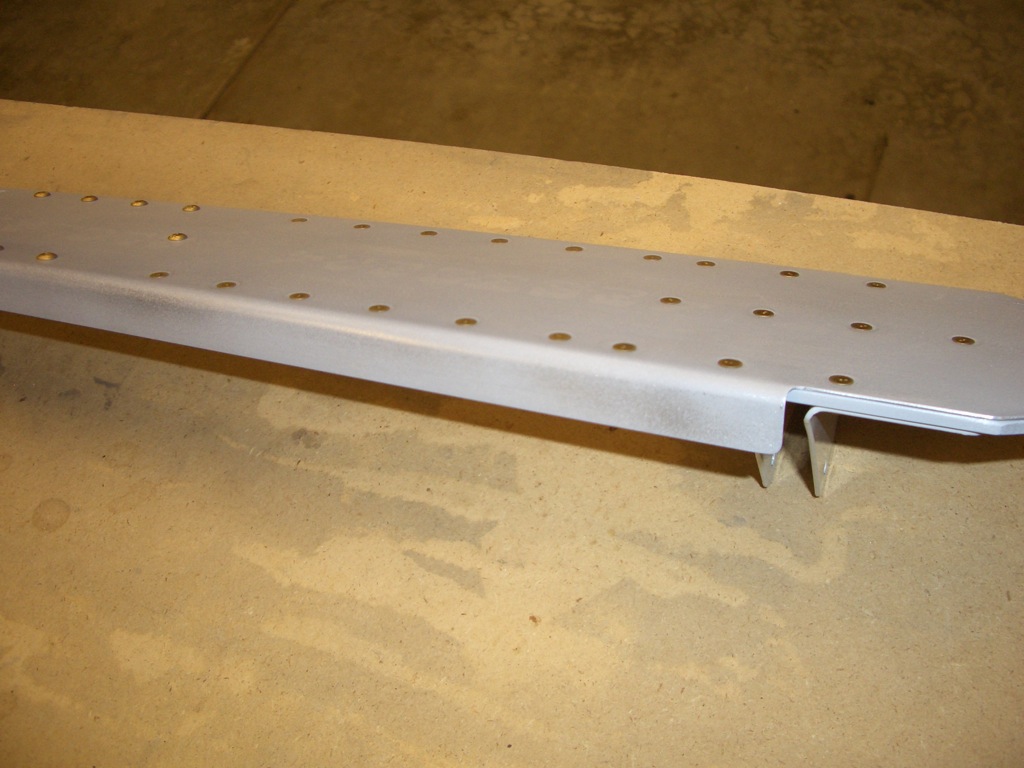

Andre and I shot and bucked the vertical stabilizer rivets that can’t be reached with a squeezer.